Cleaning Molds, Part III Ultrasonics Make Life Easier

Is there a “perfect” cleaning system for molds and tooling that would allow a significant reduction in labor hours and tooling damage while providing consistent cleaning results?

Is there a “perfect” cleaning system for molds and tooling that would allow a significant reduction in labor hours and tooling damage while providing consistent cleaning results? If it exists, it would meet these 10 criteria:

- Repair technicians would like using it.

- It would be totally non-abrasive to all types and hardnesses of steels, platings, coatings, and polishes.

- It would not require a repair technician to manually control or babysit the process.

- It would not pose a safety hazard to man, machine, or the surrounding area.

- It would be user-friendly and environmentally friendly.

- The cleaning unit itself would be easy to clean and maintain.

- It would not be loud or irritating.

- It would have the ability to clean subassemblies and tooling retained in plates.

- It would remove 90% of mold fouling.

- It would not leave behind any type of residue or film on tooling or plates or contaminate the area with dust or grit.

One cleaning method that comes close to meeting all of the above requirements is ultrasonic immersion cleaning. Nothing has more impact on reducing cleaning time, improving mold-cleaning consistency, and reducing tooling damage than this non-abrasive, user-friendly method.

How does it work?

Ultrasonic cleaning uses high-frequency sound waves to remove mold residues and fouling from tooling and plates that are immersed in a heated (usually 160 to 180 F) aqueous solution. An ultrasonic generator converts standard line-frequency current (60 or 50 Hz) into high-frequency electrical energy (20,000 Hz or more). The generator is connected to small transducers that are mounted to the bottom or sides of a wash tank. These transducers vibrate at ultrasonic frequencies (20 kHz and above) when the current passes through. This causes the bottom or sides of the tank to vibrate like the diaphragm in a speaker, which creates microscopic bubbles that form and collapse in the tank (a phenomenon known as cavitation), which scrub and loosen vent residues and grime. The energy released from these microscopic scrubbing bubbles produces forces at 10,000 F at 7500 psi, which is powerful enough to loosen contaminants without damaging critical edges or surface finishes.

The cleaning ability of ultrasonics depends on several key factors:

- Cleaning solution: The type of detergent required is dependent upon the process and type of resin you run, which leaves behind specific types of off-gassing residue. Highly alkaline solutions such as sodium hydroxide do the best job of removing stubborn contaminants, light rust, and heavy grease on most tooling and plates, with no harm to most platings and coatings. On the downside it can be caustic, posing a potential health risk, and may require neutralization before disposal, depending upon local codes.

Mild alkaline solutions also are available that perform well on many residues without the caustic issues. But in general, the friendlier the detergent, the less effective it will be on stubborn contaminants.

Slightly acidic solutions, such as those containing low concentrations of citric acid, excel at rust and oxide removal, but must be used with caution on some tool steels because they can react with the iron in the steel, turning it gray. This normally does not cause a technical problem but doesn’t sit well with toolmakers.

There also are several environmentally safe detergents being used that do a fair job of removing most contaminants left from resins in use today. Combined with a minimal amount of hand scrubbing on heavily contaminated areas, these user-friendly solutions are gaining popularity with companies simply because of their ease of disposal, less mess, and safer working conditions.

- Ultrasonic power and frequency: Cleaning heavy mold plates and tooling requires use of heavy-duty equipment and not your typical ultrasonic jewelry cleaner. The amount of power (wattage) needed depends on the tank size and the type of load to be cleaned. For a tank of 70 gal (approx. 30 x 30 x 30 in.), 3000 watts at 30 kHz performs well.

The higher the frequency rating, the less aggressive the cleaning power. Common systems use either 40 or 30 kHz and a few use 25 or 20 kHz. Thirty kHz is a good compromise between cleaning ability and noise level. Lower frequencies can be extremely loud and irritating.

- Transducer type and construction: The heart of the ultrasonic system, transducers come in two types: (1) magnetostrictive and (2) piezoelectric. Magnetostrictive transducers are typically more rugged and create the most aggressive cavitation action.

