How Efficient Is Your Mold Maintenance?

Mold performance and mold-maintenance efficiency are two very different but closely connected goals of today’s mold-repair shop.

Mold performance and mold-maintenance efficiency are two very different but closely connected goals of today’s mold-repair shop. Mold performance has been an issue ever since the first part hung up in a cavity. But maintenance efficiency—i.e., the approach used to repair molds—has taken a back seat to the overall task of producing plastic parts.

The idea of maintenance efficiency has always been more about making sure a mold is production-ready rather than how this is accomplished. If a mold-shop supervisor has more molds sitting red-tagged (needing work) than are getting pulled on a weekly basis, then is his shop efficient? Probably not. Will anybody notice? Probably not. So why is maintenance efficiency important if the molds are ready when needed?

Everything in plastics manufacturing gets scrutinized for cost-effectiveness nowadays. Every step—from the inception of the part design to the mold design, the mold build, and finally production—has to pass muster. But maintenance is normally ignored and left to the devices of craftsmen behind the bench.

The rule has simply been to do whatever it takes to get a mold back in the press and keep it running. Do that, and all else is forgiven. But in today’s highly competitive market, companies are beginning to look closely at the strategy employed to meet mold-performance or production goals. Budget factors such as excess tooling usage, unscheduled mold stops due to maintenance-related issues, and excessive toolroom labor hours because of flashed manifolds, damaged tooling, water leaks, and non-conforming product are no longer considered just “costs of doing business.”

Mold owners and company bean-counters are now giving closer scrutiny to mold maintenance. Common shop issues that we deal with every day are having costs associated with them so that they can be measured by the people footing the mold repair bills. So be prepared. Henceforth, we must concern ourselves with how we maintain molds.

| TABLE 1—SHOP GOALS | |

Mold Performance | Maintenance Efficiency |

| • Improve production reliability | • Optimize mold-repair hours |

| • Increase cavity efficiency | • Reduce tooling usage |

| • Maximize mold and tooling life | • Reduce maintenance mistakes |

| • Decrease cycle time | • Train new employees faster |

| • Improved part quality | • Improve shift-to-shift communication |

| • Reduce scrap rates | • Improve mold knowledge and defect awareness for better troubleshooting |

• Standardize repair methods and procedures for consistency | |

Three typical diseases

To get a better understanding of how mold performance and maintenance efficiency are connected to profitability, let’s examine the basic goals of each (see Table 1 above). As with every goal to improve a process, there are usually challenges or barriers that stand in our way. When you put an unhealthy maintenance shop under the microscope, it usually turns out to be harboring one of three common viruses.

- Time limitations: An excessive MPP or Mold Pull Pace—pulling molds faster than you can get them production-ready (green-tagged)—can be the result of shop downsizing or “no hire” practices. In addition, the toolroom supervisor may be tasked with other responsibilities besides mold management—such as building new molds or maintaining plant equipment. Likewise, repair technicians may be tasked with other responsibilities such as ancillary and plant equipment maintenance.

- Corner-office culture: It’s typically not maintenance oriented, and/or has no clear reporting structure for mold repairs.

- Employee resistance: Toolroom and production workers, both salaried and hourly, often do not want to give up the freedom and monetary benefits that come with freelancing or outsourcing repairs, with its accompanying lack of accountability. Other hard-to-kick habits are the prestige of being “the shop king” who knows the most about all the molds or the “hero firefighter” of the day.

How do you begin?

Regardless of the above barriers, we must begin to strategize for improvement. Remember that you are dealing with seasoned, skilled tradesmen who don’t favor being “jerked around” on the assumption of overnight success. Many maintenance-efficiency programs have been tried and failed because the repair techs knew that all they had to do is “weather it out” and things would soon return to normal…meaning zero expectations and zero accountability.

First, you must choose the parameters that you want to improve, then establish a baseline of measurable data to use as a barometer. For this article we will discuss the first three steps of a six-step process:

- Clean up and organize your shop: It is hard for anyone to believe that anything will be improved in a repair shop that looks like a pigpen. Clean up shelves, benches, floors, and empty chip trays and put tools away. Tag and organize tooling that has been removed from molds. Once the shop is cleaned, take an hour every Monday morning to keep it that way.

- Stop the bleeding: Let everyone know (through meetings, bulletin-board posts, e-mail, and word of mouth) that mold-stop reasons are now being monitored and will be measured on a monthly basis. Just publicizing this fact will immediately help reduce the occurrence of mold stoppages due to inattention or carelessness. The message should be that accountability begins now.

- Assess the damage: Keep it simple. Utilize the reports from a CMMS (computerized maintenance-management system) or count mold-stop occurrences manually to find out where you are. If you have a CMMS, see the Unscheduled Stop Report. Use it to categorize your unscheduled mold-stop events by reason, frequency, and corrective-action costs (labor, tooling, and total).

Let production know you are monitoring their issues also, and ask them to please let the toolroom know if there is anything it can do to help correct a recurring issues such as sticking parts or runners, gas burns, non-fills/short shots, poor part appearance, or problems that require extreme process tweaking.

