Dimensional Stability After Molding: Part 4

In the first three parts of this series we focused on those influences that cause molded parts to get smaller. But there are environmental factors that also cause parts to increase in size over time.

Up to this point our discussion of dimensional stability has focused on those influences that cause parts to get smaller. But there are environmental factors that also cause parts to increase in size over time. The best example of this is the dimensional growth that occurs when parts molded in nylon absorb moisture from the atmosphere.

Many polymers are hygroscopic; they absorb water. Since water vapor is always present in the atmosphere, this is the usual source of the water that becomes absorbed into the polymer. Most hygroscopic materials under normal atmospheric conditions can absorb 0.1-0.2% water over an extended period. But nylon, because it contains hydrogen bonding, attracts water to a much greater degree. At room temperature in a “normal” environment where the relative humidity is in the range of 35-65%, the equilibrium moisture content for an unfilled nylon will hover around 1.5-2% by weight. If continually immersed this can increase to 5-8%.

This level of moisture absorption changes the mechanical properties of the polymer. Many designers and engineers complain that nylon parts lack toughness in the cold, dry winter months when indoor humidity levels can drop to 5-10%, and this is why many processors will purposely condition their nylon parts as they are being molded. It simply shortens the time frame required for the part to reach equilibrium from weeks or even months to a couple of days.

Moisture absorption begins the moment the part leaves the mold. As molded, the moisture content of the part is approximately equal to that of the pellets that went into the press. Since we assume that all nylon is properly dried before molding, this would place the moisture content for a part produced from unfilled nylon below 0.20% or 2000 ppm. This is what we refer to as dry-as-molded. From that point, the process of going from 0.2% to 2.0% starts.

Water is a plasticizer for nylon. This means it reduces the material’s glass-transition temperature. For workhorse polymers nylon 6 and nylon 6/6, this takes the glass transition from 65-70 C down to about 10 C. Water has the same hydrogen bonding as nylon; when water enters a nylon part it has the same opportunity to become loosely attached to the nylon chain as does another nylon chain.

When the water molecule becomes positioned in this way, it forces the spacing between the polymer chains to increase. The greater the amount of moisture absorption the greater the volumetric expansion. Someone measuring parts will view this as an increase in the size of the part. Typically the increase in size can equal 0.5-0.6% in an unfilled nylon 6 or nylon 6/6 if the exposure occurs at room temperature. If the temperature increases, the moisture absorption levels will increase and the corresponding dimensional changes will become larger. Fillers and reinforcements will reduce this dimensional change, however even a highly filled nylon molded under optimal conditions will still expand by approximately 0.1% or 0.001 in. for every inch of part dimension. This makes it important that the processor and the end user define the conditions under which parts are to be measured for first-article approval.

While nylon represents the extreme where moisture absorption is involved, the vast majority of polymers absorb water at some level. Materials such as polyethersulfone and polyetherimide can absorb as much as 2% by weight over time. However, because these polymers are amorphous and have extremely high glass-transition temperatures, the effect of this moisture absorption on dimensions and properties is much smaller than it is in nylon. But as the environment becomes more severe, even materials that are normally considered to be very dimensionally stable in moisture-laden environments can produce surprising responses, particularly in situations where close tolerances must be held in assemblies.

Acetal is often considered as an alternative to nylon that avoids the difficulties associated with moisture absorption. The fact that acetal is rarely dried prior to processing reinforces this notion that moisture uptake is not a concern. At room temperature and 50% relative humidity an unfilled acetal will absorb only about 0.2% moisture and will expand by approximately 0.2%, effects that are much less problematic than those encountered in nylon.

But acetal is a polar polymer and is capable of taking on larger amounts of water under the right conditions. At 100% relative humidity the moisture absorption levels increase to almost 0.8% and the dimensional growth increases to 0.7%. This behavior led to a significant problem with the actuation of an acetal piston riding in the hole in a mating part. The tolerance stack up between the piston and the hole ranged from 0.004 in. to 0.010 in. on a diameter of 0.600 in. At room temperature the assembly functioned as intended.

However, validation testing involved prolonged exposure to a conditioning process at a temperature of 85 C and a relative humidity of 95%. This allowed the acetal part to absorb enough moisture allow it to grow by 0.004 in. Parts produced to the low end of the tolerance provided for enough clearance between the two parts to allow for proper operation. But if the parts were molded to the high side of the tolerance, the subsequent expansion due to moisture gain was sufficient to cause the part to bind and resist movement.

Before we end this series on dimensional stability, we will discuss a reversible effect that results from a property that all materials have: the coefficient of thermal expansion. In Part 5 in the next issue, we will cover how this property influences the results that are obtained when parts are measured in different environments.

Editor’s note: You can read the next part in the series by clicking here.

Related Content

The Effects of Temperature

The polymers we work with follow the same principles as the body: the hotter the environment becomes, the less performance we can expect.

Read MoreAre Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

Read MoreUnderstanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

Read MoreThe Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

Read MoreRead Next

Dimensional Stability After Molding—Part 2

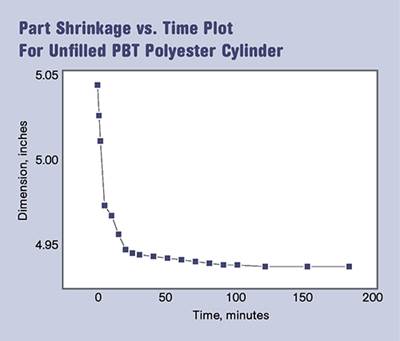

After molding, acetal parts can continue to shrink at room temperature and even in the cold.

Read MoreDimensional Stability After Molding: Part 1

The degree to which molded parts shrink as they cool is largely dependent upon the composition of the material being processed.

Read MoreDimensional Stability after Molding—Part 3

Any process that involves melting and re-solidifying a polymer involves a compromise between achieving the perfect structure and producing a part that can be sold at a price that the market is willing to pay.

Read More.jpg;width=70;height=70;mode=crop)