‘Collaborative’ Robot Works Alongside Human Workers

The goal of Baxter's builder is to make U.S. manufacturing more globally competitive by making automation more affordable and easier to implement.

The company name says a lot about its products. Rethink Robotics is a five-year-old, Boston-based company that makes what it calls “a different kind of robot.” The device has a deliberately anthropomorphic look, with two multi-joined arms on a columnar “body,” an expressive pair of humanoid eyes, and a friendly-sounding name, Baxter. All of this might sound a bit cutesy to a no-nonsense process engineer, but Baxter is designed with a serious purpose in mind.

The goal is to make U.S. manufacturing more globally competitive by making automation more affordable and easier to implement, so that valuable employees can be freed from simple repetitive tasks and devoted to more value-added jobs. Baxter is not for high speed and precision, but for repetitive pick-and-place tasks that don’t require expensive human labor.

Baxter is designed to be implemented quickly and easily with no programming skills, to work safely beside human workers, to communicate with them in a simple and intuitive fashion, to be self-guided by means of built-in sensors, and on top of all that, to have a relatively low price point.

Safety is one of the key principles of Baxter’s design. It incorporates 360° sonar and a front-facing vision system to detect human presence and also to perform its tasks. It can “see” in 3D, sensing height and distance. With vision, it can detect objects on a conveyor, for example, and count parts as it packs them into containers. Baxter’s “servo-elastic” control prevents harmful collisions: If one of its arms meets resistance force of less than 1 lb, it will stop—and then continue on its path when the resistance is removed.

Simplicity is another key principle. Baxter is a complete system of hardware, software, controls, user interface, safety, and sensors; it needs no integration. Take it out of the box, and Baxter can be trained and working in under an hour, the company says.

Baxter “learns” tasks by lead-through teach programming: With very light pressure, a worker guides its arms through the desired motions and presses a button to actuate the grippers at the desired positions. Each arm has seven servo-driven axes. The unit is powered by 120V.

Rethink Robotics describes Baxter as a “collaborative robot.” Baxter’s “face” is a small LCD screen with two eyes depicted on it. Those eyes follow the task the robot is currently focused on. They have several different expressions intended to help workers understand Baxter’s “state of mind,” so to speak. For instance, a confused look, with raised eyebrows, signals a problem, and the eyes turn to the arm that needs attention.

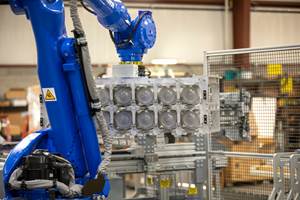

The Rodon Group, a large custom and proprietary injection molder in Hatfield, Pa., is one of the first plastics companies to employ Baxter. It uses the robot to pick parts off a conveyor and pack them into a box in layers—just the sort of task Baxter was designed for. Lowell Allen, Rodon’s sr. v.p. of manufacturing, is happy with Baxter’s performance and expects to get more like him. “Conventional robots require guarding because they can be dangerous,” Allen says, “but Baxter is designed to work alongside people without need for protective guarding.” He also likes that Baxter can be taught jobs by ordinary line workers with no programming knowledge. The “collaborative” aspect is useful, too: Baxter’s semblance of a face “makes it easier for workers to accept,” Allen says.

Related Content

An Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More