New Materials Rise to the DVD Challenge

DVDs are casting a new light on optical discs--quite literally, since new generations of high-density disc players are expected to use blue-green lasers with shorter wavelengths in order to read the smaller pits of new higher-density data discs.

DVDs are casting a new light on optical discs--quite literally, since new generations of high-density disc players are expected to use blue-green lasers with shorter wavelengths in order to read the smaller pits of new higher-density data discs. (Current disc players use longer-wavelength red lasers.) The need for resins with higher transparency in this region of the spectrum, as well as higher flow, greater cleanliness, and reduced birefringence, is driving development of new generations of disc-molding materials. These include not just polycarbonates, but also acrylics and more exotic cyclo-olefins.

Materials developments were prominent at June's Replitech show in San Francisco. Also notable was new software to analyze the interaction of material, mold, and machine to yield the highest disc quality in the shortest cycle time.

New high-flow PCs

Three new or improved polycarbonate resins for optical discs were introduced by GE Plastics, Pittsfield, Mass. New Lexan OQ1040L resin is designed for DVD molders who need a higher-flow grade. GE says this "ultra-low-viscosity" resin will be priced at a premium over other optical-disc grades. Its MFR is 14 in GE's tests at 250 C. Other PC suppliers say that probably translates into more than 80 MFR at the more traditional test temperature of 300 C (ASTM Condition "O"). GE says flow testing is more reliable at the lower temperature.

Also new from GE is Lexan OQ1050, which is available only in Europe and Asia until next year, when it will be offered globally. It is the first optical-quality resin produced at GE's plant in Cartagena, Spain. That plant uses a continuous melt-polymerization process that is said to provide exceptional quality and consistency. (GE's only other plant to use the process is in Chiba, Japan.) Its MFR of about 13 would translate into 75-80 MFR under traditional test conditions, according to other PC producers.

Also, GE says it has improved the quality of its existing Lexan OQ1030L grade (13 MFR) by reducing particulate levels and improving viscosity consistency.

Acrylics contend for DVDs

Two suppliers introduced new acrylic resins specially formulated for DVDs. The Atoglas Div. of Elf Atochem North America Inc., Philadelphia, introduced Plexiglas VOD-100. According to market development manager Don Hone, it offers processing and performance advantages over polycarbonate, as well as lower cost. These include lower viscosity, less birefringence, higher light transmission (especially in the blue-green wavelengths), and greater scratch resistance. In particular, Hone says disc replicators find it simpler to balance cycle speed against birefringence, disc flatness, and signal quality. With PC, improvements in one typically come at the expense of one of the others. "By switching to Plexiglas acrylic resin, replicators remove birefringence from the processing equation," he states. "Acrylic birefringence measures less than 20 nanometers, well below the 60-80 nm exhibited by polycarbonate." Acrylic also costs about 20% less.

Another new acrylic for DVDs is Acrylite DQ501 from CYRO Industries, Rockaway, N.J.

PC suppliers acknowledge the low birefringence of acrylic but question whether it has adequate toughness, heat resistance, or adhesion to sputtered aluminum under DVD end-use conditions. Don Hone, Atoglas market-development manager, says heat resistance is not an issue, since acrylic passes standard environmental cycling tests for DVDs. He adds that sputtering process conditions can be tailored for either high or low adhesion to acrylic, giving it an advantage over PC in some advanced DVD-making processes (see sidebar). He concedes that acrylic's lower toughness could be of concern with regard to hub stresses imposed by some DVD packaging. He says this could be alleviated by modifying today's "jewel-box" package design or reinforcing the disc hub.

'Peachy' trials

Dow Plastics, Midland, Mich., recently conducted DVD molding trials of its developmental PCHE resin at the Disc Technology Center of Axxicon Moulds in Eindhoven, Netherlands. Bonding and metallizing on a DVD production line at Advanced Optical Disc in Vianen, Netherlands, resulted in playable DVDs, Dow reports.

PCHE (known familiarly as "Peachy") stands for polycyclohexylethylene, a saturated cyclic hydrocarbon that is derived from styrene monomer. It is said to have exceptional optical purity and clarity, with a refractive index of 1.51 and high light transmittance across the full spectrum--including the blue-green range.

PCHE also boasts low density (0.94 g/cc) and very low moisture absorption (less than 0.01%), an important factor in maintaining disc flatness. It also does not need drying before molding. High stiffness of PCHE (325,000 psi flexural modulus) will enable discs to withstand faster acceleration and deceleration spin rates on next-generation disc players, Dow claims. PCHE is being sampled selectively to developers of future high-density disc formats.

Describing the recent molding trials, Axxicon development and engineering manager Merijn Voets says, "The new discs were extremely flat with good pit replication, and they exhibited virtually no birefringence. The replication of DVD features was excellent." PCHE demonstrated that it could be molded at moderate temperatures--572-608 F for the melt and 122-140 F for the mold.

