K 2004 Wrap-Up on Recycling & Scrap Reclaim: Turn Trash to Cash with New Compactors, Shredders and Grinders

Topping recycling news at the latest giant K Show in Dusseldorf, Germany, were new compactor technologies for films and foams that can densify plastic waste for recycling and even mold finished parts—not just save space in a landfill.

Topping recycling news at the latest giant K Show in Dusseldorf, Germany, were new compactor technologies for films and foams that can densify plastic waste for recycling and even mold finished parts—not just save space in a landfill. Other recycling developments include a small in-line solid-stater for PET and a new disc compactor for EPS.

News at the show in shredders and grinders includes the first shredder with a permanent-magnet, synchronous torque motor and several huge new grinders targeting high throughputs of tough stuff like PP raffia fiber.

Compacting EPS

Maskinfabrikken RUNI ApS in Denmark showed an un usual ma chine and service for users of EPS boxes like fish pack ers and canneries to help them compact their foam waste for recycling or disposal. RUNI's compactor makes 16 x 16 in. blocks of solid PS, reducing the EPS bulk by 50:1. Compacted blocks are only slightly fishy smelling.

RUNI buys the compacted EPS blocks from fish packers and resells the material to Chinese molders. Over the past four years, RUNI says it has sold over 100 shipping containers of compacted EPS.

RUNI's screw compactor starts with a precrusher that breaks up big hollow parts before feeding the material into the hopper. Model SK240H uses a 7.5-hp main drive to compress the EPS, while a 0.75-hp hydraulic pump powers electronically controlled jaws that keep constant pressure on the material in the screw, resulting in consistent output density. It processes 165 lb/hr of EPS or roughly 110 fish boxes and lids. A larger model SK370H handles 440 lb/hr or about 300 fish boxes.

Compressed EPS blocks can be sawed, cut with a knife or broken by hand, typically into about 40-in. sections weighing 20 to 25 pcf. There are three RUNI units in the U.S., including one at Tampa Bay Fisheries in Tampa, Fla., which reports substantial savings in waste disposal.

RUNI's model SK240H can use a larger motor (10 hp) to compact 4400 lb/hr of textile fiber from old tires. Tire fiber is compacted into a continuous mat and stuffed into an endless tube of PS film for disposal. (The film tube controls dust.)

Another recent RUNI compacting application, developed for a Norwegian film recycler, dewaters washed agricultural film. Water content is reduced from 40% down to 8% without heat, just by squeezing.

Beyond briquettes

Promeco Srl in Como, Italy, a builder of short, counter-rotating twin-screw briquetters, designed a version to make profiles out of mixed plastic waste for fence rails, pallet spacers, agricultural poles, bricks, and car stops. It uses the same extruder as the briquetter but different dies. Output is also reduced about 25% to get a better surface.

The machine uses the frictional heat of extrusion plus electric heater bands to melt the plastic and bind 15% to 20% non-plastic ingredients like shredded paper, sawdust, or wood chips. The machine comes in two sizes: Type 300 has 2:1 L/D (600 mm long, 300 mm diam.) and output of 1750 lb/hr of profile or 2600 lb/hr of briquettes. Type 600 has 1:1 L/D (600 mm long and wide) and puts out 6600 lb/hr of profile or 8800 lb/hr of briquettes. Since the extruders are so short, moisture is removed via the infeed opening rather than vents.

Strautmann Umwelttechnik GmbH in Melle, Germany, another builder of briquetting machines, exhibited its low-heat briquetting process for PET bottles, foamed PS, and PE film. Material is sucked into a compression tunnel at a rate of 4.5 to 6.5 lb/min. Rigid materials are forced into the compression channel with a pressure blade inside the hopper. A heated tunnel surface melts only the outer 1 mm of the briquette to impart a smooth finish and help hold it together. Fumes from melting the surface are passed through an air filter.

Strautmann's Brikettierpresse comes in three sizes. The smallest is BP100, which processes about 330 lb/hr of film scrap into briquettes measuring 110 x 100 mm, with their length adjustable from 200 to 750 mm. The entire unit measures only 3.3 meters long x 1 meter wide x 2 meters high.

The slightly larger model SB 301 makes briquettes of EPS 100 x 80 mm x 250 mm long, weighing 1500 pcf. The largest model is the SB 3600 for PET bottles, which compacts up to 2400 lb/hr into bales 240 mm wide x 240 mm high and 100 to 700 mm long. Their density is 880 pcf. Over 1000 of these large units have been installed. All briquetter sizes are small enough to fit on a flatbed truck for mobile compacting.

