Biodegradable Bioplastics Continue to Evolve

Root vegetables, shrimp shells, proprietary starch formulations and natural fibers are among the emerging global bioplastics.

Root vegetables, shrimp shells, proprietary starch formulations and natural fibers are among the emerging global bioplastics.

Just a few days ago, I blogged about yet more work underway on the development of man-made bioplastic chitosan derived from the organic compound chitin extracted from shrimp shells, this time for the production of biodegradable shopping bags and, ultimately, future-generation food packaging.

And, while PLA continues to make ‘leaps and bounds’ in a broader range of applications, including disposable, consumer durables and 3D printing, intriguing work on bioplastics (particularly biodegradable varieties) derived from other sources is also being pursued globally.

Cassava Root Bioplastic

One example comes from Avani Eco, a three-year-old Balinese company that sought to address the plastic pollution strewn on Bali’s shores and expanding landfill sites that has threatened to make the island a “paradise lost”.

A key focus for the company was to address the single-use plastic bag problem by producing biodegradable, compostable and recyclable bags made from a bioplastic that is based on cassava root, a cheap and common root vegetable found across Indonesia.

The company currently produces four tons of material a day that is used for products including plastic bags, food packaging, covers for hospital beds, and rain ponchos—an original aim to replace the popular PVC ponchos used on the island.

Avani Eco’s cofounder Kevin Kumala and his partner were inspired by bioplastics based on corn and soy starch and came up with a formulations using cassava starch, vegetable oil, and organic resins. The result is a 100% bioplastic that is biodegradable and compostable, with the capacity to break down over a period of months on land or at sea, or instantly in hot water. This bioplastic is said to leave no trace of toxic residue. Avani Eco has amassed several hospitality and retail partners including local hotels like Hard Rock and Ritz-Carlton, juice bars, and music and other social festivals.

Starch-Based Elastomer

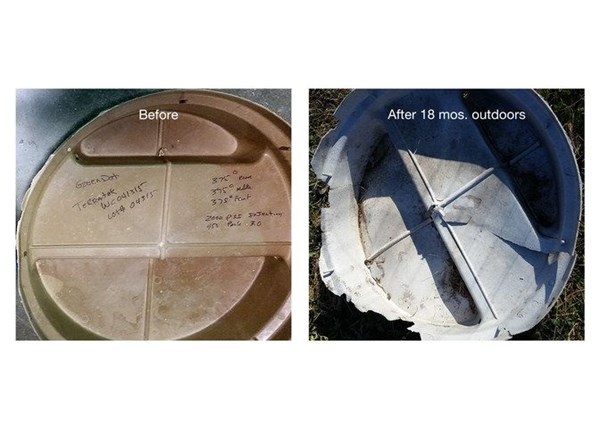

Meanwhile, Green Dot Bioplastics, Cottonwood Falls, Kansas, which has developed a full line of biobased and compostable materials sold under the Terratek Brand name, continues to expand its product line and further develop novel materials.

That has included Terratek GDH-B1 a starch-based elastomer which has been used for products like cellphone cases and toys, and as an impact modifier for PLA. Just this month, the company unveiled a new biodegradable bioplastic composite created as a sustainable replacement to traditional plastic plantable pots or tree and shrub containers. According to CEO Mark Remmert, it is based on a proprietary blend of starch-based polymers reinforced with natural fibers—in this case, wood or corn cobs.

Unlike compostable planters made of paper, peat or cardboard which are absorbent, requiring plants be watered more often due to evaporation, planters made with Terratek BD2114 do not absorb water, helping retain moisture in the potting soil and potentially reducing water consumption by as much as 600%. The material is also easily colorable to enhance product differentiation.

According to Remmert, in developing the new material, the company also aimed to compete with other biodegradable bioplastics such as PLA. The new “biocomposite” allows for the production of molded pots which have higher impact for longer shelf life; are more degradable; and are less expensive, says Remmert. Moreover, the company can provide custom formulations of biobased and biodegradable materials to fit a broad range of horticultural applications.

Related Content

Tracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.

Read MoreFast-Cycling Selective Laser Sintering System

Nexa3D announced the QLS 260 for metal and polymer production.

Read MoreTracing the History of Polymeric Materials, Part 25: Silicones

The long road to the development of silicone resulted in a chemistry that is remarkably versatile.

Read MoreBiobased TPU for Broad Range of Applications

BASF’s Elastollan N contains 50% renewable raw material.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)