Industry Expands Again

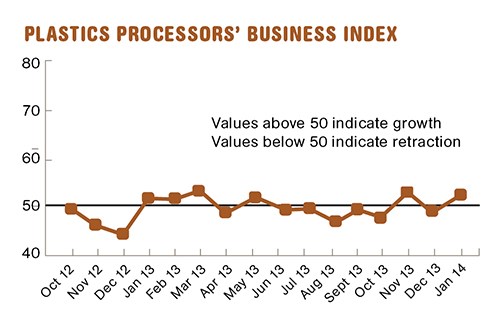

January was the third month in a row and the fifth time in six months that index was higher than it was one year ago.

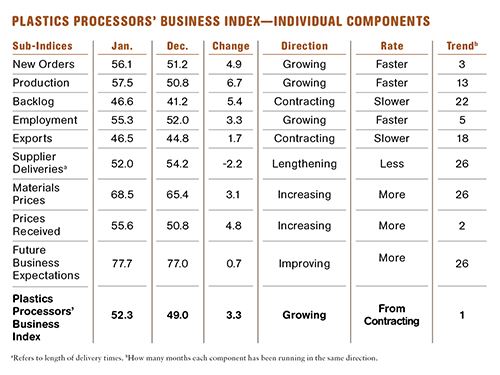

With a reading of 52.3, Gardner’s Plastics Processors’ Business Index showed that the market grew for the second time in three months. The level of business activity has been picking up since last August. The rate of growth in January was the third fastest since May 2012. Compared with one year ago, the index was up 1.4%. January was the third month in a row and the fifth time in six months that index was higher than it was one year ago.

New orders increased for the third straight month. The rate of growth in new orders was the fastest since March 2013. The rate of growth in production jumped significantly in January after slowing noticeably in December. Production is expanding at the second fastest rate since May 2012.

Backlogs continue to contract, though. Since December 2012 the rate of contraction in backlogs has slowed. This suggests that there could be some modest improvement in capacity utilization in 2014. Exports contracted at roughly the same rate they have since the summer of 2012. Supplier deliveries are still lengthening, but doing so at one of the slowest rates in the survey’s history.

Material prices had been increasing at a slower rate throughout most of 2013. But over the last two months, they have increased at a significantly faster clip. Prices received are increasing at a faster rate as well, though far below that of material prices. Future business expectations are noticeably higher than they were throughout 2013. In fact, future business expectations are their second highest level since the index began in December 2011.

Larger processors are still performing better than smaller ones. Facilities with more than 50 employees generally saw better business conditions in January. These plants have grown in three of the last four months. Smaller processors are doing better than they did in most of 2013, but are still lagging the larger processors. Facilities with 20-49 employees have grown two of the last three months, but the rate of growth has been barely positive. Facilities with fewer than 20 employees continue to contract, but their index is at the second highest level since July 2012.

After two months of contraction, the New England region expanded at the fastest rate in January. Its rate of growth in January was the fastest of any region in any month in the history of this index. The West North Central region had the second fastest rate of growth and grew for the second time in three months.

Future capital spending plans increased 4.8% compared with last year. This was after the one-month rate of change contracted in December for the first time in survey’s history. It appears that future capital spending plans are slowing down slightly. But, if the overall trend in the industry continues to be up, then future spending plans should turn back around soon.

ABOUT THE AUTHOR

Steven Kline Jr. is part of the fourth-generation ownership team of Cincinnati-based Gardner Business Media, which is the publisher of Plastics Technology. He is currently the company’s director of market intelligence. Contact: (513) 527-8800; email: skline2@gardnerweb.com; blog: gardnerweb.com/economics/blog.

Related Content

What to Do About Weak Weld Lines

Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.JPG;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)