A Very Small World: Micromolding at Makuta

Makuta Technics sweats the tiny details so it can run ‘lights out’ most of the day.

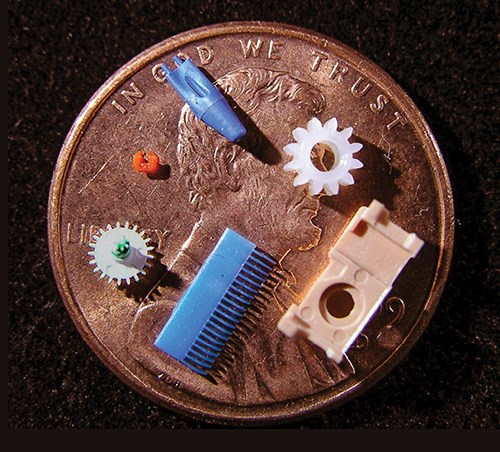

The parts range from flyspecks to thumbnail size or a little larger, and weights are often fractions of a milligram. Makuta Technics in Shelbyville, Ind., molds millions of them per month on 22 injection presses in a plant of only 22,000 ft2 with a suprisingly lean staff of just 14 people. Most of the time, there’s no one there at all—the plant runs “lights out” for two shifts out of three.

Two important facts about Makuta are not evident at first glance. First, despite its small size, Makuta is part of something big: It is affiliated—by family and business ties—with the Sansyu Group of Japan, said to be the oldest and largest micromolder in the world, a $100+-million business with a total of 500 injection presses and a similar number of employees at seven operations in Japan, Hong Kong, Indonesia, and the Philippines, plus a design center in Singapore.

Second, for a company that depends on automation to run things 16 hours a day in a plant empty of people, Makuta places strong emphasis on its human resources, emphasizing close collaboration, communication, and cultivating the individual talents of its team members.

HOW SMALL IS SMALL?

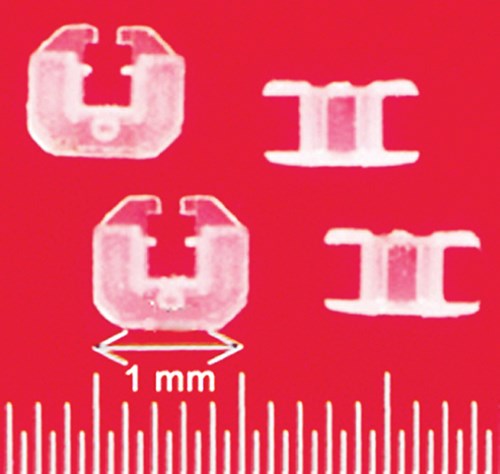

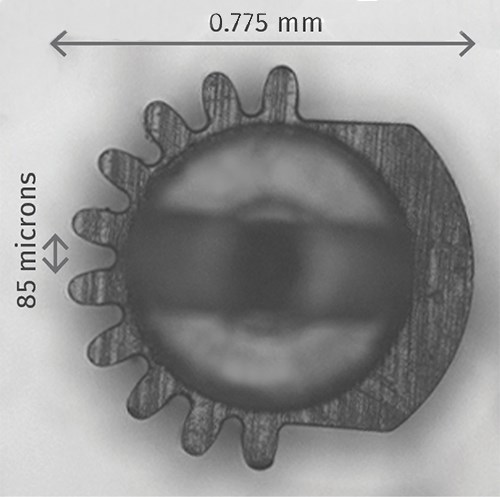

One of the smaller parts Makuta molds is a black acetal gear used in an ophthalmic surgery device. It weighs 0.524 g and measures 0.775 mm diam, with 85 microns (μm) between each of its 10 teeth. Another is an acetal bobbin for a miniature electric motor. It measures 1.11 x 0.64 x 0.94 mm and weighs 0.3 mg. Still another is a cylindrical acetal bearing for a computer printer roller, molded in four cavities; its wall thickness is 0.15 mm ± 0.015 mm and the concentricity spec is ± 7. 5 μm (0.0075 mm).

