How to Clean a Flashed Hot Manifold-Part Three

We left off last month with all 16 nozzles removed from the manifold (with the tips protected by tape) and still wired to the electric box.

We left off last month with all 16 nozzles removed from the manifold (with the tips protected by tape) and still wired to the electric box. This arrangement allows the nozzles to be cleaned yet still connected, which cuts out about three hours of rewiring time. It also means that you must move the nozzles and electric box around as a group, taking care not to damage the housings, heaters, or wire connections. Use a plywood board or tray large enough to carry the nozzles and electric box when moving them to another area of the bench.

While we clean the nozzles, the ultrasonic tank is busy cleaning the retainer plate, which should not take more than an hour or two to remove all traces of degraded plastic, eliminating this worry during assembly.

Cleaning nozzles

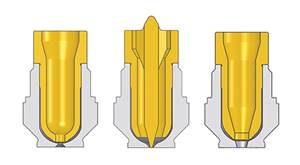

The degree of cleaning a nozzle needs depends upon the clearance around the nozzle body and the cavity insert as well as the sealing/stacking surfaces of the components. The entire nozzle does not need to be spotless, with all traces of plastic removed, to be reinstalled and seated properly. This can be accomplished a number of ways, depending upon the type of nozzle and how it is heated.

Clean the nozzle housing front and back to remove enough plastic around the nozzle body so it can easily enter the back of the cavity without interference. Plastic around the front tip must obviously be removed if it stacks and seals against the back of the cavity gate insert.

Then clean the back of the nozzle seats and run them over a medium Norton stone to make sure they are flat and smooth. If a depression is noted, it must be measured to ensure that the depth of the depression is no greater than 0.001 in., or a slow leak could occur here.

Cartridge-heated nozzles

If the nozzle has an internal cartridge heater that isn’t stuck, simply pull it out (make sure it is numbered) and use a soft wire wheel to clean plastic off the body, taking care not to damage or reconfigure the tip.

Some technicians like to burn plastic off nozzle bodies with a torch before disassembly and while the manifold plate is standing up on the bench. If this is your preference I would advise using a temperature controller instead of a torch to heat up the nozzles just enough (usually around 250 to 300 F) to remove the plastic easily, which makes this operation safer and won’t stink up the shop.

If the heater cartridge is stuck, then you can either drill it out (destroying the heater) or leave it alone and clean off the nozzle body with a brass pick or scraper. You can also clamp it in a vise with soft jaws and use a wire wheel in an air drill. Standard cartridge heaters are typically 0.005 in. smaller than the nozzle bore, but if not cleaned periodically they will stick hard. If you have to drill out a heater, use the next size smaller bit, taking care not to scar the bore walls. Resist the temptation to perform this operation by eye at the bench with a hand drill–use a lathe to do it right.

You want to drill out all but the outer skin of the heater, allowing you to slip a prick punch behind the skin, bend it in far enough to grasp it with needle-nose pliers, hose it down with WD-40, and work it out. It’s a time-consuming task that is best prevented through regular cleanings and application of an anti-seize product like Watlow Release and Heat-Transfer Fluid (from Watlow Electric Mfg. Co., St. Louis) before installing the heaters.

Cast-in heated nozzles

These are more troublesome to clean because of the attached heater and thermocouple wires, which should not be removed for normal maintenance. These nozzles also require great care not to poke holes in the embedded heaters or damage the leads and ceramic connectors. Never use a torch on these nozzles, and clean only what is necessary to reinstall the nozzles.

Band-heated nozzles

These are my favorite simply because the heaters and thermocouple wires are usually removed easily, making cleaning the body much easier via ultrasonic tank. Any time a component can be cleaned in an ultrasonic tank, the process will be speeded up. The only problem usually stems from removing the thermocouple. Some brands require you to straighten out the tip before you can slip it through the nozzle, which can stress-crack and ruin the thermocouple. If this is the case, and the manifold is extremely time-consuming to work on, then spend the money and replace all the thermocouples instead of risking creating an opportunity for them to fail, which would negate all your previous labor hours.

Cleaning manifolds

Once the nozzles and manifold are cleaned, run a medium Norton stone over the manifold while looking for burs and hobbed areas around the seal points. If you have a “rock” (granite surface plate) handy, you could give the manifold and bridges or crossovers a quick check for flatness. (Whether or not you will take this opportunity will probably depend upon the number of white shirts breathing down your neck to get the mold back into production.)

