Foaming Expands Possibilities for Wood-Fiber Composites

Over a dozen processors already foam wood-fiber composites and an equal number are experimenting with it. Foaming with wood cuts resin cost and weight in half and brings design advantages. But it also requires particular know-how in materials formulation and extrusion hardware.

Wood-filled plastic profiles are growing rapidly in non-structural wood-replacement applications like decking. But most processors of wood composites are now evaluating the newer alternative of foamed composites that are lighter and feel more like real wood. Foamed wood composites also accept screws and nails more like real wood than do their unfoamed counterparts. What's more, internal pressures created by foaming give better surface definition and sharper contours and corners than unfoamed profiles.

"Foam will be the next wave of wood replacement after decking," predicts Don Murray, industrial sales manager of American Wood Fibers, which sells wood flour and plastic masterbatches. "It's the next evolution."

"Foaming is a big cost saver," says David Swinscoe, plant manager at Iso-Teck in Pompano Beach, Fla. "It cuts your material costs in half." Reducing profile density by 20-25% saves roughly twice that much in material cost because the resin may be only 40-50% of the profile but is typically 80-90% of material cost.

Foamed composites also run at lower temperatures and faster line speeds than unfoamed ones, says Alan Franc, development manager at Clariant Additive Masterbatches. Clariant makes Hydrocerol endothermic foaming agents.

Virtually all builders of twin-screw extruders have run foamed wood-composite trials. "The whole industry is working on foam," says Al England, executive v.p. of Strandex Corp., which licenses wood-composite technology. "It will get us into other applications where composites can't go now." Floating docks could be one. The U.S. Navy funded a five-year, $10 million program at Washington State Univ. in Pullman, Wash., to develop foamed wood composites that could replace pressure-treated lumber. Dock repairs currently cost the Navy $250 million/yr.

Michael Reedy, president of Reedy International Corp., a supplier of chemical blowing agents, says he's working on around 75 new applications for foamed composites of a variety of natural fibers, including hardwood, softwood, rice hulls, kenaf, coconut husks, and cotton husks.

The earliest known foamed and wood-filled thermoplastics were based on polystyrene. Probably the first was an extruded pencil commercialized in the early 1970s by the Empire Co. in Shelbyville, Tenn., now part of Sanford Corp. It's foamed to nearly 50% density reduction and contains a high level of wood flour. Other early practitioners of foamed wood composites are Marley Mouldings in Marion, Va., which began foaming 3% wood-filled PS moldings in the mid 1980s, and Royal Wood in Phoenix, Ariz., which commercialized foamed, wood-filled ABS window blinds in 1995.

In the past three years, more foamed wood composites have begun to appear. They are based on ABS, ASA, SAN, PVC, and PP, and include monolayer, coextruded, and even tri-extruded profiles. Now foamed wood composites are popping up in bigger profiles with more complex shapes and material variations. Density reductions range from 5% to 50% and wood filler levels from 3% to 60%. Denser foam profiles can be joined like conventional wood and don't need end caps or edging to hide the open ends.

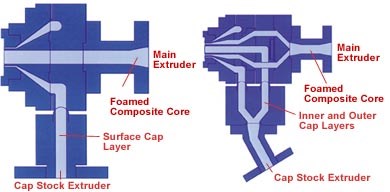

Most wood foam profiles are coextruded with unfoamed cap layers over foam cores. Cap layers may be a few mils thick to provide color, decoration, or uv stability. They can also be thick, highly wood-filled, and very dense for structural support.

More R&D is needed

Despite the flurry of commercial and development activity, the process of foaming composites is still a poorly understood black art. "There's some experience with styrenics and PVC, but there's not a lot with foaming polyolefin composites. It's still very early days," says William Crostic, commercial-development manager at BP Amoco Polymers. "Foaming wood composites is so new that you get a lot of opinions and not much experience."

Stabilizer and additive packages for foamed composites are largely undefined, particularly for resins like PVC and PP. "Wood is a complex chemistry. All wood has four components—cellulose, turpenes, oils, and lignins. Woods are all different, and some give off plasticizers," Reedy says. "Additives and stabilizers have to be tailored for each type of fiber and resin."

The many unknowns and technical challenges in foaming wood composites have caused some early pioneers to give up or scale back the level of foaming. Correct Building Products in Biddeford, Maine, commercialized a 60% wood-fiber PP board last year. The firm initially sought 30% weight reduction for the monolayer profile, but ended up with only 5% because it was too hard to maintain dimensional tolerances at the higher foaming levels.

Insufficient weight reduction and excessive voids killed a foaming effort by Countertops Inc. in Eau Claire, Wis. The firm uses a corotating twin-screw extruder to make 50% wood-filled solid HDPE deckboards called Ultradecking for a Midwestern building-supply chain.

