Extrusion Goes 'Just in Time' With Quick Die Changers

Two unusual new processes from Germany allow changes of profile, pipe, and pelletizing dies in just a few seconds.

Two unusual new processes from Germany allow changes of profile, pipe, and pelletizing dies in just a few seconds. One system actually mounts two dies on a sliding shuttle. The other almost instantly diverts melt flow from one stationary die to another.

The moving die changer comes from Emil Lihotzky Maschinenfabrik GmbH & Co., which is represented here by Process and Auxiliary Equipment, Ramsey, N.J. The system is based on an eight-year-old quick-change system used on pelletizing dies for detergent. The melt-flow diverter is from Trendelkamp Stahl und Maschinenbau GmbH, which has offices in Norcross, Ga. It's system uses the company's existing quick-screen-change technology.

Shuttling dies

Lihotzky introduced its patented "three-second" die changer to plastics processors at the K'98 show in Dusseldorf and has sold 20 plastics systems so far, primarily for pelletizing. In this system, two die carriers are mounted side by side on a horizontal sliding plate. One die moves out of production while the other slides into place. For profiles, this hydraulic slide plate can be coupled with quick-change calibrator sets and other downstream equipment that can be rolled into place manually. An entire profile can be changed in 5-10 min, according to the company.

Lihotzky's Twin Pelletizers come in five standard sizes for die plates of 150 to 580 mm diam., as well as custom sizes up to 1200 mm. Lihotzky's system can use a processor's existing dies by bolting them to a die-plate adapter. The transfer adapter and die plate can be heated electrically or with oil. Different specialty elastomer sealing materials are used, depending on temperature requirements.

The die changer fits any type of extruder. Bigger sizes weighing over 9 tons require a self-supporting stand. Controls can be integrated with those of the extruder or provided in a separate cabinet. The device can also be used with any type of pelletizer--hot-face, underwater, water-ring or, nitrogen-blanketed. Two quick-acting locks hold the pelletizer in place. The smallest model, PAH 40, for 40-70 mm diam. screws, costs around $76,000. Model PAH 62, for 50-70 mm screws, costs about $85,000 without pelletizer.

Divert the flow

Trendelkamp's "twin-bolt" rapid die-change system is so new it doesn't have a formal name yet. It was developed for a U.S. profile customer and first installed last year. A second profile installation is under way and is specified to accomplish 30-sec changeovers. In trials, it has changed dies in as little as 15 sec.

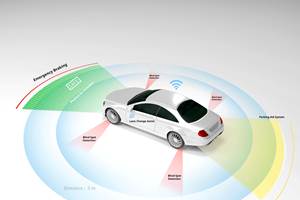

The two melt passages can be opened and closed by raising and lowering two so-called "bolts." When the bolt is up, that port is closed. When the bolt is down, resin can flow through that passage. During a die change, both bolts are down or open, so resin fills both ports. Once the passage to the new die is full of resin, the bolt for the previous production die is raised, blocking and sealing that passage and port. That die can then be changed for the next production job. Partially lowering the bolt into the feedblock preheats the melt passage to the new die before it goes into production. Each bolt contains a breaker plate and screen pack. If filtration isn't needed, the breaker plate can be removed.

Trendelkamp's quick die- and screen-change device opens and closes hydraulically. It comes in sizes for throughputs from 800 to 22,000 lb/hr and can be custom-built for any size, Trendelkamp says. A die-plate adaptor for each port allows a processor to use existing dies.

The technology is suitable for polyolefins, but probably not for PVC, according to the company.

Related Content

Non-Fluorosurfactant Peroxide Curable Fluoroelastomers

Solvay launches new high-performance Tecnoflon FKM without use of PFAs used as process aids.

Read MoreTracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.

Read More“Smart Nanocomposites” for Vehicle, Wearable Electronics and Buildings

OCSiAl’s graphene nanotubes combined with a TPU to fabricate nanocomposite sheets that can harvest electrical energy from sources of waste heat.

Read MorePrintable Thermoset Polyurethane

Chromatic 3D Materials launched ChromaMotive D65, designed for additive manufacturing.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More