New PLA Molder Anticipates Swift Growth

SelfEco developed two diverse PLA product lines in less than a year.

SelfEco is a start-up molder that has hit the ground running. The new firm was created by family-owned sister company VistaTek LLC less than a year ago, when the latter recognized the value of molding products from plant-based plastics.

As both a moldmaker and molder, VistaTek already had a couple of years’ experience developing molds and proprietary processing parameters for PLA biopolymer, explains Danny Mishek, president of SelfEco and managing director of VistaTek, both in Stillwater, Minn. He and his younger siblings, Al Mishek, account manager for VistaTek; and Jenny Sutherland, VistaTek’s director of finance, envisioned that the new enterprise would help offset the highs and lows of the moldmaking and injection molding business.

Today, SelfEco shares a 50,000 ft² facility with VistaTek, with 6000 ft² currently dedicated to SelfEco’s conference room, product development, and warehousing. It produces most of its products on VistaTek’s 165- to 220-ton injection presses.

Danny Mishek says it took the new company less than three months to do its product development, product branding, pre-production, and patent filing. But getting compostable certification from the Biodegradable Products Institute (BPI) took nearly six months. SelfEco has several patents pending and more than 30 part numbers within the two product lines it has been developing.

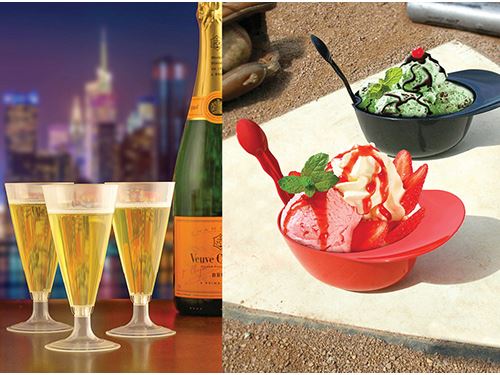

A “party and catering” line, made with food-grade PLA from Natureworks LLC, Minnetonka, Minn., includes food-service items ranging from plates, bowls, cups, and cutlery to champagne flutes and Asian spoons. These are higher-end products that have been sold initially to caterers and private venues. But retail opportunities beckon.

Ditto for the “home and garden” line, which includes various sizes of self-feeding plantable pots and self-feeding sleeves that are made of PLA and a protein nutrient additive. The home-and-garden products decompose during the growing season. Mishek points out that conventional fabric or peat-moss containers, which are meant to decompose, are not as stable for growers when using automated planting systems. Nor do these products supply nutrients to the plants, he notes.

Before developing the home-and-garden line, SelfEco interviewed gardeners and growers. Two topics of concern kept cropping up: fertilizer runoff getting into waterways and the waste of petroleum-based plastic containers going into landfills. Because the nutrients are in the plant-based polymer and underground, the self-feeding pots and sleeves reduce fertilizer runoff.

“Since these pots are plant-based and designed to break down while feeding the plants, this will lessen the stress of traditional petroleum-based plastic pots ending up in the landfill. These products have confronted and resolved the two major issues that concerned today’s gardeners and growers,” says Mishek.

The environmental benefit of SelfEco’s products strikes a chord with both growers and caterers, according to Mishek. He also points out that SelfEco is very cost-competitive with both HDPE- and PLA-based Asian imported food-service items.

Mishek is encouraged by ongoing discussions with such giants as Walmart, Menards, and other retailers: “We’ll be looking at expansion plans in the near future.”

Related Content

-

Compatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

-

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

-

Recycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

.png;maxWidth=300;quality=90)