Better, Not Bigger, Is How Copol Wins In CPP Film

On Site

Small player in a large market speaks in a loud voice.

For Copol International Ltd., the future is all about providing highly customized cast polypropylene (CPP) film. So, for that matter, is the past and present. Since its start-up date 20 years ago, when it took over a plant in in Cape Breton, Nova Scotia (Canada) that had been producing PVC stretch film, Copol (copolinternational.com) has been about CPP and only CPP.

In North America, CPP is not as widely known as its so-called big brother, biaxially oriented PP (BOPP). That said, CPP film has been penetrating traditional packaging and non-packaging applications. These range from side-weld-seal bags to stand-up reclosable pouches, candy twist wrap, document protection, and sophisticated multi-layer laminations. CPP also can be metalized for barrier applications where product shelf-life is a key factor.

CPP film is known for its high gloss, exceptional optics, excellent heat-seal performance, high heat resistance, good dimensional stability and barrier properties, pliability, and excellent printability. These performance factors are combined with outstanding yield and economics.

“CPP delivers a unique set of properties, notably high-temperature resistance and excellent stiffness and clarity,” notes Denis Lanoë, Copol’s v.p of operations and general manager. “This is the marketplace niche on which we are focused. And by being focused, we are able to develop synergistic relationships with our customers and our suppliers that might not be possible otherwise.”

To that point, Lanoë notes that both of Copol’s primary material suppliers, LyondellBasell and ExxonMobil, have used Copol’s production equipment as an extension of their own R&D operations to test new resin formulations and film structures.

Copol still operates out of the former PVC stretch-film plant, using 80,000 ft² of manufacturing space to produce dozens of CPP film structures from three single-layer lines and one three-layer line. Due to be commissioned late this summer or early fall is a brand-new five-layer, Filmex cast PP line from Windmoeller & Hoelscher, which will provide Copol with the capability to expand its offerings to current customers and develop altogether new ones.

“We have enjoyed much success over our history, but we are not resting on our laurels, says David Sawler, v.p. of business and product development. “Consumer demands are changing and packaging is changing to meet those new demands. To be on the leading edge of the CPP film industry, we need to expand our manufacturing capabilities and focus on new, value-driven product development. We want to play a major role in shaping the direction of the industry, and investing in this type of advanced equipment will allow us do that.” The new W&H line will eventually permit Copol to produce CPP with up to nine layers.

Sawler continues, “The company has committed to new processing technologies and we are constantly evaluating new resin and additive technologies. Our continuous focus on innovation and development of new film products and services will deliver market-leading performance and value to our customers.”

LIGHT ON ITS FEET

That’s not to say that Copol is an industry behemoth that clubs competitors based on overwhelming volume. Copol keeps its annual sales figures and production capacity close to the vest, but the firm’s strategy is more about being fast and flexible than big and dominating. “We’re a small player in a large market, but we speak in a loud voice,” is how Sawler puts it.

“The value proposition of what we deliver to the market is widely known,” he elaborates. “We may not sell the most in terms of pounds, but I would say we have the most customers. Not everyone can buy 20,000 lb of film at a clip. Some order 100 lb of material at a time, while others order a full truckload.”

Adds Bill Daehler of Northstar Films, Copol’s exclusive U.S. sales agent, “We consider ourselves unique because we always have much more production capacity than we need. As a result we can offer lead times of two or three weeks to anywhere in North America. That speaks to our focus on the customer.”

PRODUCTION CAPABILITIES

In Nova Scotia, Copol has steadily upgraded both the hardware and controls of all four of its cast lines. The addition of the new W&H line will expand the company’s film gauge range from 0.7 mil up to 6 mil.

