Industry & Technology News: February 2010

First Large Automotive MIDs with LDSThe German “MID Industry Award” for 2009 was given to the PBT steering switch for the new BMW Z4 Roadster.

First Large Automotive MIDs with LDS

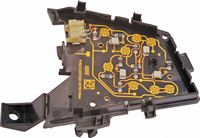

The German “MID Industry Award” for 2009 was given to the PBT steering switch for the new BMW Z4 Roadster. The switch is said to be the first large commercial molded interconnect device (MID) for automotive made with the laser direct structuring (LDS) technique. It measures 70 x 67 mm x 40 mm high and weighs about 20 g. Previous LDS/MID automotive parts have been tiny sensors weighing just a few grams.

The part was injection molded by TRW Automotive Systems GmbH in Germany using Pocan DP T 7140 LDS compound from Lanxess AG (U.S. office in Pittsburgh). This material’s high heat resistance (HDT of 250 C/482 F) allows for lead-free, vapor-phase soldering at 235 C. The LDS technique, developed by LPKF Laser & Electronics AG (U.S. office in Tualatin, Ore.), allows circuitry to be “drawn” on a part with a laser beam, which activates a special additive that allows for selective plating of metal onto the lines of circuitry.

(800) 526-9377 • us.lanxess.com; (800) 345-5753 • lpkfusa.com

K-Tron Is Sold

Hillenbrand, Inc., Batesville, Ind., the holding company for Batesville Casket Co., a leader in funeral services products, has signed a definitive agreement to acquire K-Tron International, Pitman, N.J. A well-known maker of materials-handling equipment, K-Tron will operate as a wholly owned subsidiary of Hillenbrand.

PolyOne Acquires New England Urethane

PolyOne Corp., Cleveland, has acquired New England Urethane, Inc., North Haven, Conn., a TPU compounder specializing in the healthcare market.

(866) 765-9663 • polyone.com; (800) 760-0638 • neuinc.com

Cordless Phone from Biopolymer

Telecom Italia’s new Eco. Cordless phone has a shell injection molded from Ingeo polylactic acid (PLA) biopolymer, made by NatureWorks LLC, Minnetonka, Minn. Molded by Femto Engineering S.r.l. in Italy, the phone gains the necessary toughness from an impact modifier masterbatch made by Sukano Products Ltd. of Switzerland (U.S. office in Duncan, S.C.).

Other recent Ingeo PLA applications include snack packaging film for Frito-Lay SunChips, coated hot cups on KLM flights, and car mats for the Toyota Prius.

(952) 742-0400 • natureworksllc.com; (888) 278-5266 • sukano.com

Suppliers to Phase Out Decabrom

The U.S. Environmental Protection Agency announced in December that it had negotiated agreements with several companies to phase out over the next three years a popular plastics flame retardant, decabromodiphenyl ether (decaBDE), also known as decabromodiphenyl oxide (DBDPO) or “decabrom.” This product has been used for close to 40 years and has been studied extensively. EPA is not banning decaBDE but is encouraging its discontinued sales and use. EPA statements call it a “persistent and toxic chemical” that “potentially causes cancer and may impact brain function” and also “can degrade to more toxic chemicals that … are hazardous to wildlife.” Companies announcing that they will phase out decaBDE include Albemarle Corp., Baton Rouge, La.; Chemtura Corp., Middlebury, Conn.; and Israel’s ICL Industrial Products, said to be the largest importer of the material to the U.S. (ICL-IP America is in St. Louis.) Statements from these companies call decaBDE “one of the world’s most effective and widely used flame retardants” and note that hundreds of scientific studies show that “DecaBDE does not pose any significant risk to the environment or human health.” In fact, a European Union risk assessment in May 2008 found no need for restricting decaBDE, and the Swedish Chemicals Inspectorate decided last March not to pursue any national restrictions.

As we reported last month, Albemarle recently announced an alternative FR product, called GreenArmor. Chemtura and ICL both say they are developing alternatives also, some of which Chemtura plans to introduce this year.

(800) 535-3030 • albemarle.com; (800) 243-2650 • chemtura.com; (877) 661-4272 • iclfr.com

Read Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=970;quality=90)