Judging manifold flatness and seal-area hobbing or pitting is usually influenced by how the nozzles seal against the manifold. Nozzles that are independently bolted to or screwed into the manifold are more forgiving of slight imperfections than those counting on only an expansion fit between plates and spacers. As rule, if you can rock any of the components on a surface plate more than 0.005 in., then it is time for a “dusting”–i.e., grinding the surface just enough to flatten it, removing high spots or hobbed/pitted areas.

Dirty electrical boxes

Most hot-runner electrical boxes sit on top of the mold directly over the manifold and are usually bolted directly to the top of the plates with a pocket cut out to route the wires to the box connectors. The problem with this set-up is the continually abused electrical box also acts as a chimney for the vent gases and residues. Even though the box access panels are normally sealed, the gases seem to find their way inside the boxes, coating everything in sight. I have been told by some electricians this gummy mess can cause the connections to short out on occasion. I’ve been told by others that only certain residues will support an electric current, but no one seems to agree on exactly which ones. If a chemist is reading this, please send me an e-mail and share your knowledge.

In the meantime, set your electrical boxes on a 1-in. spacer that has been slotted all the way through so that the gases can escape, and install a rubber gasket in the bottom of the box to feed the wires through, thus keeping the inside of the box and connectors cleaner.

Now for reassembly

Once the plate counter-bores, nozzles, and manifold are clean, stoned, and wiped down, it is time to reorganize things and get ready for the assembly stage. Wipe off the bench top, sweep the resin off the floor, and put away your cleaning tools.

Lay the manifold retainer plate face down on some rails (“parallels”) to keep the nozzle tips from contacting the bench top as they are placed in the pockets. Bring the nozzles (still connected to the electrical box) over to the plate and lay them out in a pattern resembling how they will go in. As you install the nozzles, make sure they bottom out in the pocket. Once all nozzles are in position, refasten the electrical box.

Using depth micrometers, verify that all nozzles are the same height (usually within 0.002 in.). As a reference, I like to use an old support post ground to the same height the nozzles should be when installed. When you are satisfied, set the manifold back onto the nozzles. You could check the manifold height at this stage for flatness, but I think it’s more accurate to bolt it down to the proper torque value first, and then measure it for flatness. I like to tighten manifold bolts starting from the inside, working to the outside in a crossover pattern. Apply a good anti-seize compound to all bolts on the threads and under the bolt heads. Flatness variation should be no greater than 0.003 in. across the manifold.

After this final step, hook up the controller and check for any dead shorts, then heat up to about 200 to 300 F to make sure everything works properly before bolting on the retainer plate and reassembling the “A” side. Before you install the A-side cavity plate, make sure the manifold and nozzles have cooled down to match the temperature of the “cold” (room-temperature) cavity plate.

If all is well, install the retainer plate and remaining components using anti-seize compound on everything in sight.

Final check

A typical procedure includes first running water through the manifold plates to keep things from overheating. Then turn on the controller and ramp up the heaters to processing temperature. Next, verify that all heaters and thermocouples are working properly. Let the system sit for 15 min and then shut off the controller. Let water continue to flow and cool off the plates. When manifold A-side plates are cooled to same temperature as the “B” half, assemble the mold.

After the final check is completed, fill out any required documentation, change the mold status, and relax a bit . . . for the next encapsulation is right around the corner.

Steven Johnson worked as a toolmaker for 26 years, rebuilding and repairing multicavity molds for Calmar Inc. and then as mold-maintenance engineer for Hospira Inc., a medical device manufacturer. Today, he is the maintenance systems manager for Progressive Components and has his own business, MoldTrax in Ashland, Ohio, which designs and sells software for managing mold maintenance (www.moldtrax.com). He can be reached at steve@moldtrax.com or (419) 289-0281.

Related Content

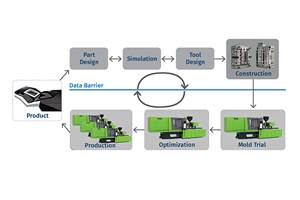

Injection Molding Simulation Meets the Real World

Direct data interface between molding simulation and the injection machine links the computer model to the real-world process. This can improve results from product and mold design through ongoing production. A case study demonstrates these benefits for automotive components in a family mold.

Read MoreHot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

How to Clean a Flashed Hot Manifold-Part Two

Already a familiar sight on European store shelves, the eye-catching appeal of "IML" is gaining traction among North American injection molders. The latest tooling and automation designs can handle the higher volumes needed here.

Read MoreHow to Clean a Flashed Hot Manifold-Part One

As I rounded the corner of our shop, I was confronted by a large flock of white shirts gathered around a mold on my bench.

Read More

.png;maxWidth=300;quality=90)