Enterprise Software Solution Smooths Custom Extruder’s Growth

On Site: Custom Profile

Sometimes an operation can grow too quickly, even beyond its ability to manage the new business. Custom Profile solved this problem by replacing off-the-shelf and home-made enterprise software with one comprehensive package.

While every processor wants to expand, sometimes an operation can grow too quickly, even beyond its ability to manage the new business. Custom Profile, headquartered in Grand Rapids, Mich., was in such a position some years back. The company solved that problem by replacing its hodge-podge of off-the-shelf and home-made enterprise software with one comprehensive package.

The profile extruder was founded in 1992. Like many plastics stories, this one has a humble beginning, with one employee, one extrusion line, and a modest 3000 ft² facility. Today, the firm employs more than 150 people and runs around the clock five days a week, relying on 14 single-screw extrusion lines in a 115,000 ft² plant. It also has four extrusion lines in a 39,000 ft² plant in Juarez, Mexico, opened in 2008.

For about 18 months, Custom Profile has been part of Blackford Capital LLC, a Grand Rapids-based private-equity firm that focuses on investing in profitable, mid-size Michigan-based companies—and keeping them there. Custom Profile’s 2012 sales were $25 million, and it is heading for about 20% growth this year, notes Richard Sweers, director of operations. The plant runs a wide range of materials—including flexible and rigid vinyl, HIPS, ABS, low- and high-density PE, PP, TPE, TPO, and TPV. It makes most of its own tooling and supplements its extrusion activities with a range of secondary and finishing operations, some of which—like wood graining, texturing, notching, and finishing—are done in line. It serves customers primarily in appliance and furniture markets.

The processor’s goal is zero product defects and 100% on-time delivery. Says Sweers, “Last year, we shipped 49,000 line items and were late with three. So far this year we have shipped more than 27,000 and have been late with one.”

FOUR'S A CROWD

Though Custom Profile’s sales have increased in 20 of the 22 years it has been in business, growth sometimes comes with a hiccup or two. Back in 2002, the firm had just doubled the size of its existing building, and despite the economic and social uncertainty following the 9-11 attacks, Custom Profile was continuing to expand and hire new employees. But as its extrusion business developed, it became obvious to the company that its enterprise software was failing to support its needs.

At the time, Custom Profile was running its business through four different software systems, some off-the-shelf, some built in-house. This “pieced-together” combination resulted in several system crashes a day and errors from duplicated data entry, recalls Sweers. Customer service was struggling as sales orders took too long to enter due to a lack of easy access to client information. Shipping was also cumbersome and often delayed or inaccurate.

Custom Profile went on the hunt for a new enterprise software package. Its top requirements included highly configurable modules that could manage increased business transaction volume; detailed and easily configurable manufacturing Bills of Materials (BOMs) specific to the profile extrusion process; and a business management system that provided an integrated ERP (enterprise resource planning) platform with the infrastructure to support continued growth.

It used the ERP comparison tool, Soft Select, from Engleman Associates, Vancouver, Wash. (softselect.com), to establish its critical business requirements , and did extensive market research within manufacturing industries. After a seven-month evaluation process, Custom Profile winnowed its options down to two. Custom Profile employees ultimately picked the EnterpriseIQ package from IQMS, Paso Robles, Calif., because it provided structure for perpetual inventory and BOMs, gave instant access to data required to meet customer requests for information, and because IQMS had knowledgeable employees who were willing and able to support plastics processors. Custom Profile wasted no time getting started and implemented all of EnterpriseIQ’s business-critical modules in five months—on time and under budget.

“Looking in the rear-view mirror, we made the right decision,” Sweers states. “We would not be the company we are today without IQMS as a partner. The scalability of the software is phenomenal. EnterpriseIQ is a single-source solution that could be leveraged, both current and ongoing, to meet our critical business requirements.”