A tricky mix

Foaming agents and stabilizers are two of many essential ingredients of the new wood replacements. Wood composites are typically foamed with 0.5-1.0% of an endothermic blowing agent, either liquid or powder. Since wood typically begins to decompose at 350-375 F, Reedy International developed a new stabilizer package that reportedly allows wood-filled PVC to withstand 392 F for 25 minutes without discoloration.

Composites with less wood fiber are generally easier to foam than more highly loaded ones, but wood-fiber type and size play a role. Longer fibers give the composite strength but also give the foaming gas a pathway to escape.

Foaming is easier with amorphous polymers like PVC and PS than with crystalline ones like PP or PE. Amorphous polymers generally have better melt strength, but crystalline resins have lower viscosities and accept higher filler levels. More viscous amorphous polymers make it harder to wet out wood flour and disperse it evenly, but they hold gas bubbles better.

Foaming in general reduces the stiffness and flexural strength of a profile. "A foamed profile typically will have a third to a half the flexural strength of the same or similar non-foamed material," says Chuck Cannon, director of business development at plastic lumber producer Mikron Industries in Kent, Wash. How great that penalty is depends on bubble size, filler level, filler particle size, and resin type. Foaming hurts the stiffness and flexural strength of polyolefins more than that of PVC. That's because vinyl is more compatible with wood fiber. Thus, polyolefins do not develop optimum strength even in solid form without coupling agents or compatibilizers.

Coextruding an unfoamed layer can restore the lost strength. Mikron's PP decking is coextruded with a highly wood-filled solid skin over a foamed composite core. The foamed core has a specific gravity of 0.3-0.5 g/cc. The outer shell has a specific gravity of just over 1.0 g/cc and makes up roughly 50% of the profile. It gives the profile sufficient strength to span up to 24 in., Cannon says.

Another way to add strength is to increase the ratio of polymer to wood flour, but that adds cost. A less expensive answer is to encapsulate wood fiber with wax or alloy it to the polymer with silane, maleic anhydryde, maleated PP or PE, or another coupling agent.

Coupling agents help solve another problem with foam. Gas bubbles and wood fibers open pathways for water to enter and mold to grow, says Scott Sackinger, manager of technology and quality at Louisiana-Pacific Corp. in Sherwood, Ore., which is developing foamed composites. "You have to be very careful not to have unwetted or un-encapsulated wood flour. Some products out there won't pass the stiffness and creep-recovery tests required by some building codes."

Amorphous styrenic resins like PS, ABS, ASA, or SAN yield stiffer foamed composites, but primarily because the wood content is lower.

Get the right hardware

Foamed composites need significantly different dies and extrusion equipment—especially more cooling. "Foaming brings a lot more complexity in terms of tooling and cooling," says Mikron's Cannon. "Your initial hope is that you can use existing tooling and cooling equipment, but it doesn't work out that way. You keep lengthening the cooling tanks, but eventually you simply run out of space." Mikron pioneered cryogenic cooling as one way to raise output of large foamed wood-composite profiles. The company built a whole new plant with eight extrusion lines to make its two- and three-layer foamed composites.

Dies are generally smaller for foamed than for unfoamed extrudates. A foamed composite has about a 2:1 expansion out of the die, whereas an unfoamed one has no die swell. At the Forest Product Laboratory's recent Woodfiber Composite Conference in Madison, Wis., Clariant presented data on a foamed composite profile that nearly doubles in size between the die and the calibrators. However, BP Amoco's Crostic says that allowing so much expansion hurts bubble development. "To get uniform cell size, you need to calibrate the profile when it is close to the size it has coming out of the die," he says.

Die shape is also different for foams. "The shape of the foamed profile out of the die doesn't look exactly like the final profile. It's distorted to fill the corners," says Thomas Hughes, v.p. at Extrutech International, which licenses foamed styrenic composite technology and supplies dies and turnkey systems.

Wood-fiber size affects ultimate properties. Davis-Standard Corp. says particle sizes of polymer and fibers should be similar—around -40 mesh. Others find that fiber-size distribution is what's important. Marley Mouldings specifies a particle-size distribution rather than a specific mesh size for its wood fillers. A combination of long and short fibers reportedly gives profiles extra strength.

A look at the action

Only around a dozen foamed wood-composite products are commercial so far—predominately lightweight PS profiles for window blinds and PVC or PP decking boards. Here's a look at the main players that have production experience foaming wood composites:

- Amesbury Group's Plastic Profiles Div. in Cannon Falls, Minn., is developing wood-filled foam profiles for window and door components. Amesbury aims to duplicate the density of pine, which requires foaming to about 20% weight reduction. Amesbury expects its product to be commercial before the end of the year.