Another way to densify EPS foam is with a new agglomerator from Pla.to GmbH in Koln, Germany (formerly Systec, the machine-building unit of Germany's Duales System or Green Dot recycling initiative). The machine compacts EPS foam from 0.6 pcf to 25 or 28 pcf.

First the EPS is shredded. Then it goes to a feeding box with three paddles and a screw auger at the bottom, which feeds into a 300-mm-diam. compression zone. This produces a compacted cylinder, which is fed between a pair of slightly conical discs, one fixed, the other turning at 300 to 400 rpm.

The stator disc has radiating ridges on its surface, turned at an angle to a perfect radial orientation. The turning disc has similar ridges, angled in the opposite direction. The discs are water-cooled to keep frictional heat down to 5° to 10° C below the plastic melt temperature. Friction and pressure between the discs in a sort of scissors effect softens the log of compacted plastic without melting it. Softened plastic travels outward with centrifugal force, flowing through the channels between the ridges and coming out in long noodle-like shapes, which are transported and cooled by air.

Transport air is separated in a cyclone. The plastic then goes through a shredder and deduster and is screened to 8-, 10-, and 12-mm sizes. The disc compactor comes in four output ranges from 220 to 3000 lb/hr.

Low-volume solid-stater

Starlinger & Co. GmbH in Austria introduced at K 2004 the Recostar recycling extruder, which it calls a first for in-line solid-stating of PET flake. Flake starts in a crystallizing dryer, then goes into an extruder with high vacuum and a pelletizer. After pelletizing, the material goes into a relatively small solid-state polycondensator, or SSP.

The SSP comes in two sizes: 440 and 550 lb/hr. Commercial solid-staters typically have throughputs of thousands of lb/hr and are much too big for in-house scrap reclaim or post-consumer recycling. The first SSP installation was in the U.S. for reclaiming nonwoven scrap.

For commingled plastics

A.R.T. Recycling Technik GmbH in Germany has a low-pressure system for molding pallets from commingled plastics. Model E160SP4 fills molds from a single point with 1000 psi. It uses a 160-mm recycling extruder from Gamma Meccanica SpA in Italy, but could use other brands as well. Capacity is 1700 lb, or 45 standard pallets, per hour.

Sol Plastics in Montreal has 30 of the A.R.T. machines making pallets from a blend of recycled HDPE, LDPE, and PP. FriedolaTech in Thuringen, Germany, also makes pallets with this machine, using a mix of metalized film scrap from candy wrappers. Customers in Austria and Thailand use the system to mold commingled-plastic roof tiles.

Shredder news

Two companies showed new systems that combine shredders with recycling extruders. Erema in Germany showed its new "Double Disc" cutter for the first time. Normally Erema uses a single disc at the bottom of the cutter/compactor feed drum to cut, mix, and densify film before it goes into the extruder. The new version uses two cutting discs, one above the other. The first disc does coarse precutting without adding as much heat as the lower disc. The two-disc system can accept coarser feedstock and operates more smoothly. With PE film, it gets up to 15% higher throughputs, Erema says. The dual-disc configuration can be retrofitted on older units.

NGR Next Generation Recycling Maschinen GmbH in Austria has a new 165-mm-diam. model of its shredder/extruder. Designed to process whole bales, its throughput is 3300 lb/hr—even for hard-to-chop scrap like OPP rafia fiber, according to NGR.

Also targeting tough film waste and synthetic fiber scrap, Vecoplan Maschinenfabrik GmbH in Germany has developed the world's first shredder with a permanent-magnet, synchronous torque motor, which needs no gearbox. Vecoplan has applied for patents on the use of this kind of drive in shredders (it's also starting to appear on extruders).

Vecoplan's HiTorc motor (around 100 to 300 hp) uses a variable-frequency drive and speed encoder to control both speed and direction of rotor movement (reversing the field reverses the direction). The HiTorc motor reportedly provides more torque across a range of rotor speeds from 0 to 350 rpm, whereas a standard asynchronous motor drive has a fixed speed of about 150 rpm.

The HiTorc motor delivers three times the nominal torque on start-up and maintains nominal torque almost up to its maximum speed for much higher overall energy efficiency. The HiTorc has a maximum current draw of 300% of full-load amperage, while conventional motors may draw up to 700% FLA, Vecoplan says. The new motor also starts, stops, and reverses direction in 2 sec "with absolutely no wear to the system," Vecoplan says. vs 12 to 15 sec for a conventional drive, which does experience slip and wear and is also noisier.

The new motor reportedly boosts throughput capacity by 30% to 100% while dramatically cutting the cost of energy and maintenance. In the smaller models, the HiTorc motor option adds 25% to 30% to the machine cost, whereas in the larger sizes the cost difference is negligible. Vecoplan has delivered at least half a dozen machines with the new motor.