As you target the most frequent problems, you will begin to see a decline in unscheduled downtime. That accomplishes several things quickly:

- It will allow more time for you to concentrate on proactive maintenance.

- It provides measurable data with which to demonstrate improvement to the unbelievers.

- It reduces operating costs (labor and press downtime).

- It improves ability to meet production schedules.

- It improves relations between tooling and processing departments (this alone is worth the exercise).

Drilling down

After compiling the list of unscheduled mold-stop reasons over one to six months (depending on your MPP), post the list in the toolroom and send an e-mail to processing and other team members about your planned targets. Many problems will be corrected easily, just by focusing on them. The challenge is to agree upon an action plan and assign responsibility for specific tasks to reduce the frequency of targeted mold stoppages.

| TABLE 2—UNSCHEDULED MOLD-STOP ANALYSIS | |||||

| Mold Stop Reason | Stop Count | Labor Hours | Labor Cost | Tooling Cost | Total Cost |

| Mold Damage | 17 | 271.75 | $13,587.50 | $27,968.26 | $41,555.76 |

| Low Mold Cavitation | 9 | 196.50 | $9,825.00 | $13,553.00 | $23,378.00 |

| Part Flashing | 14 | 130.50 | $6,475.00 | $6,496.25 | $12,971.25 |

| Electrical Issues | 5 | 45.50 | $2,275.00 | $9,765.00 | $12,040.00 |

| Heater Issues | 4 | 74.50 | $3,725.00 | $1,010.00 | $4,735.00 |

| Incorrect Mold Assembly | 3 | 6.50 | $325.00 | $3,750.00 | $4,075.00 |

| Parts Sticking | 7 | 54.80 | $2,740.00 | $900.00 | $3,640.00 |

| Internal Water Leak | 6 | 57.25 | $2,862.50 | $0.00 | $2,862.50 |

| Ejector Plate Won’t Function | 4 | 45.00 | $2,250.00 | $496.00 | $2,746.00 |

| Flashed Manifold | 4 | 53.75 | $2,687.50 | $0.00 | $2,687.50 |

| Part Functional Issues | 3 | 45.50 | $2,275.00 | $0.00 | $2,275.00 |

| External Oil Leak | 4 | 37.00 | $1,850.00 | $0.00 | $1,850.00 |

| Broken Gate | 3 | 36.50 | $1,825.00 | $0.00 | $1,825.00 |

| Metal in Gate | 4 | 20.00 | $1,000.00 | $0.00 | $1,000.00 |

| Scuffed Tooling | 1 | 14.00 | $700.00 | $0.00 | $700.00 |

| Nonfills | 2 | 12.50 | $625.00 | $0.00 | $625.00 |

| Part Dimensional Issues | 3 | 11.00 | $550.00 | $0.00 | $550.00 |

| Galled Tooling | 1 | 10.50 | $525.00 | $0.00 | $525.00 |

| Residue Leaching Out | 1 | 5.50 | $275.00 | $0.00 | $275.00 |

| Warped Parts | 1 | 5.00 | $250.00 | $0.00 | $250.00 |

| Flashed Mold | 1 | 5.00 | $250.00 | $0.00 | $250.00 |

| 97 | 1138.55 | $56,877.50 | $63,938.51 | $120,816.01 | |

Table 2 shows an example of what you can learn from charting unscheduled mold-stop reasons. In this case, production stopped for 21 different reasons. At the top of the list is mold damage, the #1 issue based on total money spent on corrective actions. This should be the first-priority target for the efficiency team’s action plan. It requires a full investigation of the 17 occurrences, broken down by mold number, tool configuration, tooling components damaged, press number, shift, personnel involved, etc.

It's also important to target (and publicize) the mold-shop issues (marked in blue) that are due to simple carelessness or ignorance.

The next article will discuss the final three steps of the optimization program.

Steven Johnson worked as a toolmaker for 26 years, rebuilding and repairing multicavity molds for Calmar Inc. and then as mold-maintenance engineer for Hospira Inc., a medical device manufacturer. Today, he is the maintenance systems manager for Progressive Components and has his own business, MoldTrax in Ashland, Ohio, which designs and sells software for managing mold maintenance (www.moldtrax.com). He can be reached at steve@moldtrax.com or (419) 289-0281.

Related Content

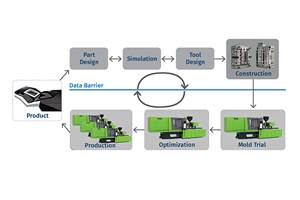

Injection Molding Simulation Meets the Real World

Direct data interface between molding simulation and the injection machine links the computer model to the real-world process. This can improve results from product and mold design through ongoing production. A case study demonstrates these benefits for automotive components in a family mold.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

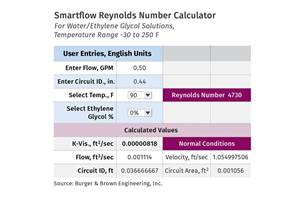

Read MoreCooling Geometry and the Reynolds Calculation

The original Turbulent Flow Rate Calculator worked well with a round circuit diameter, such as a drilled passage, but not as well using hydraulic diameters. Here’s how the problem was fixed.

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

.png;maxWidth=300;quality=90)