NEW CAPABILITIES

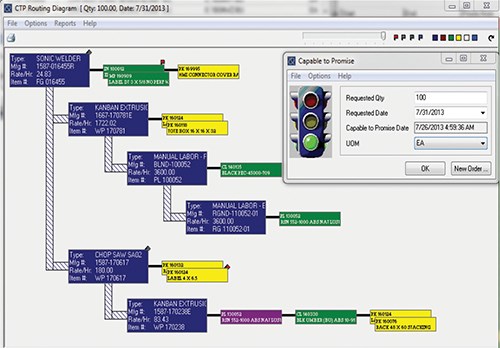

Almost immediately, Custom Profile gained the ability to service customer requirements during an initial contact with a much higher degree of accuracy. Before using the new software, Custom Profile’s sales team would typically gather the details of a job, collecting information such as quantity and date needed, and respond sometimes days later with a ship date. But with EnterpriseIQ’s robust and accurate Capable to Promise functionality embedded in the core software, Custom Profile has instant visibility of materials inventory and machine capacity, allowing representatives to give a rapid response during the initial contact, rather than at a later time.

Also included in EnterpriseIQ’s ERP core is a scheduling and material requirements planning (MRP) system. With EnterpriseIQ’s filters and drag-and-drop functionality, Custom Profile can quickly update its manufacturing schedules by work center, based on labor and tooling capacity, and create work orders from industry-specific BOMs. It can also check on-hand inventory, generate purchase orders based on MRP, and create detailed production reports, all driven by sales demand and taking into account inventory at all levels of the BOM.

“We automatically update our schedule six times a day in less than seven minutes, resulting in real-time, optimally scheduled orders effectively utilizing production time and materials,” states Sweers. “With IQMS’ lean, accurate planning tools, 80% of Custom Profile’s shipments are based on a four-day or shorter lead time.”

Within a short period, Custom Profile employees were able to focus on setup and scrap reduction projects and decrease material stock-outs based on information provided by EnterpriseIQ. As an employee-driven, continuous-improvement objective, production scrap was reduced by more than 55% over a four-year period, with annual savings in excess of $100,000.

In addition to the core ERP system, Custom Profile installed IQMS’ electronic data-interchange (EDI) solution. Unlike other ERP systems that require bolted-on, third-party programs in order to obtain increased functionality, the EnterpriseIQ system is comprehensive, requiring no cumbersome interfaces or expensive customization to access needed programs.

With the ability to automatically and seamlessly translate incoming orders directly into EnterpriseIQ Sales Orders with EDI, and to generate outgoing files and advanced shipping notices (ASNs), order-entry time and data-entry errors have been significantly reduced, according to Sweers.

Inbound and outbound EDI saves Custom Profile an estimated $35,000 a year in data-entry time. EDI also has allowed Custom Profile to carry out its goal of rapid response from quoting to delivery of product. Says Sweers, “We run EDI for one customer in the morning and then assemble and ship products the same day.”

Custom Profile also decided to implement EnterpriseIQ’s robust warehouse management system (WMS). By equipping personnel with hand-held scanners and accurately labeling inventory items with barcodes, the processor has virtually eliminated shipping errors. It reduced the labor required to ship product by one person, resulting in savings of approximately $36,000 annually.

Finally, Custom Profile invested in IQMS’ RealTime Production Monitoring system to track work-center production on some of its machines as it occurs. By communicating directly with its machines, Custom Profile receives immediate details on all aspects of production and takes control of the plant floor with improved visibility, accuracy, and accountability.

To supplement its customer-service efforts, Custom Profile has set up its system to deliver exception reports in real time so responsible employees can quickly address customer requests or requirements that fall outside the typical business process or cycle.

continuous improvement

Today, Custom Profile can see how its entire business is connected, from new program launch through order entry to product shipment. But improvement never ends at Custom Profile, notes Sweers. Custom Profile integrates new EnterpriseIQ functionality often, steadily improving the firm’s knowledge and application of the ERP system as a tool in its business processes.

Related Content

Put Some ‘Lean’ into Your Profile Extrusion Process

With everyone struggling to find talent, there are ways to reduce operator interaction with the process by applying some lean manufacturing principles.

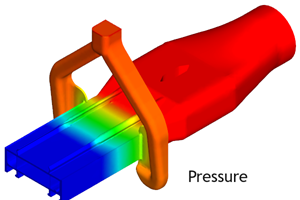

Read MoreUpdated Software Reduces Die Design Iterations

New software said to reduce the number of fine-tuning iterations and die development time by at least 50%.

Read MoreOnline X-Ray Inspection Boosts Extrusion Quality

Höhle uses Sikora’s x-ray measuring systems for inline quality control of extruded microducts.

Read MoreHow to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More