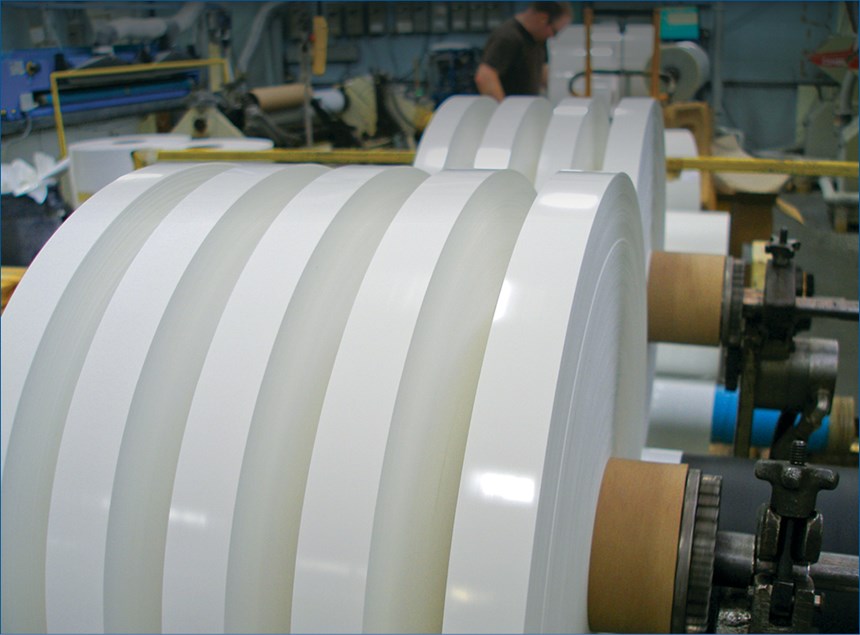

It has a standard line of CPP films combined with the knowledge, technology, and analytical capabilities to develop totally new structures for highly customized applications. Copol operates multiple slitter/rewinders that can produce custom finished rolls ranging from 0.75 in. to 72 in.

Copol determines the optimal resin/additive packages for each application, but it also works to ensure that alternatives are always available to strengthen supply-chain management. “This broad portfolio of resin/additive packages allows for product customization to meet specific and unique requirements,” Sawler states.

“We differentiate ourselves by customizing an existing product to meet specific client performance parameters, or by developing a new product that best delivers specific performance parameters,” states Sawler. “With either approach, that helps our customers differentiate themselves and strengthens their positions in the market.”

Of course, manufacturing plays a pivotal role in CPP film development. Because of the depth and breadth of the product range, there is no such thing as a dedicated production line at Copol. The firm will combine orders from various customers in a single production run as needed, says Lanoë.

Compressed lead times have encouraged Copol to innovate in areas beyond manufacturing. “About 95% of our business is door-to-door,” states Daehler. “With so many different products of different quantities going to different places, the logistics can be very challenging.”

Dahler continues, “The logistics component of managing a relationship is just as important as delivering quality and consistency. So when a customer places an order with us, we have developed a process whereby everything is scheduled at the same time: extrusion, slitting, up to and including the space on the truck that we will need.”

AGILITY, INNOVATION

With rising consumer demand for convenience-food preparation and “meals ready to eat,” Copol offers a series of CPP film products used primarily as sealant layers in multi-layer laminate structures for retort applications.

Copol’s RP423BX series of coextruded CPP film products takes aim at the growing and technically demanding freezer-to-microwave steam cooking market. They are used in laminate structures with converter-proprietary, self-venting mechanisms designed into the final package. The basic film material (offered in both white tint and clear) combines toughness and a broad operating temperature range. It offers excellent low-temperature impact properties down to –10 C while at the same time offering high heat resistance up to 150 C.

Available products include a clear, slip-modified, three-layer, impact-copolymer-based film offering good contact optics and good impact properties down to –10 C. A white tint version that maintains all of the other properties of the clear product is also available.

Never satisfied with the status quo, Copol is also combining innovation with new processing capabilities to develop new CPP film products for ever more demanding packaging applications.

The first series of Copol’s new multilayer films will target lidding applications with the combination of exceptional sealing performance and predictable and consistent peel characteristics. This class of product will enhance packaged product freshness and security while at the same time offer convenience of opening for the consumer.

The second series of multilayer films will combine exceptional optical properties with improved low-temperature performance.

Copol also has the capability to micro-perforate virtually all of its CPP film products using hot-needle perforation technology. Besides the traditional in-store bakery and fresh-produce applications, micro-perforated CPP is finding its way more and more into food cooking applications, both for “boil-in-a-bag” and microwave cooking.

Related Content

Specialty Purging Compounds Optimize Color and Material Changeovers

Selecting of the correct purging compound can speed up material and color changeover time and reduce scrap. You’ll even save on material.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

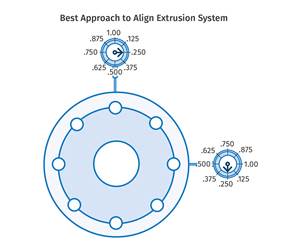

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)

(1).png;maxWidth=300;quality=90)