Novel Ejector System Eliminates Plates and Pins

Injection mold cost savings, greater molding productivity, and better part quality are promised for a new ejection system that does away with conventional ejector plates, housings, pins, and risers. This approach is said to reduce mold height, shorten mold-open times by at least 10%, enable better optimization of mold cooling—not to mention eliminating ejector marks on parts.

Called Quick-Strip, this concept is based on a new set of standard components from D-M-E Co. With Quick Strip, “There is no need to focus on the design, machining, and operation of ejector housings. There is no ejector retainer plate, no ejector plate, and no ejector holes to be machined and reamed,” says Robert Starr, director of global marketing services. He adds, “Eliminating ejector-plate actuation improves cycle times. And no more pneumatic, hydraulic, or electric devices are needed to operate the ejector system. Quick Strip is actuated by the mold opening and closing movements.”

Replacing numerous conventional ejector components with the simple two-piece Quick Strip system reduces cost of the mold base and lowers mold height, which sometimes could allow a mold to run in a smaller press. No more ejector pins removes an impediment to optimum placement of cooling channels. And since Quick Strip uses fewer moving parts, mold maintenance is reportedly reduced.

D-M-E says Quick Strip can be used in single-face or stack molds and is best suited to high-speed packaging applications, though it is applicable to a wide range of molding jobs.

HOW IT WORKS

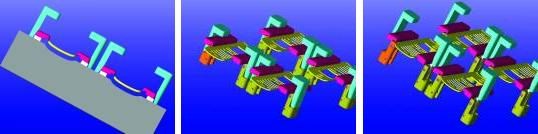

Quick Strip uses two components, one active and one passive. The active component is called the Spoon Assembly. It is typically installed on the stationary half of the mold. The passive component, the Guide Finger, is usually installed on the moving half, although the positions of these components can be reversed.

The Guide Finger acts as a cam guide when the mold opens, controlling the timing and degree of rotation of the Spoons that actually eject the parts. The Guide Finger also resets the Spoon and Spoon arm when the mold closes.

The Spoon or lifter plays several critical roles. It is a rectangular slab of metal measuring 10 x 30 x 90 mm. When the mold is closed, the Spoon is flush with the mold surface on opposite the side, where the Guide Finger is installed. The moldmaker mills out a pocket on the moving mold half where the Spoon is seated when the mold is closed. Also, the surface of the Spoon facing back toward the stationary mold half where it is mounted is milled to match the contour of the part.

The Spoon is positioned so that one edge of its 90-mm length encroaches just 2 mm into the outer edge of the molding cavity. “Part of the Spoon becomes an actual part of the mold contact surface used to form the part,” explains Chuck Azzopardi, global business manager for mold bases and components. The Spoon thus provides ejection force all along its 90-mm length, rather than at a discrete point like an ejector pin. Quick Strip does leave a witness mark on the part, but it is nearly invisible, says Starr. Improved aesthetics was the reason Deva Kunststoff-Technik GmbH of Lemgo, Germany, switched from ejector pins to Quick Strip for molding a new window shade for the Airbus A380 passenger jet.

Since the Spoon interacts with the outer edge of the part, an area that tends to cool first, the molder may be able to eject the part earlier for additional cycle-time savings.

In a typical example, the molded part shrinks around the core side of the mold, which includes the edge of the Spoon. The Spoon is positioned between the part and the core or moving half of the mold. When the mold opens, the Spoon travels with the part on the moving/core half. The Spoon Arm, however, is anchored in the cavity or stationary half. The Spoon is attached to the Spoon Arm, which has a travel slot milled into it that allows the Spoon and its actuator arm to travel along the slot as the mold pulls the Spoon away from the stationary half. When the Spoon reaches the end of the travel slot, it comes to a hard mechanical stop, while the moving mold half continues to retract. At this moment, the Spoon pulls the part off the core half of the mold.

An additional movement of the Quick Strip separates and clears the part from the Spoon. Near the end of the Spoon travel stroke, the Spoon Arm Rotating Spring pushes the Spoon Arm and Spoon in a direction perpendicular to the axis of mold travel and imparts a slight rotation to the Spoon. Cam angles of 8° or 15° on the passive Finger Guide and on the base of the Spoon Arm control the timing and angle of the rotation. This action frees the part from contact with the Spoon. When the mold closes, the Finger Guides return the Spoon to the flush mold position.

Available in three sizes, Quick Strip is made of a steel comparable to P-20, though other steels, such as H-13, are available on request.

Related Content

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreWhat to Do About Weak Weld Lines

Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)