New 3D Printers at NYC Show

Affordability, speed, and improved mechanical properties appeal to early adopters.

At least three new models of 3D printers were on display at the Design & Manufacturing Atlantic show in June at the Jacob J. Javits Convention Center in NYC. Some early adopters of new additive manufacturing (AM) technologies were also at the show.

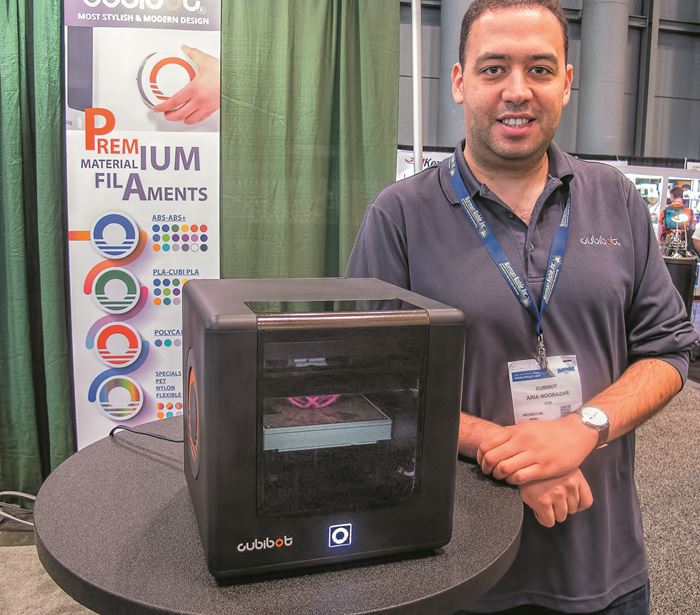

SMALL, AFFORDABLE FDM PRINTER

A new FDM-type 3D printer from Cubibot, a San Diego-based startup, is described as one of the smallest printers on the market, “super-affordable,” and easy to use. It offers a 5-in. cubed print envelope within a 10-in. cubed footprint for the device. The refillable filament cartridge can run ABS, PLA, PC, and nylon materials. It’s expected to cost under $500 when it starts shipping in the next few months. (A kickstarter campaign is now underway.)

Despite its small size and price tag, the Cubibot is feature-loaded, according to Aria Noorazar, CEO/CTO. Not least is its precision, down to 0.1 mm. Unlike some other units, it also comes with a heated print bed as standard, and filtered ventilation for safer use. The printer is wi-fi enabled and operated with web-based software. Remote control is available via Android and iOS apps.

FDM printing now comes in a highly compact, “super-affordable” package.

LARGER CONTINUOUS PRINTER

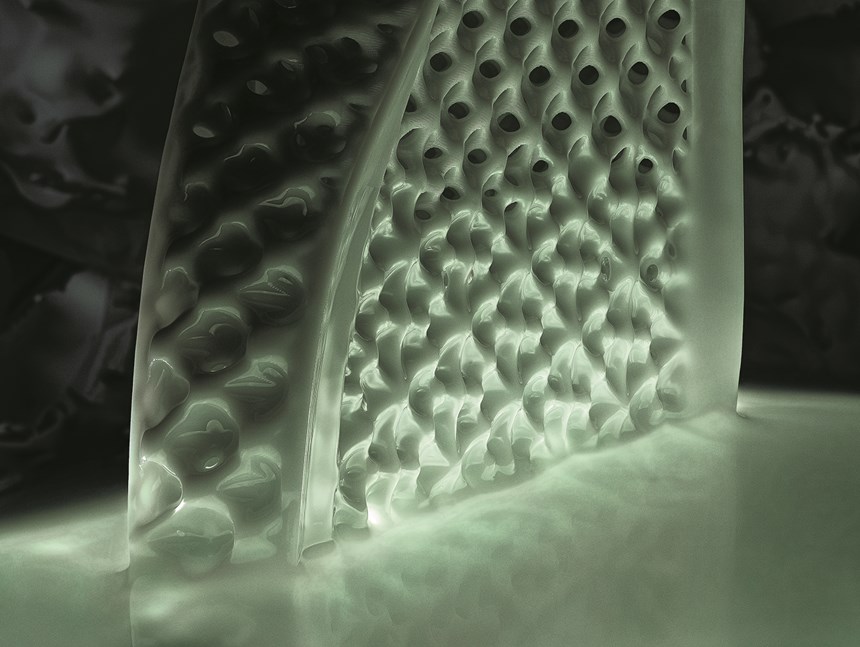

A “game-changing” 3D printer that reportedly makes parts 25 to 100 times faster than any other additive manufacturing system is now available in a second, larger model. As

reported in our Nov. ’15 Close Up, the printer from Carbon3D, Inc., Redwood City, Calif., is unlike any other in that it does not print layer by layer, but continuously pulls a part upward from a pool of liquid photo-polymer that is solidified by UV light.

This reportedly yields isotropic properties more similar to those of injection molded parts. Also unlike other AM methods, which add layers to the top of the part, Carbon’s CLIP (Continuous Liquid Interface Production) technology (also known as DLS—Digital Light Synthesis) pulls the part upward from the liquid pool while curing at the bottom of the growing part. The pulling or “growing” speed varies automatically according to the cross-section of the part (faster where the part is thinner, slower where it is thicker). Compared with other AM systems, initial production time is said to be reduced from hours to minutes. However, the “green” parts require post-curing in a forced-air circulation oven to develop their full mechanical properties by a second chemical reaction.

