Industry & Technology News - December 2010

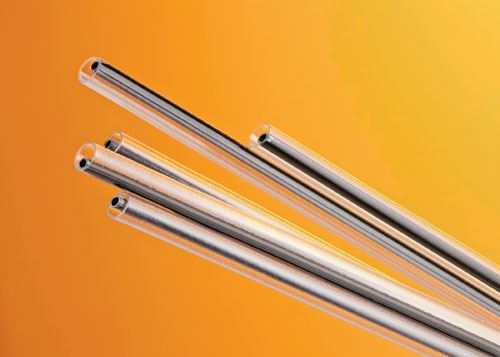

Novel TPE/Polyimide Medical Tubing Through a special manufacturing process, TPE tubing with one or more lumens is being extruded inside thermoset polyimide medical tubing.

Novel TPE/Polyimide Medical Tubing

Through a special manufacturing process, TPE tubing with one or more lumens is being extruded inside thermoset polyimide medical tubing. PolyMedex Discovery Group, Putnam, Conn., developed this approach. Thermoset polyimide (PI) has a tensile strength of at least 20,000 psi (139 MPa), which is 30% higher than high-performance thermoplastics such as PEEK. Due to its hard, glossy surface, PI is also good for device working channels, improving passability of metal devices such as implants. Further, it resists the harshest chemicals and can hold ID tolerances of ±0.0002 to 0.0005 in. (0.0051 to 0.013 mm), suiting it to small-diameter vascular device assemblies. The greatest limitation of thermoset PI is that it is available only with a round single lumen and is difficult to bond, color, or heat-form. In contrast, TPEs can be extruded in unlimited configurations and are heat-formable to create catheter components like tips and flares for connector fittings. PolyMedex fabricates and cures the PI tubing first and then extrudes the TPE.

(860) 928-4102 • polymedexgroup.com

selective-grinding and dry-sortation process

At K 2010: Squeeze Tubes Made In One Step by Bi-Injection, IML

Last month’s K 2010 show in Germany saw a new achievement for multi-injection molding and in-mold labeling (IML). A process developed by Dutch packaging firm Plasticum Group BV molds squeeze tubes in one step, without the usual separate steps for extruding the flexible body and molding and assembling the shoulder, neck, and cap. As demonstrated on an Engel e-motion T 280-ton all-electric tiebar press with a rotating “cube” mold from Otto Hofstetter AG, the process starts with rolling PP in-mold labels outside the press and inserting them into four annular cavities (using Beck Automation robotics). Then soft PP copolymer is molded inside the labels. The mold opens, rotates 180°, and PP homopolymer is injected by a second barrel mounted on the moving platen to form the integral flip-top closure. The robot flexes the living hinge to close the caps before the finished tubes are ejected. Cycle time was 12.5 sec. Plasticum says that eliminating the conventional tube shoulder cuts weight by up to 40%.

+31 13 465 7465 • plasticumgroup.com

(717) 764-6818 • engelglobal.com/na

Three Big Materials Acquisitions

DAK Americas LLC, Charlotte, N.C., agreed to acquire the PET business of Eastman Chemical Co., Kingsport, Tenn. The sale includes 1.35 billion lb of capacity at Columbia, S.C., and IntegRex PET polymerization technology. DAK, a unit of Alfa of Mexico, is already the second largest PET producer in the Americas. Eastman retains its copolyesters and Tenite cellulosic businesses.

Meanwhile, Teknor Apex Co., Pawtucket, R.I., has acquired the Sarlink TPV business of DSM Thermoplastic Elastomers, Leominster, Mass. The sale includes employees, technologies, compounding capabilities, and Sarlink sales operations on three continents.

In addition, Ashland Inc., Covington, Ky., has agreed to sell its global distribution business to TPG Capital, a private investment firm based in San Francisco. Ashland Distribution supplies thermoplastics, composite resins and reinforcements, and chemicals. Its thermoplastic distribution business is based in Columbus, Ohio.

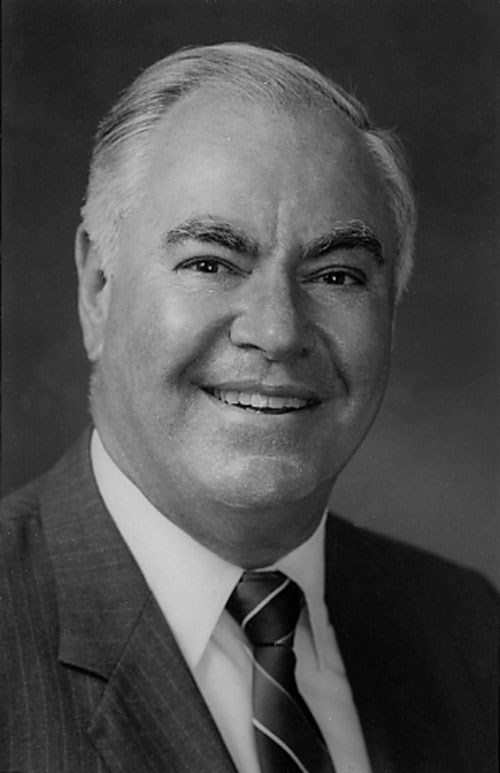

Sheet Legend Frank Nissel Retires from Welex

Frank Nissel, who for the last 44 years has pioneered in sheet extrusion, retired last month from Welex Inc., Blue Bell, Pa., where he spent most of that time as president of the company. Nissel’s career in plastics spanned 63 years. Before joining upstart Welex in 1967, he worked for Union Carbide and in 1956 co-founded machine builder Prodex (later part of HPM). Under his direction, Welex became a global powerhouse in sheet extrusion. He built the first commercial coextrusion line, developed vented extrusion, and invented the Autoflex adjustable die for sheet and cast film. Nissel was inducted into the Plastics Hall of Fame in 2000. Nissel, 84, will continue to serve on Welex’s board of directors as chairman emeritus.

Read Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)