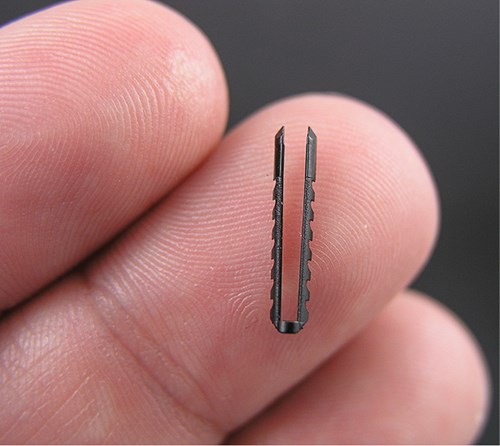

While these are mere specks, some parts are an order of magnitude larger. One example is a “barb stop” for colonoscopy procedures. This 0.772 g Ultem part is shaped like a bobby pin, 57.5 mm long, but the legs are at most 400 μm wide, and the end where they are joined has a 500 μm hole.

The biggest part molded here is a polycarbonate drug-delivery device, produced in two cavities, which measures 25 x 34 mm overall, but the mold has three different sliding components, all with features less than 200 μm, required to meet at one time. Another “big” part (for Makuta) is an AIDS testing device that’s a few inches in size but contains microfluidic channels 50 μm wide x 200 μm long.

“We define micromolding not by the overall size of the part, but by the size of the features or tolerances on the part, which for us are in the micron range,” explains Stuart Kaplan, Makuta’s founder and president. He cites the example of a diabetes testing device, which is matchbox size but contains 150 posts, each measuring 80 x 50 μm.

A little more than 10 years ago, Makuta was able to mold parts with hole diameters of 80 μm, and that was considered small. Today, the firm produces parts with hole diameters as small as 20 μm and many of its molds are built to hold tolerances of ± 5 μm.

“Our key concern, after 27 years in this business, is educating customers—designers and purchasing agents—about the special nature of micromolding,” Kaplan continues. “I often hear customers say, ‘You make small parts, so give me 72 or 96 cavities.’ But in order to attain the quality that we and our customers require, we run molds with two, four, and eight cavities—nothing above eight. Everything we make is a component that goes into something else, so the tolerances are critical.

“Micromolding is not a commodity business. It is so specialized that we don’t worry that a lot of other people will pile into it. We use machines that are available to anyone, but the key is how we use them. It’s a way of thinking.” Proprietary technique is such a big part of the business that material is less than 20% of a Makuta part quote—a fraction of what’s typical for “standard” injection molding.

A FAMILY AFFAIR

Kaplan’s father, who made large metal stampings for automotive fuel tanks and Sony TV sets, met Akiji Kamiya through an international metal stamping association. Tsuneichi Kamiya, founder of the Sansyu Group, made metal parts for analog watches. His son, Akiji Kamiya, moved the company into small plastic parts when the market switched to digital watches. The two families grew closer, and Stu Kaplan spent a year in Japan learning about plastics micromolding and eventually married Akiji Kamiya’s daughter.

Sansyu was interested in starting a U.S. affiliate. In 1993 Kaplan founded Sacoma Plastics in Columbus, Ind., with micromolding and metal-stamping operations to serve Japanese suppliers for a new Toyota assembly plant. Today there are seven Japanese Tier Ones in the area.

In 1996, Kaplan transferred the automotive micromolding business (two-shot buttons) to Sansyu’s Asian plants and sold off the metal stamping business. That year he started up Makuta Technics in nearby Shelbyville to focus solely on plastics micromolding.

Today, his micromolding business is quadruple the size of when he started molding buttons for Toyota (Kaplan does not release sales figures). The majority is medical components for hearing aids, drug-delivery devices, colonoscopy instruments, microfluidic applications, diagnostic devices, surgical devices, and DNA sequencers. Makuta also has substantial business in parts for printers, copiers, laser cartridges, and cameras.

Makuta makes a lot of parts, even if some of them are barely visible to the naked eye. Typical volumes for an individual job can be 80,000 parts a day, up to 700,000 a month. Some jobs run as few as 3000 parts a month.

Makuta specializes in using unfilled high-temperature thermoplastics like PEEK and Ultem PEI. It is also the only micromolder certified by DuPont to injection mold Vespel polyimide, a special high-heat-resistant resin used in antilock brake components. (It is so high in viscosity that Makuta purges it with Ultem.) Recently, Makuta began molding glass-filled PP, which is exploring new territory for the company, because it exposes its delicate molds to wear from the glass fiber.

