End Market Reports

Market Outlook: Motor Vehicles; Market Outlook: Aerospace Products and Parts

Market Outlook: Motor Vehicles

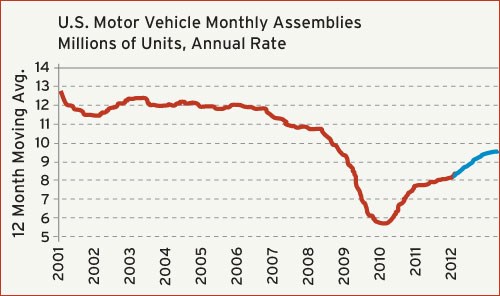

The total number of motor vehicles assembled in the U.S. registered a solid increase for the second consecutive year in 2011. After hitting a record-low level of only 5.7 million units in 2009, the number of assemblies in 2010 jumped 35% to 7.7 million units. In 2011, the number of assemblies escalated to 8.5 million units, which was a gain of 10%. Our forecast calls for another gain of 10% in 2012, and this would push the annual assemblies total to 9.5 million units.

Under normal circumstances, nobody would complain about a third straight year of double-digit growth, especially given the prevailing economic environment in the U.S. But as the accompanying chart illustrates, the U.S. motor vehicle industry is far from where it was prior to the last recession, and it will take several more years of growth in excess of 10% per annum to get us back to those levels. And as a wise man once said, “Who cares if the glass is half-full or half-empty … just fill it up.”

The average age of a car in America is 11 years. The value of the U.S. dollar is relatively low compared to the currencies of our major trading partners, and the price of gasoline is relatively high and rising. These are all strong reasons to expect solid growth in the global market demand for domestically-produced, fuel-efficient autos in the coming years. Unfortunately, the positive factors are mitigated by a high unemployment rate, slow income growth, low confidence, and increasing uncertainty amongst American consumers. So the activity levels for the U.S. auto industry will continue to rise at, at best, a moderate rate for the foreseeable future.

Market Outlook: Aerospace Products and Parts

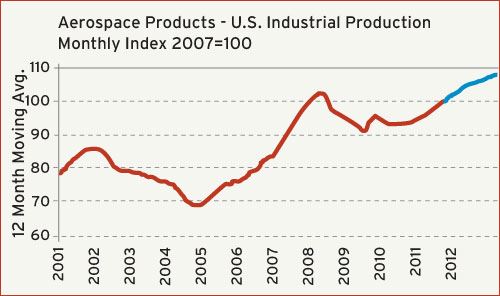

After a modest decline of just under 2% in 2010, total U.S. output of aerospace products escalated by a robust 8% in 2011. This industry is poised for another solid year of growth this year, and our current forecast calls for a gain of at least 6% in 2012. This sector did not suffer as badly as most others during the recession in ‘09, and the gains expected for this year will put total output above the pre-recession levels.

For the purposes of analysis, it is necessary to divide the aerospace industry into two categories: defense and non-defense. On the non-defense side, the expected increase in U.S. output is largely due to Boeing ramping up production of its new, fuel-efficient Dreamliner. The cost of jet fuel has jumped dramatically in recent years, and there is little reason to expect that this uptrend will not persist. And while there are a number of alternative fuels (electricity, propane, solar, etc.) under development that may ultimately prove viable for ground transportation, there are no new types of fuel in the pipeline for air transport. So planes must get more efficient. The good news for moldmakers is that more parts will be made from plastic and other composite materials in an effort to make planes lighter. The bad news is that this industry is so small that it is extremely difficult to enter the market if you are not already in it.

On the defense side, the fastest growing aerospace segment is un-manned aircraft (drones). These planes are cheaper to make, cheaper to operate, less dangerous to their pilots, and they are more effective at performing their tasks. The biggest knock against them is that they are maybe a little too effective, and their increased use also increases the risk of collateral damage. Nevertheless, military deployment of drones will continue to rise in the coming years. And sometime in the not-too-distant future, we can expect a sharp rise in civilian use of drones, particularly for law enforcement.

Related Content

Molder Repairs Platen Holes with Threaded Inserts

Automotive molder ITW Deltar Fasteners found new life for the battered bolt holes on its machine platens with a solution that’s designed to last.

Read MorePEEK for Monolayer E-Motor Magnet Wire Insulation

Solvay’s KetaSpire KT-857 PEEK extrusion compound eliminates adhesion and sustainability constraints of conventional PEEK or enamel insulation processes.

Read MoreDesign Optimization Software Finds Weight-Saving Solutions Outside the Traditional Realm

Resin supplier Celanese turned to startup Rafinex and its Möbius software to optimize the design for an engine bracket, ultimately reducing weight by 25% while maintaining mechanical performance and function.

Read MoreHonda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)