CertainTeed Cuts No Corners Toward Sustainable Certainty

On Site

At this building-products powerhouse, the commitment to sustainability runs deep and extends to virtually every aspect of its business.

To say sustainability is serious business at CertainTeed Corp. would be selling this processor of PVC (and non-plastic) buildingproducts short. Yes, they have charging stations for electric cars in the parking lot at their Valley Forge, Pa., headquarters. But at CertainTeed , the commitment to sustainability runs deep and extends to virtually every aspect of its business, from the way the company designs products to how it makes them, how it recycles them, and even how its employees discard their trash.

CertainTeed was founded in 1904 as General Roofing Manufacturing Co. More than 100 years later, it ranks as one of the world’s largest building-products companies. A division of Saint-Gobain in France, CertainTeed employs more than 6000 in over 65 manufacturing facilities throughout the U.S. and Canada. Its annual sales exceed $3 billion.

Most people connect sustainability and plastics closely with the packaging market. That’s not surprising, considering the high visibility of bottles and other containers. But sustainability is a huge issue in the building and construction market as well. According to the United States Green Building Council (USGBC), buildings in the U.S. “are responsible for 39% of CO2 emissions, 40% of energy consumption, and 13% of water consumption per year.”

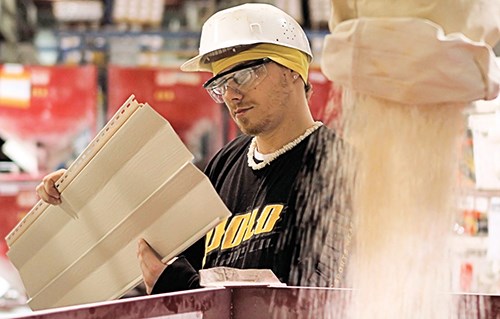

CertainTeed’s vinyl-siding products are produced in four plants throughout North America, notes Brian Kirn, marketing manager of CertainTeed Siding. One facility in Social Circle, N.C., is devoted to cellular PVC products. Another plant in Buffalo, N.Y., makes fences, rails, and decking. The company would not divulge its equipment capacity, except to point out that extrusion and injection molding are performed at all of these locations.

The company has approached sustainability from virtually every conceivable angle:

•It reinforces sustainability at the very core of its corporate culture to include employee training and outreach.

•It started what it calls “Lunch and Learn” training sessions, aimed at teaching builders and architects about the sustainable built environment.

•With Saint-Gobain, it has implemented a Sustainable Product Development (SPD) program to ensure that the impact of its products’ life cycles are considered throughout the product development process.

•It has achieved third-party certification on a per plant, per product basis for its products’ sustainable attributes.

As a result of these and other efforts, the company has reduced its energy, water, waste, and carbon footprint over the past three years. In 2012 Saint-Gobain/CertainTeed ranked fifth in the Industrials sector of the Carbon Disclosure Leadership Index (CDLI).

The CDLI is a measurement created by the Carbon Disclosure Project (CDP), an independent, not-for-profit organization that promotes reducing greenhouse gas emissions and sustainable water use. The disclosure score is based on a 100-point scale, and last year Saint-Gobain/CertainTeed received a score of 95. The company’s score improved from 89 in 2010 to 94 in 2011. Also, Saint-Gobain/CertainTeed has achieved the Energy Star Sustained Excellence Award for the past three years, attesting to its continued success in mitigating the environmental impacts of its operations.

CORE COMPETENCY

Sustainability at CertainTeed begins well before any plastic is processed. In 2006, the company launched its SPD, which starts at the R&D phase. “Environmental responsibility is a core competency at CertainTeed,” Kirn explains. In the SPD process, the sustainability of a product’s supply chain is evaluated, raw materials are sourced from recycled or renewable materials, and closed-loop design is considered.

