Barrel Repair: When Does It Make Sense?

Repairing a barrel can save you time and money vs. buying a brand-new one. But it’s not an easy fix and not even always possible.

Refurbishing a worn extrusion or injection cylinder rather than replacing it with a new one can save money and delivery time. Under the right circumstances, the savings can range from 25% to 50% of the cost of a new barrel. But the benefits of repair are not available for every barrel or even most of them. Whether or not repair can be a viable alternative depends on several factors, starting with the type and size of the barrel.

The repair process is a kind of remanufacturing, and it can sometimes approach the production of a new barrel in terms of cost to the customer. Because new extrusion barrels cost less than those for injection molding, there is frequently little margin for savings compared with buying a new barrel. On the other hand, very large or elaborately equipped extrusion barrels (for instance water- or oil-jacketed barrels, pin barrels, or large rubber mixers) may cost significantly less to repair relative to the original equipment price.

The economics are more favorable for repairing injection molding barrels, particularly since repair often involves relining only a short portion of the entire barrel. Typically this “short sleeve” is installed at the discharge or stroke end of the barrel near the check ring, an area that is especially subject to wear and resulting leakage. Such leakage makes it difficult to control shot size. As a rule of thumb, when the wear in an injection barrel reaches 0.020 in., it is time to repair or replace the barrel. For critical molding applications, the cutoff point may be as low as 0.003 in. In extrusion barrels, by contrast, the level of wear can range up to 0.250 in. for very select applications.

Nowadays, many injection barrels that might have been repaired in the past are being replaced instead. With modern manufacturing methods and productivity improvements, the cost of new bimetallic barrels has come down, and the performance demands placed on the barrels are much greater. Where once pressures of 20,000 psi were standard, today 35,000 psi is common. In addition, part requirements—dimensional tolerances, avoidance of flash, and other quality parameters—have become more stringent.

The process of repairing a barrel requires the removal of a portion of its inner wall—the metal surrounding the bore or screw channel—and replacing it with a newly manufactured, thin-walled bimetallic sleeve or liner. It is absolutely essential that there be an extremely tight metal-to-metal fit between the liner and the original steel. Few companies know how to accomplish this. A repair by an inexperienced company or a “corner-cutting” repair can adversely affect the molding or extrusion process and the quality of finished products.

Producing a liner or sleeve actually involves all of the steps needed to make a new barrel, with the exception of some final machining steps and millwork. The overall repair process is as follows:

• The barrel is placed in a boring machine specially built for rigidity to prevent vibration while a long boring bar and special boring head are used.

• The inner wall of the barrel is bored out so that the resulting bore is approximately 1.0 in. larger than the original bore. This step is particularly difficult, since it involves boring through the extremely hard bimetallic inlay, along with a portion of the backing steel that makes up most of the thickness of the barrel. Boring has to be accomplished while maintaining straightness of approximately 0.005 in. TIR.

• A new bimetallic liner is machined to approximately 0.5 in. wall thickness, maintaining an OD tolerance of 0.001 in. The liner, which consists of a hard bimetallic inlay material plus backing steel, has an OD that is actually slightly larger than the ID of the bored-out barrel.

• Through a special heat-shrinking process, the liner is secured with an interference fit inside the barrel.

• Final machining and polishing takes place. Ask your supplier to take the extra step of re-machining the installed barrel liner to ensure concentricity.

Even when produced under the most exacting conditions, a repaired barrel never quite achieves the degree of straightness, concentricity, strength, or heat transfer available with a new one. When straightness is greatly compromised as a result of a poorly done repair job, it can lead to accelerated wear.

Another risk involved when a repair is not carried out properly is that an air pocket is left between the liner and the outer barrel, causing heat transfer issues, which in turn lead to process problems. Alternatively, a poor fit or a gap between liner and barrel can lead to an incursion of polymer into the interface.

In the case of short-sleeving, seams or cracks are built into the barrel at the site where the sleeve meets the existing inlay, creating the possibility for polymer to hang up and degrade.

Deciding whether to repair or replace a worn barrel is often not a simple matter. The supplier can help molders and extrusion processors make the most appropriate decision. In some cases, the availability of expert repair capabilities may prove to be a valuable resource.

Related Content

Green’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

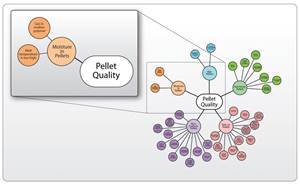

Read MoreThe Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

Read MoreLFT-D Thrives in Automotive and Other Durables

Teijin Automotive acquires its 10th direct long-fiber thermoplastic system as demand for this technology soars.

Read MoreWhat to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More