No. 28 - Multi-Material Injection

Injection molding of two or more materials or colors—or the same material in foam/solid or virgin/ regrind combinations—offers a wide range of opportunities to use materials more cost-effectively and/or combine materials for optimum functionality without the added cost of secondary assembly operations.

Injection molding of two or more materials or colors—or the same material in foam/solid or virgin/ regrind combinations—offers a wide range of opportunities to use materials more cost-effectively and/or combine materials for optimum functionality without the added cost of secondary assembly operations. Today’s broad variety of “soft-touch” hand grips on everything from tool handles to kitchen utensils, toothbrushes, and auto interior control knobs would not be possible without the development of hard/soft overmolding.

The technique is also seeing growing importance in automotive and industrial parts with integral seals. That concept extends to thermoplastic/thermoset molding, in which a silicone rubber seal is molded onto a thermoplastic such as nylon, using the residual heat in the thermoplastic to help cure the silicone. An early example of such molding was demonstrated by Nissei at a 1988 plastics fair in Osaka, Japan.

Multi-component molding also spawned a revolution in tooling design, with the development of rotary platens and molds with turning center stacks.

Arburg built its first machine for automated molding of a prototype two-color typewriter key in 1961. That was followed by a rotary telephone dial in 1962, using a rotating platen. Molded-in characters on keys and dials were more durable than printed ones.

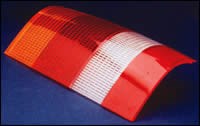

The first known patent for multi-material molding was granted to G. Carozzo in 1962 and was designed to produce objects such as automotive taillights with differing colors. The overmolding technique was patented in 1980 by Jules M. Hock and Donald S. de Vries. It was first used to produce a piston with a rigid core and an integral flexible seal.

Co-injection molding is said to have emerged in the early 1970s. ICI in England developed a high-pressure sequential co-injection process that produced foam-core “sandwich” structures with solid skins. This technique was designed initially to create large parts similar to those made by structural-foam molding, but with the advantage of eliminating undesirable surface swirl and reducing or eliminating post-mold finishing operations. The process initially required two injection presses, but ICI demonstrated the process at the K ’71 show in Dusseldorf on a Windsor machine equipped with a second injection unit.

Battenfeld in Germany believed that ICI’s approach, whereby the skin and core materials enter the mold through a single-channel nozzle, had the disadvantage of causing a clearly noticeable mark on the part surface. This resulted from the switchover from one component to the other, which caused the flow front to hesitate or stop momentarily. In 1972 Battenfeld developed a simultaneous multi-injection approach using a two-channel nozzle that addressed this issue and helped to eliminate part surface defects and obtain better distribution of the core material within the part. The nozzle had two concentric channels, each with its own shutoff at the nozzle tip. The nozzle could inject the materials in sequence or simultaneously. In 1976 Battenfeld demonstrated a new nozzle design that divided the melt streams from two injection units into three channels that could produce thin parts and more consistent parts.