Molders Try Cross-Training To Build Crucial Skills In-House

Processor Strategies

Despite high unemployment, many plastics processors still can’t find qualified workers to fill open positions that require specialized skills. So some are looking at further developing the skills of the employees they already have.

One of the major challenges facing American manufacturers is what some have referred to as the “skills gap.” Despite lingering high unemployment, many plastics processors still can’t find qualified workers to fill open positions that require specialized skills. In an effort to solve this significant problem, some processors are looking at further developing the skills of the employees they already have.

Thermo Fisher Scientific, a supplier of laboratory instruments and supplies, is one processor that’s implementing such a cross-training program. In late 2011, the company began deploying a custom program from Routsis Training, a plastics training specialist, for workers at its injection molding plant in Petaluma, Calif.

As part of the company’s Liquid Handling and Consumables business, the Thermo Fisher plant employs 140 people and manufactures disposable pipette tips, tubes, and other supplies used in laboratory research. Operations include part production and manufacturing support, tooling, maintenance, packaging, and warehousing.

Thermo Fisher is in the process of introducing the training program to the first 25 to 30 molding machine operators, said Ira Burks, human resource manager for West Coast operations. “Over time, we lose molders to retirement or industry change. One recent retiree had 25 to 30 years of molding experience,” Burks said. “It can be a challenge to find suitable replacements. So we began looking at ways to maintain our workforce.”

Thermo Fisher’s training program in Petaluma is designed to provide all machine operators with the same skills covering the diversity of machines at the plant. There are more than 200 presses in Petaluma, including proprietary equipment running high-cavitation tooling with complex operator interfaces.

Says Burks. “In the short term, our aim is for all of our operators to be at the same level of knowledge and experience across machines. This eliminates any issues when someone is out sick or on vacation, since others will be cross trained and comfortable working on all of the machines.”

The training program is set up for basic molding all the way through to advanced processing, covering part and mold design, hydraulics, geometric dimensioning and tolerancing, and several other areas. Using Routsis’ online training courses, employees learn at their own pace, reinforced by hands-on training in the plant.

Burks says Petaluma is working toward expanding training across the plant so that it can move other employees into molding technician positions. Long term, the company’s goals include lower scrap rates, reduced mold damage, and increased first-pass yield.

Many of those goals are shared by SL Tennessee LLC, a South Korean-owned auto parts maker in Clinton, Tenn., which also recently implemented a Routsis training program. SL Tennessee is training mold technicians, supervisors, and tooling and maintenance personnel with a mix of hands-on, classroom, on-the-job, and online courses. The program covers molding basics, blueprint reading, material drying, mold maintenance, mold setup, decoupled molding, and more. Employees verify that they’re retaining and using the skills they’ve learned through worksheets used on the floor.

Like Thermo Fischer Scientific, SL Tennessee is looking to use the training to develop molding technicians from within its plant. In the process, the company has achieved immediate performance benefits since launching its training program in late October 2011.

“We have a large number of new technicians, and the training is helping them advance their startup skills, which lowers our scrap rates,” states Mike Ballew, processing engineer. Adds Linda Bass, training coordinator, “Cycle time and downtime have gotten a lot better, too. The broader, more consistent knowledge on the floor has benefited us a lot

Related Content

Paulson Training Acquired

Certus, a technical skills training business and portfolio company of private equity firm Ridgemont Equity Partners, has acquired the plastics processing training business founded in 1981.

Read MorePlastics Processors Who Hire ‘Second-Chance’ Workers Do Well by Doing Good

Two blow molders with long-standing programs of hiring formerly incarcerated low-level offenders have helped these individuals re-enter their communities and have benefited from an additional resource during chronic labor shortages.

Read MoreEducational Grant and Student Scholarships Open

The Society of Plastics Engineers’ Mold Technologies division is accepting applications for a $5,000 educational grant and a new $3,000 student scholarship honoring Glenn Beall.

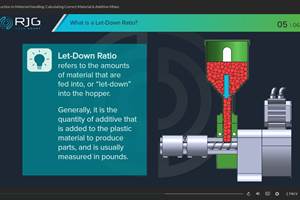

Read MoreLearn Fundamentals of Materials Handling in Self-Paced Online Course

Learn about equipment, procedures and maintenance for material handling related to injection molding.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More