CAD & CAE

NPE 2000 offered a brand-new option for processors and mold designers: the ability to “rent” flow analysis on a pay-per-use basis over the Internet.

NPE 2000 offered a brand-new option for processors and mold designers: the ability to “rent” flow analysis on a pay-per-use basis over the Internet. And when a perfectly balanced mold refuses to fill evenly, a new type of runner flow analysis can diagnose and solve the problem. Also introduced were quick and easy cooling-time estimators and affordable mold-design software.

For flat-die extrusion, enhanced flow simulation now handles five-layer coextrusion. There’s also a new rapid-prototyping system that deposits water-soluble supports.CAE Moves

Onto the Web

CAE flow simulation is now available on the Internet for a modest per-job fee. You purchase no software, and you need only a PC with a Web browser. Moldflow Corp., Lexington, Mass., offers this capability via a new website, www.plasticszone.com. It offers a number of features, including a materials calculator to help in resin selection and CostCruncher, a free mold-quotation calculator.

Most important, however, is iMPA, an internet-enabled version of Moldflow’s Part Advisor, which is a quick and easy, Windows-based simulation program that answers questions about moldability early in the design process.

To use iMPA, you go to the plasticszone site and download the 6-MB iMPA software file (or you can install it from a CD). Then you open an STL version of a CAD solid model of your part, select a material from the Moldflow database, and enter the process conditions and gate location. From this, iMPA creates a “digital fingerprint” of your model and registers it on Moldflow’s website. This fingerprint is only a small identifying signature of the model, not the complete model itself. Thus, your model never leaves your computer, maintaining security and avoiding the need to transmit large files over the web.

Once you pay on-line via credit card, an authorization key is sent back to your computer to allow the simulation to run on your desktop. It typically takes 20-30 min. You can run simulations as often as you like, without time limit, for no additional fee. You can try out different materials, gate geometries, and process conditions. But you can’t change the model geometry at all without paying a new fee of $49.95. After the current introductory period, it will go up to $349.95. Whereas iMPA is aimed at the occasional user, frequent users can purchase Part Advisor for $7000.

New Twist on Runner Balancing

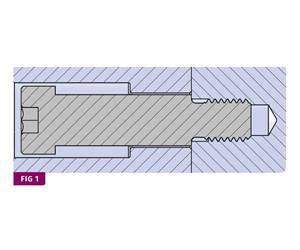

In October, Beamont Runner Technologies, Inc., Erie, Pa., plans to come out with RunnerFlow 3D software. It will apply company founder John Beaumont’s patented MeltFlipper concept to 3D computer-aided runner balancing. What’s different from other CAE flow-simulation programs for injection molding, is that the MeltFlipper is designed to fix shear-induced flow imbalances that occur frequently in geometrically balanced runner systems. According to Beaumont, the MeltFlipper disrupts the natural tendency for branched runners to distribute hotter and cooler melt of different viscosities to different cavities by introducing 90° turns in a plane different from that of the runner branches. With the MeltFlipper, you can double or quadruple the number of cavities without sacrificing product consistency, Beaumont says. He notes that using the MeltFlipper to control temperature and viscosity differences throughout the runner system also helps control gas flow in gas-assist molding.

RunnerFlow 3D will be available for license and will also be accessible to registered users via Web browser. Users will be able to enter hot- or cold-runner geometry through simple menu picks (number of cavities, layout type, runner length and diam.) or by downloading CAD geometry. The software will analyze and display shear, temperature, and viscosity variations created between runner branches. For users that also license the MeltFlipper technology, the program will automatically provide the appropriate MeltFlipper design details required to optimize balanced flow.

Calculate Cooling Times

MoldCool Estimator for Windows is a new software program from CAE Services Corp., Batavia, Ill. It is said to be an easy-to-use method of calculating cooling times for injection molded parts. You select from a menu the type of resin and mold steel, then enter the nominal and maximum part thickness, size of cooling channel, and nominal distance of the channel from the part. Within seconds, the program calculates cooling time. MoldCool Estimator costs only $600 but is said to be accurate within 2-3%.