The best transducers also are zero-spaced and silver-brazed to the tank rather than bolted or epoxy-glued, because the latter have more tendency to fail slowly over time. Transducers may be placed at specific locations in the tank to correlate with the size and configuration of plates being cleaned.

- Tank design and construction: Buy a tank large enough to fully immerse your largest mold plates. You will regret saving a few bucks to get a small tank that will require you to flip the mold plates over for complete cleaning. Also make sure the tank is constructed of at least 12-gauge stainless steel and be sure to have the manufacturer weld a few support bars across the bottom to keep plates and tooling baskets from resting directly on the bottom of the tank.

Purchase or build a hinged cover for the top of the wash tank to slow down the evaporation of 180º F water. Also fabricate a tall (about 4 ft) stainless backsplash shield that will run the length of your system and will keep your walls clean and direct any runoff back into the tanks.

When you fabricate or purchase tooling baskets, be sure the handles are tall enough to extend above the surface of the hot cleaning solution and incorporate an eyehook to lift with an overhead chain hoist. Design the baskets to fit side by side across the bottom and make sure the basket material perforations are 0.25 in. or larger so cavitation is not impeded.

Buying considerations

In the real world, mold plates will get slammed into the sides of the wash tank and baskets full of tooling will be dropped in too fast. Exposed knobs will be ripped off. The tank will run 24/7 because everyone will suddenly have something that needs to be ultrasonically cleaned, as will be evident by the grass clippings and paint residue floating on the surface of the wash tank. And, due to the nature of ultrasonic operations—high heat and constant vibration, the system’s parts can shake loose, wear through, and burn out.

Heavy-duty, bullet-proof, robust, and solid are the words to keep in mind when shopping for an ultrasonic cleaning system that will perform reliably in a busy mold-repair shop. Unless absolutely necessary, stay away from bells and whistles such as automatic loaders, conveyors, dryers, and fancy cabinetry.

However, do make sure of the following:

- The transducers are warranted for the life of the system.

- The tank is warranted for 20 years or more against cavitation wear-through, which can cut transducer life drastically.

- The wash tank has a pump filtering system and is easily accessible.

- The pump intake is screened to keep small dowels, o-rings etc. from damaging the pump impeller.

- The tank drain valves are easily accessible.

- There are no protruding knobs, handles, switches, or buttons on the console.

- Tank heaters are easily accessible.

Try it out

To see if ultrasonics will work for you, send samples of contaminated tooling to an ultrasonic equipment supplier as a test. This also will help the supplier match your specific contaminants with the proper detergent for efficient removal. Some suppliers will even let you use a trial unit.

Once the system is installed, you will see an immediate reduction of labor hours simply because of the speed with which tooling will be cleaned compared with laborious hand cleaning of one piece at a time. As a bonus, there will be no more rounded-over edges or scrubbed-off platings and coatings.

Steven Johnson worked as a toolmaker for 26 years, rebuilding and repairing multicavity molds for Calmar Inc. and then as mold-maintenance engineer for Hospira Inc., a medical device manufacturer. Today, he is the maintenance systems manager for Progressive Components and has his own business, MoldTrax in Ashland, Ohio, which designs and sells software for managing mold maintenance (www.moldtrax.com). He can be reached at steve@moldtrax.com or (419) 289-0281.

Related Content

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreHot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

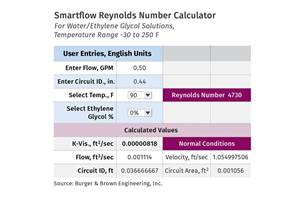

Read MoreCooling Geometry and the Reynolds Calculation

The original Turbulent Flow Rate Calculator worked well with a round circuit diameter, such as a drilled passage, but not as well using hydraulic diameters. Here’s how the problem was fixed.

Read MoreRead Next

Cleaning Molds: Part I

Cleaning a mold is a critical part of the repair process, but many myths must be dispelled.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=300;quality=90)