Engineering Thermoplastic Processes Like a Thermoset

The first quarter of 2005 will see the first commercial production of a dramatically new family of resins that offer the processing advantages of liquid thermosets plus the properties and recyclability of engineering thermoplastics.

The first quarter of 2005 will see the first commercial production of a dramatically new family of resins that offer the processing advantages of liquid thermosets plus the properties and recyclability of engineering thermoplastics. Cyclics Corp., a company formed in 1999 to acquire patented technology developed by General Electric Co., is about to open a 5.5-million-lb/yr plant to produce its first CBT resins. These low-molecular-weight PBT oligomers are solids that melt at relatively low temperatures to yield a water-like viscosity that readily impregnates fiber reinforcements or accepts high loadings of fillers. Upon further heating, the liquid polymerizes into a normal PBT polyester.

This new type of material leaps previous hurdles to high-performance thermoplastic composites and also has broad potential in rotomolding, casting, injection molding, and powder coatings. For example, CBT resin has been demonstrated in “thermoplastic RTM” molding, in which glass mat or fabric reinforcements were impregnated by drawing the liquid resin through the mold using vacuum alone. Impregnation is said to be easier than with epoxy. A hockey stick containing more than 75% carbon fiber has been impregnated with CBT. In addition, continuous-fiber prepregs can be made with CBT by melting, impregnation, and cooling again to a solid without curing. CBT can also be compounded without curing at low temperatures with pigments or other additives to make masterbatches for use in thermoplastics. Also, company sources report that low-viscosity CBT resins show advantages in preparing nanocomposite compounds, because the CBT resins facilitate exfoliation (delamination) of the nanoclay particles.

Gearing up for growth

Cyclics’ first commercial plant is located on the grounds of a BASF facility in Schwartzheide, Germany. Cyclics will take standard PBT resin produced by BASF there and partially depolymerize it into lower-MW CBT resin. Cyclics says half its plant capacity is already committed to certain customers, so the company is planning to double its capacity to 11 million lb this year. The company is also searching for a location for a world-scale plant of 55 million to 110 million lb that could be up and running as early as 2009.

In high volumes, CBT resins will cost around $6/lb initially. However, once the world-scale plant is operating, prices should be very close to that of standard PBT.

Cyclics has concluded a number of agreements with partners in application development. For example, Dow Automotive has a long-term exclusive right to develop five areas of car, truck, bus, and rail applications. Dow is said to be interested in developing injection molding, RTM, and SMC applications in areas like body panels, truck boxes, load floors, and bumper beams.

Meanwhile, Alcan Composites, a unit of Alcan Inc., has exclusive rights to develop architectural, display, and graphic-arts markets, as well as general industry infrastructure applications—such as car bon-fiber tapes for reinforcing bridges. Gaoth Tec Teo of Galway, Ireland, is working with Cyclics and Mitsubishi Heavy Industries of Nagasaki, Japan, to develop composite wind-turbine blades. These blades are expected to use epoxy prepregs co-laminated on top of CBT prepregs. Cyclics also has an R&D agreement with Ahlstrom Glassfibre Oy of Helsinki, Finland, to develop wind-turbine and marine applications using Ahlstrom’s reinforcements.

In addition, Cyclics named the P-Group of Ferrara, Italy, as the sole compounder of CBT resin for the European rotomolding market. (Cyclics also recently appointed an account manager, Barry Aubrey, specifically for rotomolding.) And the first actual commercial application for CBT is a tough, heat-resistant material for thermoforming plug assists. Called Eccolite Ultra Syntactic Foam, it is supplied in machinable rods, blocks, and sheets—all filled with hollow microspheres—by Emerson & Cuming Composite Materials.

Two grades to start

Cyclics initially is launching two grades of PBT precursors, though its technology is applicable to other polyesters such as PCT, PTT, and polycarbonate. CBT also has potential for copolymerization with epoxy and other resins—a developmental TPE has already been prepared by reactive extrusion.

| PROPERTIES OF POLYMERIZED CBT RESIN | |

|---|---|

| Density, g/cc | 1.31 |

| Tensile Yield Str., psi | 7800 |

| Yield Elongation, % | 3.2 |

| Ultimate Elongation, % | >50 |

| Tensile Modulus, psi | 392,000 |

| Flexural Modulus, psi | 345,000 |

| Flexural Strength, psi | 10,700 |

| Notched Izod, kJ/m2 | 6.7 |

| Unnotched Izod | No Break |

| Mold Shrinkage, % Flow Direction, 0.16 in. | 1.5 |

The two initial grades are CBT 100 and CBT 200. The first is aimed at injection molding, rotomolding, compounding, nano composites, and thermoplastic masterbatches. It melts at around 180 C (356 F) and can be processed between 190 and 240 C (374 to 464 F). It has a fast-acting catalyst that cures in a few seconds to a mi nute, depending on temperature.

CBT 200 is designed for longer working times in composites, casting, and coatings. It melts at about 160 C (320 F) and is processed at 170 to 240 C (338 to 464 F). Cure times can range from a few minutes to more than an hour. Both resins have initial melt viscosities of about 10 to 40 cps over a temperature range of 170 to 220 C. Both materials yield identical PBT resins with properties at least as good as those of standard PBT (see table). Company sources note that CBT-based resins usually have twice the molecular weight of standard PBT without affecting processability. Higher MW reportedly confers advantages in weathering and wear resistance.

Both CBT grades can be supplied in one-component or two-component forms. CBT uses standard tin and titanate catalysts used to polymerize polyesters. These materials are said to present no toxic hazard to processors.

Related Content

Lanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

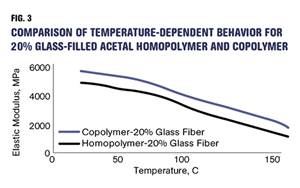

Read MoreTracing the History of Polymeric Materials: Acetal

The road from discovery in the lab to commercial viability can be long, and this was certainly the case for acetal polymers.

Read MoreHow Do You Like Your Acetal: Homopolymer or Copolymer?

Acetal materials have been a commercial option for more than 50 years.

Read MoreWhat's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More