MATERIALS: Thermoplastic Urethanes: Why Annealing Makes a Big Difference

Under the right conditions, annealing can drive TPU performance to a greater level than can be achieved at room temperature.

Polyurethanes exhibit an incredible range of chemistries and structures that may be unmatched in the world of polymers. While all polyurethanes are fundamentally the product of a reaction between an isocyanate and an alcohol (polyol), the exact chemistry of these ingredients can be varied significantly to create a wide range of properties. In addition, altering the ratio of what are referred to as the hard and soft blocks within the structure produces different property balances that are typically indicated by surface hardness; beginning as low as 60 on the Shore A scale and extending up to 75 on the Shore D scale.

Polyurethanes can be chemically crosslinked to form thermosets or they can be thermoplastic. And while these materials are generally considered to be elastomers, a family of rigid urethanes known commercially as Isoplast reportedly depolymerize when heated to their melt-processing temperatures and repolymerize when they solidify in the mold … a pretty neat trick beyond the capability of most polymers.

Polyurethane chemistry allows the performance of these materials to be improved when parts molded from TPU are annealed. The properties of as-molded TPU parts are not fully developed, and the maturation process can take weeks if the parts are stored at room temperature. During this maturation process, mechanical and thermal performance improves due to the formation of physical crosslinks.

These do not have the permanence of chemical crosslinks and they can be broken by high temperatures so that the material will still melt. But physical crosslinks enhance performance across a significant temperature range. The rate of formation of physical crosslinks in molded parts is increased through annealing.

While the literature on annealing often suggests that the process simply reduces the time required to achieve an ideal structure, the reality is that annealing under the right conditions can actually drive performance to a greater level than can be achieved at room temperature, regardless of how long you wait. Since even the softest TPUs do not melt until the temperature reaches about 150 C (302 F), the general guidelines for annealing these materials prescribe a temperature of 110 C (230 F) for a period of 16-24 hr. But with harder grades where the onset of melting may not occur until 200 C (392 F), it is possible to employ higher temperatures.

Annealing is performed on different classes of materials for different reasons and is often thought of strictly as a technique for reducing molded-in stress. In traditional thermosets that crosslink through a condensation reaction, such as phenolics and polyimides, the purpose is to increase the degree of crosslinking beyond that which can readily be obtained within the molding cycle. In this instance, it is typically referred to as post-baking or post-curing.

Thermoset parts are often very thick, and the degree of crosslinking in as-molded parts may be different between the part’s surface and its core. Post-baking tends to even out this differential, and in doing so can produce a reduced level of internal stress.

In semi-crystalline thermoplastics, annealing is performed above the glass-transition temperature (Tg) of the polymer to create a higher degree of crystallinity. And in amorphous thermoplastics, annealing is performed at a temperature slightly below the Tg as a stress-reduction technique. For the most part, the object of the exercise is to improve performance at elevated temperatures.

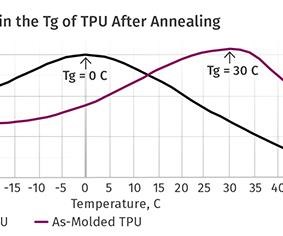

However, in TPU materials, annealing enhances performance at both ends of the temperature spectrum. Annealing has been shown to improve properties at elevated temperatures, but it also enhances low-temperature performance by reducing the Tg of the polymer. The useful temperature range of an elastomer is defined by these two benchmarks. Below the Tg, elastomers become hard and brittle and no longer have the flexibility and damping properties that are required of this class of materials. But as they approach the melting point, the crystal structure that makes up the hard segments of the structure begins to break up and the mechanical properties decline. Annealing has been shown to improve elevated-temperature performance while also reducing the Tg.

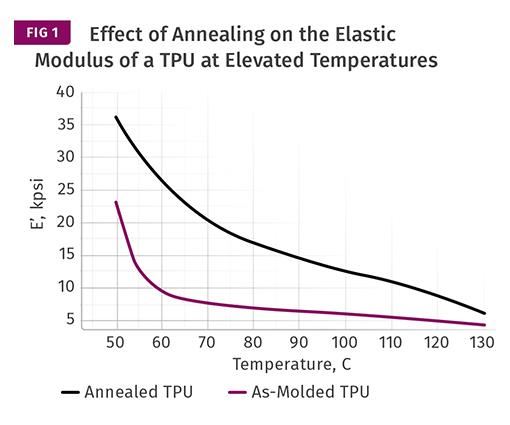

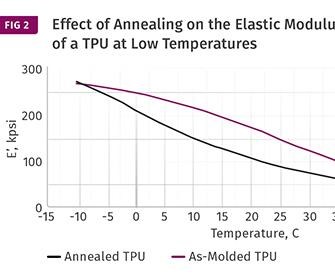

Figure 1 shows a comparison of the elastic modulus of a TPU with a nominal Shore hardness of 70D before and after annealing. The annealing process has increased the modulus of the material above room temperature. This improvement solved a problem with deformation that was occurring in the molded parts during an assembly process conducted at elevated temperatures. At the same time, the annealing process decreased the room-Temperature stiffness of the material, giving it a better “feel” at these conditions and maintaining that softer tactile response down to subambient conditions. This is shown in Fig. 2. A property known as the viscous modulus or loss modulus is used to highlight the glass-transition region and identify the Tg. By convention the Tg is taken as the peak temperature of the loss modulus. Figure 3 shows the comparison of this property for the as-molded and annealed material.

The chemistry and physics behind this transformation are fascinating and a bit beyond the scope of this article. But the practical importance of this type of behavior is difficult to overstate. In this case, the annealing process took a material that was unsuitable for the desired application at both the high-temperature and the low-temperature end of the spectrum and converted it into a product that met all the application requirements. So when evaluating TPUs for application performance, it is beneficial to remember the strategy of annealing.

ABOUT THE AUTHOR

Mike Sepe is an independent, global materials and processing consultant whose company, Michael P. Sepe, LLC, is based in Sedona, Ariz. He has 40 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting, and failure analysis. Contact: (928) 203-0408 • mike@thematerialanalyst.com.

Related Content

Understanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

Read MoreCommodity Resin Prices Flat to Lower

Major price correction looms for PP, and lower prices are projected for PE, PS, PVC and PET.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreNew Entrant Heartland Polymers Stepping up as Reliable Supplier

Heartland Polymers’ new Alberta, Canada facility will produce 525 KTA propylene and 525 KTA polypropylene. It is expected to stabilize supply chains across the continent.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.jpg;width=70;height=70;mode=crop)