- CertainTeed Corp. in Jackson, Mich., launched monolayer PVC foam decking containing 35-40% wood flour at the start of this year. CertainTeed achieves about 20% density reduction. CertainTeed also launched a monolayer railing system this year made of wood-filled PVC foamed to about 24% density reduction.

- Comfort-tex, headquartered in Albany, N.Y., bought Royal Wood's foamed composite window-blind technology and its plant in Phoenix. This Extrutech licensee uses ExtrusionTek Milacron conical twin-screw extruders. Comfort-tex belongs to Hunter Douglas, a maker of window blinds.

- Compos-A-Tron Inc. in Scarborough, Ont., a new Strandex licensee, plans to foam two-layer rails with a core of 55% wood-filled PVC and a solid PVC cap layer. It will use Strandex's PE and PVC formulations and Milacron conical twin-screws. Production is due to start in August.

- CPI Plastics Group (formerly Crila Plastics) in Mississauga, Ont., foams PS board products like decking, spa cladding, and moldings—all with 40-50% density reduction and a very little (<3%) wood filler for stiffening.

- Next month, Dry River Inc., a start-up company in Lowland, Tenn., will commercialize foamed decking made of PP and wood flour using technology licensed from Southern Composite Technologies in Newport News, Va.

- Iso-Teck has licensed Extrutech technology for the past three years to make foamed wood-filled window blinds. Iso-Teck also belongs to Hunter Douglas. It coextrudes 35 different decorative cap layers over the foam core. Iso-Teck is developing other foamed composite profiles.

- Jet Plastics in Los Angeles, also an Extrutech licensee, makes window blinds with a 10-20% wood-filled ASA foam core and a PVC cap layer. The foam core is reduced in density by 40-55% to 0.5-0.7 g/cc. Jet uses foaming agents from Accel Color and proprietary additives to dull the surface finish. It is developing foamed wood-composite siding.

- Marley Mouldings extrudes 3% wood-filled PS foam for moldings and wood-replacement trim. Its monolayer millwork profiles are milled or routered like conventional wood. Marley is developing profiles of 20% wood-filled PVC foam.

- Mikron foams a variety of wood-filled coex lumber replacements. It uses powdered PP from Solvay Polymers plus liquid and powdered foaming agents. Mikron's decking has an unfoamed outer layer of PP and 60% wood flour, while the foamed core is only 20% wood flour in a PP alloy foamed to 50% density reduction. Decking is produced on a Davis-Standard Woodtruder without predrying the flour. Mikron is the first to use cryogenic downstream cooling for foamed composites. Mikron also extrudes foam wood-composite window and door profiles with two and three layers, including a weatherable capstock. Mikron's plant has reached capacity and the firm is starting construction on a second plant.

- Plastic Extrusion Technologies Inc., a four-year-old custom extruder in Middlefield, Ohio, specializes in small wood-filled tubes and profiles. Some of them are foamed, like a 20% wood-filled PS tube with 40% density reduction.

- Polywood Products in Diamond Springs, Calif., makes a bendable product called Bender Board that replaces redwood and cedar boards used in landscaping and contoured concrete forms. Foaming makes profiles more flexible than the original wood product, which had to be presoaked before it would bend. Bender Boards have been commercial since 1999. They are made of 25% wood-filled PP impact copolymer that is foamed to 25-30% density reduction. In the near future, Polywood also plans to commercialize door frames, door stops, and other foamed composite millwork.

- Precision Composites, Phoenix, Ariz., bought the foam-composite board and millwork product line of Royal Wood Home Products. Precision uses conical twin-screws from Milacron to make boards from 3.5 to 11.25 in. wide.

- Profile Solutions, a custom profile extruder in Jacksboro, Tenn., has run successful trials of 10-20% wood filled PVC foamed to around 0.7 g/cc density (similar to wood).

- Tri-Ex Composites, an Extrutech licensee in Newnan, Ga., makes a three-layer foamed wood composite for hollow railings. It uses three conical twin-screw extruders and its own patent-pending technology. The white outer skin is uv-stabilized PVC. The foamed core is 10% wood-filled PVC. The inside layer of unfilled, solid PVC gives structural support.

- In January, Youngstown Plastics Tooling and Machinery, Youngstown, Ohio, started producing coextruded composite deck board with a foam core and solid skin. Youngstown uses single-screw extruders to run a PVC alloy filled with up to 50% wood flour and foamed to a specific gravity of 0.6 g/cc.

Related Content

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

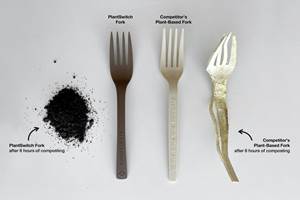

Read MoreAdvanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More

.png;maxWidth=300;quality=90)