Meanwhile, Rapid Granulator AB in Sweden introduced what it says is the first single-shaft shredder designed specifically for plastics. Shredders are typically designed to grind wood scrap and municipal waste. Rapid's new GranuMatic shredder places up to 27 knives on a rotor in a herringbone design and at variable depths, whereas typical wood shredders place the knives straight across the rotor at the same depth. The GranuMatic's Polycut system has a pneumatic radial ram feed and concave scalloped knives that cut plastic into long strips in order to make more uniform chips. Ram pressure is modulated by motor amp draw to prevent blocking.

The new machine comes with feed openings 560, 1100, and 1650 mm wide. Rapid says the more efficient cutting geometry allows use of motors up to 30 hp, vs. 50 to 60 hp for typical wood shredders. The widest model has a 75-hp motor, while comparable standard shredders would use 150 hp.

Weima Maschinenbau GmbH in Germany introduced a new quick screen-removal system for its four-shaft ZM shredders. Previously, screens were bolted in place and took much longer to change. The new ZMK-X quick-change model locks the screen in place with easy-releasing toggles. The screen then drops onto a frame, which slides sideways out of the machine like a trundle bed, allowing easy cleaning and screen changing plus direct access to the cutting chamber. ZMK-X shredders with 25 or 40 hp are designed to grind large hollow parts like bumpers.

Tough grinding

Weima also came out with what it calls the world's largest granulator, the WLK 30 Super-Jumbo, which has a 3-meter-long rotor, half a meter longer than Weima's previous maximum. The WLK 30 has a hopper volume of 9.6 m3 and rotor diam. of 600 mm.

Previero Plastic and Rubber Machinery in Italy, represented here by Common Sense Solutions, introduced a grinder with a quick-change screen. The screen has a movable support, so when the upper discharge door is opened, the screen swings out. The screen then comes off by removing a plate with seven bolts. A mechanical interlock on the rotors makes it impossible to use the main drive when the cutting chamber is open. Instead, a small hydraulic motor turns the rotor at 1 rpm for service purposes.

Hosokawa Polymer Systems in Germany showed a new grinder, which it says is unique in the world for its ability to granulate very tough BOPP film at extremely high rates. Model 90/300 RO, or "T-Rex," has two 300-hp drives and a 36 x 114 in. cutting chamber. It's designed to cut film at up to 1600 ft/min or 13,500 lb/hr. "That's a record. Nobody else comes close," say a company spokesman. Five of these units are in operation. At the show, the smaller Model 80/200CL, had a feed-roll assembly, 300-hp drive, and 31 x 79 in. cutting chamber. Its throughput was up to 2000 ft/min or 4000 lb/hr.

Also new from Hosokawa is a granulator that includes dedusting. There are two such systems in the U.S., including one that continuously grinds 4000 lb/hr of post-consumer and post-industrial PP structural-foam pallets. A beside-the-press model appeared at the show. In these units, flake comes out of a cyclone, goes through a rotary air lock, and discharges into a zig-zag dedusting chamber, which cleans the regrind automatically, collecting dust, fines and paper in a bin.

Process Control Corp. showed its new GFA Series of film edge-trim grinders, said to be the lowest cost units on the market because they use a much smaller motor than most—only 5 hp—sized for the low throughput requirement (60 to 70 lb/hr) of reclaiming edge trim. Typically the smallest edge-trim grinders are over-powered with 10- to 20-hp motors, the company claims.

The GFA has two feed options. For edge-trim alone, it uses one 5-hp blower both as the inducer that leads trim into the grinder and as the fan that blows ground fluff out of the cutter. This configuration costs about half what conventional side feeders cost, Process Control says. If the grinder also has to grind roll scrap, it needs a separate blower for the edge-trim inducer and a 2-hp conveying fan for fluff, but still costs less than conventional units.

Related Content

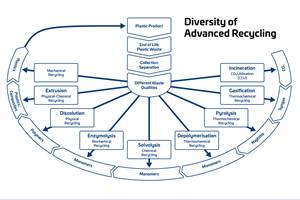

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreInside the Florida Recycler Gearing Up to Take on Scrap at NPE2024

Hundreds of tons of demonstration products will be created at NPE2024 next spring. Commercial Plastics Recycling strives to recycle all of it.

Read MoreSD Polymers: 'One-Stop Solution for Mechanical Recycling'

‘Passionate’ recycler invests in people and technology to meet commitment to innovative, sustainable solutions for its processor customers.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More