Keurig Switches to PP But Has Long Recycling Journey Ahead

After a decade of listening to complaints about the lack of recyclability of its K-Cups, Keurig, Waterbury, Vt., recently announced changes to its packaging but will they be enough for critics?

After a decade of listening to complaints about the lack of recyclability of its K-Cups, Keurig, Waterbury, Vt., recently announced changes to its packaging but will they be enough for critics?

The company will introduce initial coffee varieties in a new recyclable K-Cup pod later this year. Keurig stated it has a goal for 100% of K-Cup pods to be recyclable by 2020.

The material of choice for Keurig is now polypropylene. However, just simply switching to PP isn’t going to automatically solve recycling woes. For one, there’s still some work required of the consumers as the lid and this PP pod has to be peeled away after use and the grounds emptied before the pod. Also, consumers will also have to find out if PP recycling is available in their area. And beyond that, with regards to the facilities that can accept it, reportedly the pods’ small size can impact the automatic sorting and screening equipment at single-stream processing plants.

Keurig says that it is working to solve the challenges of sorting and capturing the K-Cup pods. In a statement, the company noted:

So for some time now we have been working to better understand the current state and trends in the recycling industry and are collaborating with plastics experts and the recycling community to ensure our new recyclable pods can successfully make the journey from home recycling bin to a plastics reclaimer where they can have a second life. This work is critical since the 600+ materials recovery facilities (MRFs) in the U.S. and Canada do not use standardized equipment, resulting in variation in what materials are accepted and how they are sorted.

Keurig is working with Resource Recycling Systems, Ann Arbor, Mich., to run tests in three different U.S. communities. The tests started with thousands of recyclable K-Cup pods in various configurations – white and dark cups, single and stacked cups, and intact and separated cups. The company mixed the cups with about 70 tons of incoming recyclable material at each of the three MRFs, and ran the equipment for about two hours in order to process all 70 tons.

Keurig says that the tests confirmed that the majority of the test pods made it past initial material screens and were available to be properly sorted and processed.

Keurig will conduct more tests to gather additional data. With a goal of optimizing the capture of small PP items, Keurig is using RFID chips affixed to each pod to track exactly where each and every pod goes after entering the MRF.

The company has also joined other consumer goods companies and retailers in the Closed Loop Fund (CLF, New York, NY), a social impact fund investing $100 million to increase the recycling of products and packaging in the U.S. Keurig is investing $5 million over five years to the fund and participating on the Fund’s Advisory Board as an initial investor. Recently, CLF announced the funding and development of a plastics recovery facility in Baltimore, Maryland that will increase #3-7 plastic recovery rates and divert an anticipated 650,000-plus tons from landfills over the next 10 years.

The company also announced it has joined The Recycling Partnership, Arlington, Virginia. To date, The Recycling Partnership’s efforts have directly touched 72 communities representing more than 1.2 million households and counting. The group has leveraged the distribution of 165,000 curbside recycling carts, which are projected to increase the amount of material collected by 251,500 tons – with an economic value of $18 million – over the next decade.

Given that it sold more than 9 billion non-recyclable K-Cups in 2015 alone, it was imperative that Keurig find a recycling solution. But making the switch to PP is just the first step in its long recycling journey.

Related Content

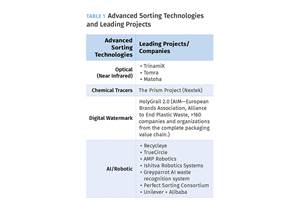

Recycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

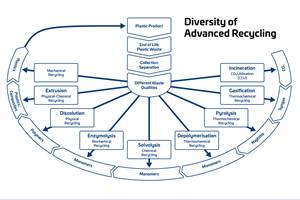

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreCalculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)