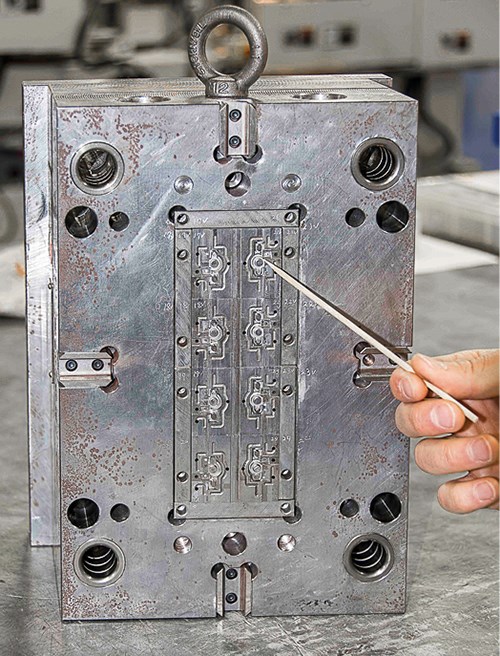

Those molds are all made for Makuta by Sansyu’s moldmaking operation in Japan. Sansyu has 20-micron wire-EDM capability, 3D laser sintering to make conformal cooling channels, and a CT scanner to compare tooling dimensions with the original CAD model.

Although Makuta’s molds have only a few cavities and can be held in your hands, they can be devilishly complex. The tooling consists of core/cavity inserts for standardized mold bases. But each core/cavity set can comprise up to 30 separate inserts. “Making them of multiple parts instead of one-piece has advantages,” says Kaplan’s son Andrew, who has been an intern in the business for the past year. “If one piece gets damaged it is easy and efficient to replace it, which is why we keep a lot of components in stock. Part of our mold quotation is an extra 25% for stocking replacement inserts.”

Makuta’s molds can have a lot of internal actions–up to eight slides, in fact. Instead of using a leader pin for guidance, Makuta uses linear bearings, which are said to cause less friction and wear, maintaining tight tolerances longer.

“When we first receive a mold,” says Tyler Adams, engineering manager, “we will break it apart and take measurements of what most molders would consider to be non-critical areas—those related to guiding. Then we will remeasure them later in production to check for wear. To maintain our tight tolerances, we’ll replace a $20 leader pin or guide pin without thinking twice about it. Most people in our business miss this concept.”

Typical mold vents are 7 μm in width and depth. “Venting is of huge importance to us,” says Adams. “That’s one advantage of our all-electric Sumitomo Demag presses: The Z-Mold Multitoggle function allows for profiling the clamp force from 2 to 18 tons within a cycle.”

For two-shot molding, Makuta uses Sansyu’s proprietary shuttling mold technology. It’s said to be more precise in its movements than a rotating mold plate.

Andy Kaplan notes that Makuta has very precise protocols for cleaning its delicate molds. First, they ultrasonically clean all inserts and injector pins. Then they finish cleaning inserts under a microscope with diamond paste and a thin, tapered bamboo stick. (It’s also used to push out inserts from the mold base for cleaning.) Mold plates are cleaned by hand with a fine grinding stone and mold cleaner.

Stu Kaplan adds that Makuta doesn’t use cavity-pressure sensors for the simple reason that the sensors are often bigger than their parts. “If you make the mold right, you won’t need sensors,” he states. “The electric machine will tell you what you need to know about what’s going on in the process.”

Makuta has 21 presses from 15 to 30 tons and one 50-ton “behemoth,” as Stu Kaplan puts it. A typical press has a 16 mm diam. screw and a nozzle with a 1.5 mm orifice. Most machines are dedicated to a particular job, so the plant is pretty fully booked, and at least three new machines will be on order by early next year.

Although Makuta still has some hydraulic presses, all new presses will be all-electric, says Kaplan, owing to their superior repeatability. Explains Adams, “Electric machines have less of a ‘personality’ than hydraulics. Every hydraulic press is different. And electric machines’ reporting of process data is excellent.”

He cites as examples of electric machines’ performance a study that showed over a run of 45,000 cycles that the standard deviation on screw starting position was ± 2 μm, on plasticating time it was 0.012 sec, and on holding-pressure end position it was 15 μm.

NEW TWIST ON SCREW DESIGN

All of Makuta’s—and Sansyu’s—machines come from Sumitomo (SHI) Demag (U.S. office in Strongsville, Ohio). Because of the molders’ close relationship with Sumitomo, they act as beta sites to try out new technology.

