Could your RFQ process be jeopardized by a retirement?

The moldmaking industry has lately lamented its talent depletion by demographic shift, as aging toolmakers step away from their benches for the last time, primarily focusing on the shopfloor and steel-cutting implications, but what about the front office and quoting?

“At these tool shops, you’ve got guys that have been quoting tools for 20, 30, 40 years,” says Rick Burke, VP of marketing at aPriori, Concord, Mass. “They’ve been doing it for so long, they just kind of know what a mold will cost.”

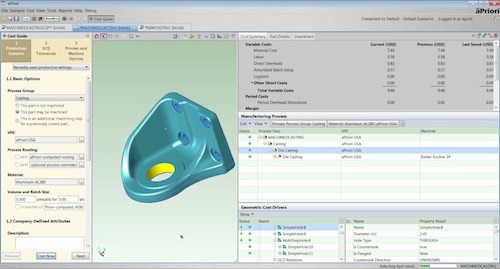

aPriori is a supplier of product cost-management programs (read more here)—software that uses a few key inputs to fulfill a request for quote (RFQ) on anything from machined metal components to single-cavity injection molds to molded parts. Customers include Ford Motor Co. and some of its tooling suppliers, like Roush Enterprises, with both parties hoping software can fill the void left when decades of mold-quoting know how trades calipers for a fishing rod.

“These guys, they’re retiring in droves,” Burke explains. “So you’ve got this weird demographic thing going on where one person has all this info in his head, or, maybe, he put it in a spreadsheet.”

How does your shop quote molds (or molded components); and would that whole process be jeopardized by a retirement announcement? If so, can a suite of software step in for decades of experience that can glance a part design and instantly start tallying slides and undercuts while determining manufacturability?

aPriori, as might be expected, is positioning itself to bridge that gap, while at the same time boosting RFQ productivity, efficiency and consistency. “Quoting is really more of an art than a science,” Burke says. “So we come along and show it can actually be a science, and we do that not to replace people but make them more productive. Guys who did 10 quotes/month, now they can do 20.”

There has been a lot of talk about the yawning skills gap facing industry, particularly moldmaking, but what about the knowledge gap? What is your shop doing to address either/both?

Related Content

-

How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

-

How to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

-

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

.png;maxWidth=300;quality=90)