A new feature of MCBase 4.2, the latest version of the CAMPUS merge program, is a virtually instantaneous calculation of cooling time. MCBase 4.2 was developed in Germany and is available here from The Madison Group, Madison, Wis. It permits combining into one database single-point and multi-point property data on 5700 materials from more than 50 resin companies that belong to the CAMPUS consortium. The new Cooltool calculator automatically selects CAMPUS data on thermal properties for the user’s choice of resin. The user then enters the melt and mold temperatures, ejection temperature, and nominal wall thickness. In just a second or two, the program provides an overall cooling time and graphs of average part temperature vs. time and time/temperature profiles at different points through the thickness of the part. Multi-plant firms can distribute this capability over an extranet as part of the new Web MCBase option.

Flow Simulation Upgraded

A new release of C-Mold 2000 injection molding simulation software from Moldflow Corp., Lexington, Mass., includes two major upgrades. One is called Fusion, the ability to work directly from a CAD 3-D solid model of the part. This eliminates the time-consuming task of creating a midplane model for analysis. This capability in new C-Mold 2000.7 is similar to that in Moldflow’s flagship Plastics Insight product. Another enhancement in C-Mold 2000.7 is a thermoset underfill encapsulation module to simulate the increasingly popular “flip-chip” microchip encapsulation process.

New CAD Package for Mold Design

VX Vision Mold Edition is a new, full-featured, Windows NT mold-design package available for only $4000 from Varimetrix Corp., Palm Bay, Fla. Designed for injection, compression, and blow molds, it lets designers use both surface and solids modeling within the same modeling task and then blend the two together. Other features include the following:

- One-click conversion of a solid part model into a cavity.

- Automatic application of resin-shrinkage factors for cavity/core sizing.

- Automatic core and cavity separation.

- Generation of parting lines, parting surfaces, shutoffs, slides, and inserts.

- Automatic definition of mold-plate envelope from an open surface set.

- Automatic mold-base design with D-M-E mold-base and component library.

- Automatic mold assembly from a solid model.

- IGES and STEP translators with surface healing.

- NC programming and verification.

Add Art to Your Molds

New Release 4.5 of ArtCAM software from Delcam Inc., Windsor, Ont., helps design low-relief artwork that appears to be engraved or embossed on the surface of a plastic part. ArtCAM V. 4.5 helps moldmakers transfer artwork to a mold surface, translating the gray scale of an image into different levels of relief. Also new is ability to wrap the artwork around the 3-D surface of a part. ArtCAM costs $7500.

Analyze Coex Die Flow

Newly enhanced software can help extrusion die designers optimize flow geometry or help processors predict performance of their dies with new resins or process conditions. Compuplast Canada Inc., Mississauga, Ont., has released Version 5.0 of its Flow 2000 Windows-based software for modeling flow in extrusion dies. New features include ability to model flat-die coextrusion of up to five layers. (Future enhancements will extend this ability to pipe, tubing, and blown-film dies.) The software displays a graph of velocity profile throughout the melt stream and numerical values of velocity, shear stress, residence time, and pressure drop.

Also new is a set of templates that creates a 2-D grid (or mesh) for analysis almost instantly rather than taking several hours. Processors can now be supplied with a preset geometry template of their dies, so that all they need to do is enter the resin type and process conditions in order to predict die performance. The 2-D software costs $15,000 and templates could cost from $500 to $1500. Compuplast also offers a new 3-D flow module for very detailed analyses, but 3-D calculations can take hours to run.

Wash Away Supports From Rapid Prototypes

The newest enhancement of the fused-deposition modeling (FDM) system of rapid prototyping deposits a water-soluble support material that can be simply washed away in an ultrasonic cleaning device. Called WaterWorks, this new capability from Stratasys, Inc., Eden Prairie, Minn., even permits making models with moving parts. FDM involves extruding ultrafine layers of thermoplastic to build up a model.

Related Content

Why Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)