Carbon introduced its first CLIP printer, the M1, in April 2016. It has a build volume of 5.6 × 3.1 × 12.8 in. (141 × 79 × 326 mm) and a pixel resolution of 75 μm. Now there is also the model M2 with twice the build volume but the same resolution. Also new is a Smart Part Washer as a separate unit.

Carbon3D has implemented a subscription pricing model, whereby an M2 printer costs $50,000/yr for a minimum term of 3 yrs. The M1 costs $40,000/yr. That includes current software and free updates, plus phone and email support and on-site service for repair and maintenance. Additional one-time expenses are a $5000 installation and training fee, and an “Accessory Pack” for $12,500 that includes the resin dispensing unit, UV lamp, and curing oven. The new Part Washer costs $10,000/yr (3-yr minimum) plus a $5000 installation fee.

Carbon3D has also expanded its range of liquid resins to include three grades of rigid urethanes, a flexible PUR, an elastomeric PUR, a cyanate ester with high heat resistance (HDT up to 219 C/426 F), an epoxy with properties resembling 20% glass-filled PBT (HDT of 140 C/284 F), a urethane methacrylate for making jigs and fixtures (properties similar to SLA resins), and a dental grade.

Also new this past spring is the first commercial application of CLIP technology, Futurecraft 4D running shoes from adidas. Using AM to make the lattice-design midsole allows personalization of each pair of shoes. More than 5000 pairs will be offered for retail this fall and winter, and more than 100,000 pairs are expected to be sold by the end of next year.

Novel continuous 3D printing process is now available with a larger build volume, achieves first commercial use.

Shortly after the adidas announcement, Carbon3D reported that Oracle Labs, the R&D arm of computer technology firm Oracle, commissioned printing of 10,000 server mounts (brackets for circuit boards) of Carbon’s rigid PUR. Injection molding was rejected as unable to provide the parts in a timely manner, while conventional 3D printing did not satisfy Oracle Labs’ performance requirements. One of Carbon’s first service-bureau partners, Sculpteo (locations in Paris and San Francisco), produced the brackets in days rather than months. Instead of printing the parts one at a time, Sculpteo produced a large cube of interconnected brackets.

Also at the NYC show was one of Carbon’s newest service bureaus, Dinsmore Inc., Irvine, Calif. Dinsmore recently added M1 and M2 CLIP printers to its roster of rapid-prototyping technologies—SLA, SLS, FDM, PolyJet, DMLS (direct metal laser sintering), plastic casting, and CNC milling. It also offers injection molding services though an outside partner.

Another new CLIP service bureau is Midwest Prototyping, Blue Mounds, Wis. This firm also offers SLA, SLS, FDM, PolyJet, binder jetting, PUR casting, and CNC machining.

LASER SINTERING UPGRADE

At the NYC show, EOS of North America, Inc., Novi, Mich., discussed its new EOS P 770 laser-sintering machine for thermoplastics like nylon 12, PEEK, and PEBA elastomer (a TPU is in the works). This high-capacity, dual-laser system is 20% more productive than its P 760 predecessor. Its large build volume (27.6 × 15 × 22.9 in. or 700 × 380 × 580 mm) allows production of parts up to 1 meter long.

QUICK-TURN SPECIALIST ADDS NEW PROCESS

Proto Labs, Inc., Maple Plain, Minn., a specialist in quick-turn prototyping and short-run manufacturing, announced at the show a new addition to its stable of prototyping technologies. Proto Labs announced it is now offering the Multi Jet Fusion process of HP Inc., Palo Alto, Calif., for production of fully functional plastic prototypes and production parts. Proto Labs already offers SLA, SLS, PolyJet, and direct metal laser sintering (DMLS), as well as CNC machining and injection molding. The firm served as a beta tester for the Multi Jet Fusion (MJF) process, which was first unveiled by HP in 2014 and became commercially available this May.

Questions About 3D Printing? Visit Our Additive Manufacturing Zone

The process builds up a part layer by layer. It involves inkjet spraying a digital pattern of droplets of fusing and “detailing” agents onto a bed of nylon 12 powder, followed by thermal fusion of the printed area. HP says MJF is up to 10 times faster than SLS and FDM processes. It deposits up to 30 million droplets per second per inch of working area, and it fuses the entire working layer at once, unlike most other processes. Proto Labs applications engineer Joe Cretella agrees that MJF is faster than other nylon-powder based 3D printing technologies and it also produces finer details, more isotropic properties, tighter tolerances, and smoother surfaces. As a result, MJF reportedly could compete with injection molding in some cases for volumes in the range of thousands of parts.

Related Content

Business Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read MoreHow Additive Manufacturing Can Help, not Hinder, Injection Moldability of New Designs

Four cost drivers—design for moldability, mold-base size, internal componentry, polish/custom finishing—dictate the financial and processing success of a molded part design. Learn how 3D printing can assist this process, while also understanding its potential pitfalls.

Read MoreFreeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)