At CertainTeed, SPD focuses on life-cycle thinking and product stewardship; incorporation of recycled content and biobased materials; sourcing regionally; supporting local economies; low VOC emissions, focusing on human health; transparency concerning product sustainability; avoidance of chemicals of concern; and assessment of the sustainable supply chain.

For all vinyl products, a life-cycle assessment (LCA) is performed to fully understand and minimize the impacts of a product. LCA is a method for identifying and quantifying the environmental impacts of a product from cradle to grave—including emissions to air, land, and water as well as consumption of energy and other material resources. During the SPD process, energy, water, waste, and transportation are evaluated to reduce any potential impacts during production and manufacturing. The feasibility of a take-back, or recycling, program for a product’s end-of-life is also examined.

For example, CertainTeed Siding in 2011 completed a life-cycle assessment on its CedarBoards D6 line of insulated vinyl siding to understand the environmental impacts associated with this product, which until then was made almost entirely of virgin material. CertainTeed Siding assessed the results and through sustainable product development moved to integrate recycled material. Now, the product line contains at least 53% post-consumer and industrial scrap. The results of this effort were lower environmental impact in five categories: Global warming potential was cut by 33%; acidification by 36%; eutrophication 22%; ozone depletion 63%; and smog 13%.

The analysis was conducted by Green Circle Certified, LLC, Royersford, Pa., with which, along with sister company Sustainable Solutions Corp., CertainTeed has been working for the past decade. States Kirn, “GreenCircle has the expertise to evaluate LCAs and subsequent improvements to the life-cycle impacts of our products. Life-cycle data is one of the most trusted sources for determining the environmental performance of products. GreenCircle certification adds another level of integrity to our LCA claims.”

CertainTeed supported the development of recycled-content products to launch what it calls its Siding Take Back Program. The company has established a network of nearly 300 distributors and contractors that supply it with scrap from new vinyl siding installations, along with the old material that was removed. CertainTeed uses a third party to clean and reprocess this material.

Kirn adds that CertainTeed was the first siding manufacturer to submit its LCA to the Building for Economic and Environmental Sustainability (BEES) program, which allows comparison of building products on a life-cycle basis. BEES fully reviews and investigates each product LCA to ensure that data is correct and accurate.

SUSTAINABLE TRAINING

In-house training is also a key component of CertainTeed’s sustainable efforts. Since 2010, the company has trained more than 6000 employees in sustainable manufacturing and operations and general sustainability. As a result of this effort, CertainTeed has seen significant improvements at the plant level: Overall energy consumption is down 15%, water usage down 21%, and waste generation down 29%.

This effort has trickled down to other areas. In the Social Circle, Ga., plant that makes cellular PVC trim, CertainTeed has been able to divert in excess of 200 tons of material from landfill by implementing an advanced segregated recycling program. This includes not only efforts to minimize waste throughout operations and recycle manufacturing scrap, but extends to employee beverage bottles, cans, paper, and packaging materials.

Sustainability is a moving target and, as Kirn puts it, CertainTeed “has been ahead of the curve and will continue to focus on being a step ahead” of the competition. Its long-term sustainability goals include:

•Extending sustainability initiatives throughout its supply chain and logistics.

•Ongoing reduction of carbon footprint through continuous improvement of energy efficiency, as well as the evaluation and utilization of renewable energy sources where feasible.

•Accelerating sustainable product development and continuing to understand product life-cycle impacts.

•Establishing closed-loop recycling systems for as many products as technically and economically feasible.

•Driving safety culture towards zero injuries and increasing safety awareness in all manufacturing operations.

•Continuing to support local economies.

•Improving the sustainability of the packaging of all products

•Leading industry in energy, water, and waste reduction

•Conducting LCAs and publishing Environmental Product Declarations for all products where feasible.

Related Content

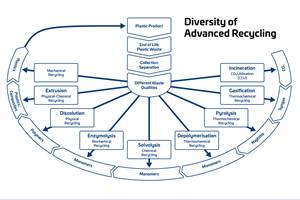

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreRecycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)