Ingeo Biopolymer Tops 'Smallest Carbon Footprint' List

NatureWorks' online calculator offers brand owners and researchers a tool for comparing GHG emissions and the non-renewable energy use of products made from different plastics.

With many consumer product brands increasingly looking to reduce their carbon footprint, several different types of plastics recently have had reassessments of their eco-profile—energy usage and greenhouse gas emissions (GHGs). In step with this market trend, there has been an update to the profile of Ingeo biopolymer from NatureWorks, Minnetonka, Minn. Called “Life Cycle Inventory and Impact Assessment Data for 2014 Ingeo Polylactide Production”, the article was also just recently peer reviewed and approved for publication in the June 2015 issue of Industrial Biotechnology by an independent panel of experts.

The eco-profile of a polymer gives information such as the total energy and raw materials consumed, and the total emissions to air, water, and soil from the cradle to the finished polymer pellet. A life cycle inventory (LCI) is an essential input to any full LCA conducted on consumer products made from that polymer.

“Our most recent eco-profile in 2010 was calculated using the methodology, the modeling software, and core database in place at the time. The same approach was used by such industry organizations as Plastic Europe since the beginning of the 1990s to calculate the eco-profiles for the fossil-based polymers. However, LCA tools and databases have progressed in the past four years, and we decided it was time to recalculate the eco-profile based on those advancements,” says NatureWorks environmental affairs manager Erwin Vink.

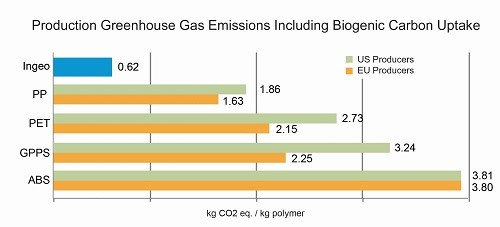

Overall, the publication of the new Ingeo life-cycle assessment (LCA) shows that GHGs and energy usage during its manufacture is lower than all commonly used plastics, including PP, PET, GPPS and ABS. The article documents the energy and GHG inputs and outputs of the Ingeo production systems, the revised 2014 Ingeo eco-profile, and the calculation and evaluation of a comprehensive set of environmental indicators. It also addresses topics such as land use, land-use change, and water use.

To help brand owners and researchers in the direct use of this life-cycle assessment data, NatureWorks now has available an online calculator--Environmental Benefits Calculator--providing them with a tool for comparing the net GHG emissions and the nonrenewable energy use of products made with different plastics. The calculator provides an intuitive interface from which manufacturers and brands can input data details and receive instantaneous feedback on the environmental impact of the materials they are using.

This revised eco-profile (the cradle-to-polymer life cycle inventory data), which is based on the latest version of Thinkstep’s GaBi LCA software and database, follows the ISO 14040 and 14044 standards and reinforces the fact that the production of Ingeo polymer emits fewer GHGs and consumes less non-renewable energy compared to other commonly used plastics.

Want to find or compare materials data for different resins, grades, or suppliers? Check out Plastics Technology’s Plaspec Global materials database.

Related Content

-

Cling Wrap Made from Potato Waste

Australia’s Great Wrap to expand into U.S. with home compostable cling wrap and its refillable dispenser made from recycled PET bottles.

-

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

-

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.