Software optimizes set-up

GE drew a lot of attention at Replitech with its new process-analysis software for optical-disc molders. Developed by GE Plastics and GE Corporate R&D in Schenectady, N.Y., the software helps molders evaluate "what-if" processing scenarios to understand the relationships between processing conditions and product quality.

The software is only for GE's use. A GE Plastics technical development engineer uses it in consultation with a customer to input the product specifications, process limits, and type of equipment and materials to be used. Then the software produces a process-capability analysis that graphically illustrates predictions of multiple processing/quality relationships. From this, the GE engineer and customer can derive a process set-up that will optimize yield and cycle time. The software similarly analyzes the bonding and metallization steps.

GE has programmed the software with 15 combinations of molds, machines, and materials used in the marketplace. GE is working with a handful of major disc replicators to expand the database. The software also helps a molder customize the database to its particular mold, machine, and material by suggesting efficient DOE (design of experiments) routines. The software then quickly analyzes the molder's DOE results to show what variables have the most effect on those specs that are most important to disc quality.

Labs get DVD lines

While all three U.S. polycarbonate suppliers have presses outfitted to mold DVDs, they are now considering installing more or less complete DVD replicating lines. In fact, this month GE Plastics plans to finish installing a DVD replicating cell at its new Optical Media Development Center (OMDC) in Pittsfield. The cell will have two 50-ton "Disco" all-electric disc-molding presses from Ferromatik Milacron Integrated Processing Systems, Cincinnati, a new Milacron business unit established late last year.

The Disco machines at the OMDC are integrated with a DVD production line from Steag/First Light and molds from ICT Axxicon. John O'Sullivan, OMDC program leader, says, "We'll be exploring clamp-positioning control for coining, which is thought to be critical to molding a flat, stress-free DVD. With simple control settings that offer repeatability of ±0.01 mm, the all-electric machine will help because it eliminates mechanical settings and other variables that are inherent to coining with hydraulic machines."

Introduced last year, Milacron's Disco machine is a dedicated optical-disc press with a short-stroke toggle clamp and no ejector. Dry-cycle time is just 0.63 sec, up to 10% faster than hydraulic machines, Milacron says. Its noise level reportedly is just 65 dbA and it uses less than half as much energy as a comparable hydraulic machine. Although GE has the first Disco machines in the U.S., several are producing CDs and DVDs in Europe.

Meanwhile, Bayer Corp. in Pittsburgh is planning to acquire a replication cell for DVDs (5, 9, and 10) with two presses plus downstream finishing and testing equipment. Bayer currently has a stand-alone 80-ton Krauss-Maffei press with DVD molding ability.

Higher Capacity DVDs Enter Production

This month, Warner Advanced Media Operations (WAMO) in Olyphant, Pa., is expected to become the first producer of higher-capacity DVD-14 and DVD-18 discs. Whereas current discs hold a maximum of around 10 gigabytes, DVD-14 and 18 will offer close to 14 and 18 gigabytes, respectively. A single-sided, dual-layer DVD-9 disc is bonded together with a single-sided, single-layer DVD-5 disc to make a DVD-14. Or two DVD-9s are combined to make a DVD-18, which can play up to 8 hr of high-quality video.

Creation of a DVD-18 requires two modified DVD-9s that are 0.6 mm thick, rather than the usual 1.2-mm. WAMO accomplishes this with its proprietary Surface Transfer Process (STP). It starts with the normal mastering process to produce the "layer 0" disc in PC, which is then metallized with gold. The information surface for the second layer is molded in acrylic instead of PC. The acrylic layer is only a temporary information carrier that is stripped away after transferring the information surface to the adhesive used to bond the two half-discs together.

WAMO and Marubeni Disc Systems of Southfield, Mich., have formed a technical alliance with Meiki of Japan, Balzers Process Systems, Origin Electric, Basler Vision Technologies, and Dainippon Ink & Chemicals to build a production line that can handle all DVD formats. Marubeni offers such systems for sale to WAMO licensees. One licensee is Nimbus CD International, Inc., Charlottesville, Va., which expects to begin producing DVD-18s by the end of the summer.

Related Content

Prices of Volume Resins Drop

Price relief is expected to continue through the fourth quarter for nine major commodity and engineering resins, driven by widespread supply/demand imbalances.

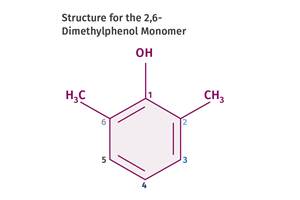

Read MoreTracing the History of Polymeric Materials: Polyphenylene Oxide

Behind the scenes of the discovery of PPO.

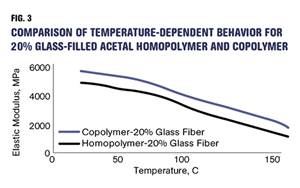

Read MoreHow Do You Like Your Acetal: Homopolymer or Copolymer?

Acetal materials have been a commercial option for more than 50 years.

Read MoreThe Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)