New Molds, Materials and Machines At Fall Rotomolders’ Show

Huge new shuttle and carousel machines, expanded availability of CNC-machined aluminum molds, and new resins and additives highlighted the recent Rotoplas ’08 exhibition and 33rd Annual Fall Meeting of the Association of Rotational Molders (ARM) in Rosemont, Ill.

Huge new shuttle and carousel machines, expanded availability of CNC-machined aluminum molds, and new resins and additives highlighted the recent Rotoplas ’08 exhibition and 33rd Annual Fall Meeting of the Association of Rotational Molders (ARM) in Rosemont, Ill. The event also saw the commercial debut of the first collapsible plastic container for portable storage and moving.

GIANT MACHINES DEBUT

Ferry Industries introduced the Rotospeed RS6000 independent-arm machine, claimed to be the world’s largest carousel machine. It comes in both straight and offset arm styles with a swing from 218 to 239 in. Arm capacity ranges from 10,000 lb for straight-arm designs to 6500 lb for offset arms. The new model is for large parts such as marine products and oil storage tanks. One example is a 20-ft-long marine flotation device from Hydroplast Marine Group, Claremore, Okla.

Ferry also expanded its in-line shuttle series with the M-5500, a dual-arm unit that offers flexible production for short and long cycles. It is offered with straight or offset arms and a swing from 190 to 218 in. Arm capacity is 5000 to 7500 lb. The modular unit shares a single oven and each arm has its own processing cycle. Applications include boats, docks, and storage tanks.

Very large parts can be made on the new RR7030 rock-and-roll machine from Rotoline Industrial Equipment Ltda. of Brazil, represented here by Reduction Engineering. The two-station shuttle machine can make boats and tanks up to 10,000 gal. Its 7-meter-long, 3-m-diam. cylindrical convection oven reportedly minimizes air volume to shorten the heating cycle and reduce energy consumption.

MORE CNC-MACHINED MOLDS

Italian machine and mold builder Persico S.p.A. will open a sales office in Ohio next year, offering CNC-machined aluminum molds as an alternative to cast aluminum. The company has witnessed strong demand in Europe in recent years and sees similar opportunities in North America, according to Sergio Zilioli, sales manager. CNC-machined rotational molds reportedly have seen limited use in the U.S., mainly for small parts.

Persico currently produces about 1200 molds/yr, around 60% of which are CNC machined. Better quality and shorter delivery times are driving demand, according to Zilioli. Other claimed advantages include tighter tolerances, improved surface finish, and reduced mold warpage. Lower mold maintenance is said to yield overall cost reduction of up to 10%.

Persico also announced a distribution agreement whereby Ferry Industries will sell Persico’s Leonardo series of “ovenless” automated rotomolding machines in the U.S. These carousel-type, single-station units use machined aluminum molds with integral heating and cooling. Electrical wires in the mold provide six heat zones. Four machines have been sold in the U.S.

HIGHER-PERFORMING RESINS

ExxonMobil Chemical introduced LLDPE grade LL8450.32 with improved low-temperature impact strength and a broader processing window. It is a 5-MI hexene copolymer with 0.937 density. It is said to provide excellent stiffness and whiteness and low warpage and ESCR, along with improved weatherability for applications such as point-of-purchase-displays, junction boxes, and potable water tanks.

A new series of Rotoloy HDPE compounds from Jerico Plastic Industries combines stiffness, low-temperature impact, and dimensional stability in densities from 0.940 to 0.955. The UV-stabilized grades offer 60 to 80 ft-lb impact at -40 F. Thinner walls are said to be possible in marine, medical, and other applications.

Arkema has commercialized a one-shot version of its PetroSeal two-layer barrier system for rotomolded small-engine fuel tanks. Because of its effective barrier performance, users of this approach are said to be exempted by the California Air Resources Board (CARB) from costly fuel-permeation testing. The one-shot process eliminates a drop box and potentially reduces cycle time. The metallocene MDPE outer layer melts and fuses first, at around 120 C (250 F), while the nylon 11 inner layer melts at about 400 F.

BASF is offering its oligomeric HALS UV stabilizer for the first time for rotomolded PE applications. Uvinul 5050 H has received FDA approval for containers, tanks, and toys. It has excellent compatibility with polyolefins and offers low basicity so there is less chance of chemical interaction.

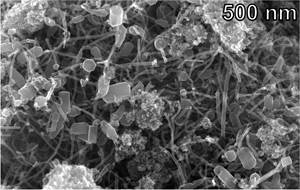

New HDPE powders from ICO Polymers are plasma treated for enhanced adhesion to PUR foam. This is one of the first commercial resin products to use the new RTS plasma treatment system from Lectro Engineering Co. In rotomolded parts, the treated HDPE powder requires 150 to 180 ft-lb of pull force to separate the HDPE from PUR foam, and the foam tears before the PE/PUR interface fails. Lectro Engineering’s open-air plasma-discharge system uses different gas mixtures to treat the surface of pellets or powder.

NOVEL CONTAINER DESIGN

The industry’s first plastic collapsible container for the portable storage and moving market will go commercial next year, according to developers Nova Chemicals and Plasticraft Corp., a rotomolder in Darien, Wis. The 815-lb, 8 x 5 x 8 ft Cosmo container, made of Nova’s Surpass RMs341 HDPE, replaces wood and metal boxes for fixed storage and interstate moving. The design incorporates 12 large twin-wall rotomolded panels that can carry a 2000-lb load. It provides 250 cu ft of storage space and collapses to less than one-third of its height when empty. The container can be erected by one person with a forklift and no hand tools in less than 5 min. Military use is being explored. A verbal agreement has been reached with a major moving and relocation company for the first 1000 containers. A network of molders will be established when the business ramps up.

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More