An important example is pioneering commercial use of the SL plasticating system from Spiral Logic Ltd. of Hong Kong (see Aug. ’12 Close Up). This novel system uses a zero-compression, 13:1 screw that “breaks the rules” by deriving all its energy for melting the plastic from the external heater bands, rather from shear heating in a compression zone, which is absent from this screw design. The SL screw works together with a special starve feeder that delivers a small mass of material to the screw on a first-in/first-out basis, and a special check valve that is said to provide 100% positive shutoff when the screw rotates 120° in the reverse direction—possible only with an electric screw drive. The seal ring does not rotate with the screw, avoiding wear.

This SL Screw Assembly, which is available for new or existing Sumitomo SE-EV and SE-DUZ all-electric machines, boasts several benefits. Eliminating the uncontrolled shear that reportedly occurs in conventional screws is said to provide more consistent melt temperature, density, and viscosity, while eliminating resin degradation and black specks, as well as random short shots. Reduced screw and barrel wear are also claimed.

Sansyu Group has more than 100 machines equipped with SL Screw Assemblies running PEEK and other materials for as long as three years. Makuta acquired its first machine, an SE30DUZ, with SL screw this past spring. It plans to purchase a two-shot machine with SL screws on both injectors. Stu Kaplan says the SL screw “does all it’s supposed to do; it’s very consistent from shot to shot.”

Adds Adams, “We did a two-day test run of an existing part and saw less variation with the SL screw assembly. Usually our process control detects a random short shot every 8000 to 10,000 shots; here we saw none in 10,000 shots. The test part has an orifice of 145 μm nominal diameter. The SL screw hit 144 to 145 μm consistently. “We also get no black specks in clear parts with the SL screw. In a standard machine, you can pull the screw and see carbon deposits in the compression zone.”

Adams believes the SL screw will save energy, and he envisions that it could prolong the time between mold maintenance stops by reducing resin degradation, offgassing, and resulting mold deposits.

Stu Kaplan plans to buy more SL screws and thinks it will become the standard for the shop. “It costs a bit more, but anything that makes processing more consistent, we’ll pay for that in a heartbeat.”

EVERYONE GOES HOME EARLY

Absolute consistency is essential to Makuta’s operations, because it runs only one manned shift a day. “Everybody leaves at 3:30 to 4:00 pm,” says Stu Kaplan. “Then it’s like Christmas every morning—we come in to a lot of parts made overnight.”

Samples of those parts are taken to the quality lab each morning and afternoon for visual and dimensional evaluation. Quality checks are also made every 2 hr in the first shift. Quality technician Jason Morgan is assisted in these tasks by Katelynn McIver and Iris Jimenez, both of whom started at Makuta as part-timers while in high school.

The purpose of the first shift is to get everything prepared for the next two shifts. Even then, only two people run the floor—technicians Sam Warren and Scott Turley.

During the “lights-out” shifts, if a machine can’t correct a problem within five shots, it will shut itself down and alert Warren or Turley via text or cell phone. “We want at least 85% uptime in overnight runs,” Adams says, “and our average has been 93% uptime.”

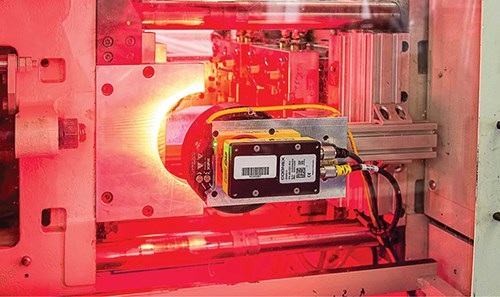

Unmanned operations require automation, most of which Makuta designs and builds itself, except for a handful of Yushin robots. Three of the latter demold parts in side-by-side automated cells enclosed in portable Class 10,000 clean rooms. These three cells mold two-shot syringe valves for highly caustic oncology drugs. The valve is of PP with a tip overmolded in TPE. The parts are made on custom-built, 30-ton Sumitomo machines with four-cavity molds that have 12 sliding components that interface with one another on each cycle. The highly detailed slide pins are required to interface perfectly with the core pin to ensure that no flash is allowed in the fluid path. Two Cognex vision sensors on either side of the mold measure the gate vestige in the most critical area of the part. The limit for a good part is 15 μm, but the cell is programmed to reject anything above 12 μm.

