Advancing Composites in the Black Hills of SD

The CNAM Center at the South Dakota School of Mines seeks to act as a nucleus for composites manufacturing.

When you think of South Dakota, Mount Rushmore, Sturgis and Deadwood all come to mind. But a group at the South Dakota School of Mines & Technology hopes that one-day South Dakota is also viewed as a national and global hub for advanced composites manufacturing R&D. The Composite and Nanocomposite Advanced Manufacturing (CNAM) Center at the South Dakota School of Mines & Technology in Rapid City was launched in September 2013 with a goal to help maximize the potential for composites manufacturing. Funded through a five-year award from South Dakota Governor’s Office, CNAM includes the participation of a consortium of corporations, which features three processors (Falcon, Brookings, SD, Continental, Auburn Hills, Mich., and Raven, Sioux Falls, SD) as well as PolyOne, Avon Lake, Ohio.

“What is compelling about CNAM is the overall intent to bring composites more into the mainstream for applications like transportation, infrastructure and energy,” Joe Golba, lead scientist, reactive extrusion at PolyOne told Plastics Technology.

The market penetration of composites compared with steel and aluminum is still below potential. CNAM believes this is a combination of both expensive raw materials as well as a high manufacturing cost.

“We need to get the cost down of composites—both the materials and manufacturing cost,” said David Salem, director of CNAM. “We believe that CNAM can make real advancements in this area.”

Why CNAM? Well, Salem says CNAM is an industry-driven center and its overall goal is to see the fruits of CNAM’s research and development go to the market. As the membership covers the entire supply chain, Salem says there is a great deal of collaboration in the center.

CAPE LAB

The School of Mines is home to the Composite and Polymer Engineering (CAPE) Lab, which features almost $10 million of advanced equipment in 10,000 square feet of laboratory space. From a Cincinnati Milacron injection molding machine to a Taricco industrial autoclave for composite curing, the CAPE Lab features plenty of polymer and composite processing and prototyping equipment. In addition to a number of graduate students, CAPE employs full-time, dedicated composites scientists and engineers.

TECHNICAL WORK

One interesting development to come from CNAM includes the development of a new manufacturing process for discontinuous fiber-reinforced thermoplastic sheet (CNAM-DiFTs). Provisional patents related to process and properties were filed on Aug. 11. (To view more about this process, check out PT’s New Process for Fiber-Reinforced Sheet.

CNAM is also working on a practical method to fabricate hybrid multi-scale –composites using in-situ polymerization of CBT, incorporating electrospun glass and carbon nanofibers combined with glass and carbon microfibers. Other work includes a model that has been developed to predict fiber orientation in injection molding processes, which has been demonstrated in case studies. Orientation predictions are being output into software to predict strength and failure based on orientation pattern.

Salem says that the IP developed at the university belongs to university, however, member corporations have exclusive rights to use the technology on licensing terms to be negotiated, and have first right of refusal.

The CNAM Center is interested in expanding its membership to additional corporations. If your organization is interested in participating or would like more information, contact David Salem.

Related Content

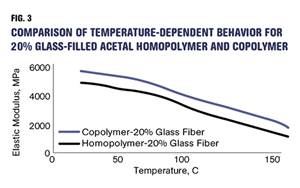

How Do You Like Your Acetal: Homopolymer or Copolymer?

Acetal materials have been a commercial option for more than 50 years.

Read MoreThe Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreTracing the History of Polymeric Materials: Aliphatic Polyketone

Aliphatic polyketone is a material that gets little attention but is similar in chemistry to nylons, polyesters and acetals.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)