Modular Conveyors Help Molder Automate Quality Control

Easily reconfigurable belt conveyors provided one molder a convenient means of 100% QC inspection for tramp metal.

A couple of years ago, JAE Oregon, Tualatin, Ore., a manufacturer of electronic connectors for automotive and telecommunications, was looking for a way to reduce the amount of scrap from its molding operation. Todd McNemee, senior molding manufacturing engineer, designed a cavity separation system that integrated parts conveyors with a metal detector that was already in use. Molded parts slide through channels of UHMWPE. The key to implementing this concept was eliminating cumbersome adaptations needed to integrate conventional conveyors with the metal-detection system. The flexibility of modular conveyors provided the answer.

JAE Oregon, a division of JAE Aviation Electronics Industry Ltd. of Japan, has 32 injection presses of 18 to 130 metric tons. It molds, plates, stamps, and assembles about 15 million PBT connectors per month on a 24/7 basis. Its connector molds can have hundreds of very delicate core pins that can break, contaminating parts with tramp metal and resulting in reject with incorrect pin-hole patterns. This was the key quality issue that McNemee wanted to solve by passing every part through a metal detector and separating parts by cavity to easily segregate any rejects. Parts from each of four cavities end up in separate catch bags. McNemee calls this a “separator belt system,” or SBS.

Some other production lines use a metal detector under the press. The conveyor is stopped once tramp metal is detected so bad parts do not reach the tote, catch bag, or operator station.

“In the past, McNemee says, “We could run all day without detecting a broken core.” Inspection of a full shot of parts at regular intervals now partly alleviates that risk. But, as McNemee notes, one piece of metal debris or one bad part caused by a broken pin would cause an entire tote full or parts to be scrapped. But the new metal detectors and cavity-separation system have reduced the amount of scrap tenfold.

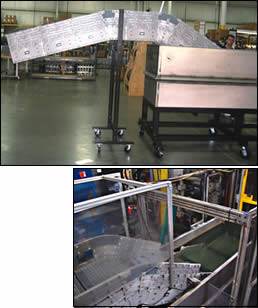

McNemee’s first attempt involved trying to make the firm’s old conveyors work with the new metal-detection system. But in the new layout, the old fixed-length conveyors extended into the walkway, which was unacceptable. McNemee then contacted Dynamic Conveyor Corp., Muskegon, Mich., whose DynaCon line of modular, reconfigurable conveyors facilitate custom configuration and precision adjustment without expensive alterations. Easily interchangeable modules, as short as 6 in., allow users to alter configurations within minutes.

Another significant downfall of the old conveyors, says McNemee, is that “bearings in traditional conveyors tend to fail too often, start to grind, and create a black degraded mixture of metal shavings and grease, which results in product loss.” Additionally, belts on traditional conveyors can get off track over time, resulting in belt fragmentation that mixes with product, which then has to be scrapped. For McNemee, the leanliness of the DynaCon conveyor systems is a major advantage. No lubrication is needed, and the positive sprocket drive with automatic belt tracking eliminates slippage and edge damage of belts.

“We have run the new conveyors for two years now without problems,” says McNemee. “The more old conveyors we replace, the fewer contaminations and complications we have, and that is good for the bottom line.” JAE Oregon now has five SBS systems using DynCon conveyors, and a couple more on the way.

JAE Oregon also uses about a dozen more DynaCon conveyors simply to remove parts from under the press for direct-drop applications. Another five modular conveyor systems are designed to enhance ergonomics at the plant. Where totes were previously filled at floor level, parts are now carried from an under-the-press metal detector via to a carousel bagger or to totes atop workstations using DynaCon Z-style conveyors, which McNemee calls “risers.” He says, “The DynaCon system is an integral piece in our quality-control system, wherever it is used, and really helps with our reject containment.”

Two additional features of DynaCon’s conveyor systems also complement JAE Oregon’s production line. The conveyors have 3/8-in. mounting bolts along the conveyors’ sidewalls, which allow a variety of locations to mount add-on-shields, cooling fans, etc. “Drilling, tapping, and clamping with other manufacturers’ conveyors is a bit more work,” says McNemee.

He also likes the DynaCon models’ variable-speed control. “Other conveyors do have speed control, but I have not found them to be as good. Others would advance and stop and advance and stop. The way we have it set up now allows parts to cool to room temperature by the time they reach operators.

“The DynaCon modular conveyor systems work so well, I am introducing them as replacements for all the older conveyors we have, as quickly as I can.”

Related Content

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreHow to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read MoreRead Next

What to Look for in a Modular, Reconfigurable Conveyor System

As conveyors have become a necessity on the plant floor, conveyor manufacturers have attempted to respond to end-users’ needs for flexibility by creating truly modular, reconfigurable systems.

Read MoreCustom Conveying Systems Pay Big Returns for Molders

Two injection molders of very different kinds of parts recently faced production problems related to inefficient conveying systems.

Read MoreModular Conveyor Boosts Productivity and Profits for Toothbrush Manufacturer

Automation in plastics processing can involve sophisticated, high-tech manufacturing cells specialized for a particular application (see NPE feature this month ). Or it can involve much simpler, off-the-shelf solutions that offer the user flexibility to configure—and reconfigure—an automation system according to the job and plant layout.

Read More