“We only use cameras because the customer insists,” says Stu Kaplan, because he is confident that Makuta’s mold technology and Sumitomo’s process control are up to the task. Makuta does use camera inspection on other jobs to protect expensive tooling by verifying that all parts are ejected.

Ben Rooks, manager of maintenance and automation, has a shop where he builds most of Makuta’s automation. Examples are a system for cavity separation on the printer roller bearing, where a robot deposits parts into openings of four hoses, and the parts are sucked by Venturi vacuum into separate receptacles. For another job, Rooks developed a system with a conveyor that fills two totes, using a timer to move the conveyor left and right to fill each tote with a precise amount of parts. And for the laser cartridge part, he built a turntable to hold multiple containers so that an exact number of parts would be deposited in each container during lights-out operation.

Makuta also has an FDM-type 3D printer for making robot end-of-arm tooling using ABS, because the firm’s microparts are considered too fragile to be handled with steel grippers.

WHAT’S A MAKUTIAN?

While he’s proud of what Makuta has achieved technically, Stu Kaplan is even more animated when discussing the people who work there. He has a name for them: “Makutians.” Kaplan explains, “It means you carry with you two core values. The first is an absolute desire to learn. We like to hire people with no molding experience—only the two technicians, Sam and Scott, had any rubber or plastics background. We want a blank slate, so we don’t have to break old habits of thought from molding parts like car bumpers, which are nothing like what we do here.”

Makuta developed and implemented an in-house “Pay for Knowledge” (PFK) training program. Staff personnel act as trainers, though trainees may also take courses at a local community college or engineering school. Among the PFK topics are these:

• Purchasing;

• Inventory control;

• Shipping/receiving;

• Single-shot molding;

• Double-shot molding;

• Forklift operation;

• Facilities maintenance;

• Mold maintenance;

• Quality;

• Robotics;

• Maintenance, Level 1;

• Maintenance, Level 2;

• Injection molding engineer.

One of those who benefited from the program is Lori McQueen, office manager. She started in shipping and now oversees that function as well as purchasing and inventory control.

The second Makutian core value, according to Kaplan: “You have initiative. Instead of waiting for someone to tell you what to do, you say, ‘I have this idea and what do you think of it?’ Perhaps it’s a new way to clean the floor, or weigh tiny parts, or not weigh them but use laser counting instead. Even our high-school interns come up with suggestions. We have a lot of young people here, and if I were telling them what to do, I would lose the resource of their intelligence. Selfishly, I want people to think for themselves and grow—they’ll do things much better than I could.” Employees’ suggestions can benefit the individual as well as the group through the firm’s profit-sharing program.

Besides learning and initiative, Kaplan cites a third key word in the Makutian philosophy: “Communications are critically important here. When I was young I worked in plants where the first shift blamed the second shift, which blamed the third shift for problems. We don’t have that here.”

For example, anyone who wants to make a change in a process must first fill out a “6M” form. The six Ms are Mold, Machine, Method, Material, Measurement, Man. Completing the 6M check involves every function within the company to make sure that all are aware and can comment on how each function would be impacted by the change.

There’s also the daily 9:00 am meeting, where all the employees stand in a circle and update each other on what happened overnight and what is planned for the day ahead, including who might be absent and why and what consequences that might have for the shop.

Adams explains that a Makutian is “somebody who holds absolute responsibility to every other member of the group. I can’t be watching how everybody else does their jobs, so I have to depend on them. I’m in engineering, but shipping, for example, is also super important.”

Among other interpretations of the Makutian ideal, Andy Kaplan says, “You want to make all our lives better from a practical standpoint. You’re always thinking how to make the place cleaner, make processes run better. For example, one part suffers from terrible static, which causes problems on every run. So on each run we try something new, change some small detail, to try to combat static.”

Says Katelynn McIver, “We’re all really caring. Willing to work and learn. We’re a family.”

Adds Scott Turley, “We get to think for ourselves more than at any other place where I’ve worked.”

Related Content

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreRead Next

New Injection Screw Breaks the Rules, But Fixes Many Molding Defects

“Revolutionary” screw design turns conventional plastication theory upside down.

Read MoreNew Injection Screw Breaks the Rules, But Fixes Many Molding Defects

“Revolutionary” screw design turns conventional plastication theory upside down.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)