New Group Gets Continuous-Fiber-Reinforced Composites Ready

New team to support partners though all stages of Tepex component development.

New team to support partners though all stages of Tepex component development.

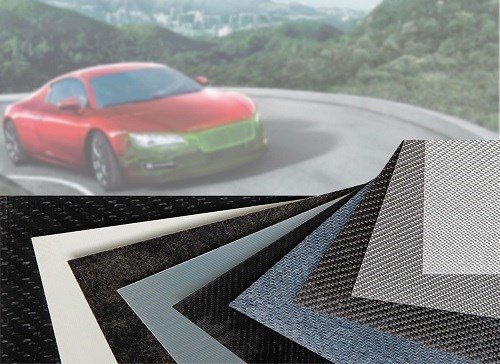

Since Lanxess (U.S. office in Pittsburgh) acquired Bond-Laminates four years ago, the company has been ‘nurturing’ and further expanding the Tepex range of continuous-fiber-reinforced thermoplastic semi-finished composites for lightweight construction of automotive components.

And, the company is now further zeroing in on the automotive industry through the formation of a project group that is geared to its needs and support of partners through all stages of Tepex component development right up to production launch. Moreover, by K 2016 in October, the company will have published a brochure on Tepex processing.

It comes as no surprise to us—this increasing thirst for thermoplastic composites in automotive and beyond—as we witnessed full attendance, at each of the 22 presentations of our second “Thermoplastic Composites Conference for Automotive” (TCC Auto2016) which covered topics in Applications & Materials and Machinery & Processes. It took place just last month in Novi, Mich., occurring concurrently with the Amerimold 2016 show and conference, and presented by Plastics Technology magazine and Composites World, sister publications within Gardner Business Media.

So, Lanxess’s new group—Tepex Automotive Technical Marketing & Business Development—essentially brings together the expertise of Lanxess and its subsidiary Bond-Laminates in materials, processes, and the selection of suitable components for automotive lightweight construction with Tepex. This team will act as an interface between CAD concepts, component/process design and simulation, the mold makers and the equipment manufacturers for processing and handling Tepex.

“Our expertise and services are available locally all over the world thanks to the global network of regional product and application development centers that Lanxess has established. We can therefore assist international development partners at all their locations, with everything from first application idea to starting up large-scale production.” Said Martin Klocke, head of the group in the High Performance Materials (HPM) business unit.

Comprehensive processing information on Tepex and the way it works is also underway. Lanxess will showcase this processing guide and K 2016. It will provide information on the advantages of the thermoplastic composite, its potential in lightweight construction and the product families, and will cover in detail the many methods for processing Tepex—such as thermoforming and hybrid molding.

Extensive sections will address techniques for heating Tepex as well as the design and calculation of components for draping and integrative simulation. It will include recommendations on mold design and how to handle hot Tepex inserts. A final section will offer tips on finishing, joining and recycling Tepex components. The brochure is both directed at engineers as well as readers interested in the technology who work, for instance, in marketing or purchasing.

The range of applications where Tepex is being applied has broadened significantly. Initially, it was used to locally reinforce plastic areas in front-ends. By now, it is used to manufacture seat shells, back seats, back rests, brake pedals, battery carriers, infotainment brackets and underbody panels. Just recently, the world’s first, hybrid-molded rear bumper beam went into production for the Honda’s new Clarity Fuel Cell car.

Moreover, the product range continues to expand as we have been reporting since the acquisition. The latest example is multiaxial Tepex, designed to enhance the mechanical performance of components, because the orientation of the reinforcing fiber layers can be adapted to the flow of forces in a component and thus to stress scenarios, according to Klocke. This new structural material is production-ready and will soon be introduced to the market in the first application.

Related Content

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreLanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreCommodity Resin Prices Flat to Lower

Major price correction looms for PP, and lower prices are projected for PE, PS, PVC and PET.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)