NPE2015: The Right Show at the Right Time

Special Report: NPE2015

In recent years, plastics trade shows in North America have sometimes been written off as out of fashion and in decline. But in around 140 days, a giant plastics trade show in Orlando seems likely to quash emphatically any notions of irrelevance for such industry events.

A just-completed survey of Plastics Technology readers, as well as interviews with various stakeholders—including OEMs, suppliers, and processors—who are headed to NPE2015 as attendees and exhibitors, points to a resurgent show hosting a revived industry.

Mike Ellis, director of global marketing and communications at Milacron LLC in Cincinnati, described 2014 as a “fantastic” year for his company, which has staked out its largest-ever booth—also, by its own estimation, NPE’s largest ever—of 25,000 ft2 for the event at the Orange County Convention Center (OCCC) in Orlando, Fla., March 23-27, 2015.

“I think the timing of the show is perfect, because we’ll still be riding this wave of increased business,” Ellis said. “People are excited, lots of new projects are being kicked off, and we’re seeing lots of reshoring as well. In my opinion, I don’t think the timing of the show could be better.”

Addivant, the Danbury, Conn. additives producer and former business unit of Chemtura, will use NPE2015 to reintroduce itself to the market nearly two years after it stepped out on its own, and will do so with quite auspicious timing, according to CEO Peter Smith. “It is an unbelievably exciting time to be in the industry,” he said, “and I think NPE will be more vibrant and more occupied, if you like, than it has been in many a year. I think it’s going to be a very exciting show for everyone involved.”

Dow Corning, Midland, Mich., skipped exhibiting at the last NPE, but will be on hand next March, according to Gabe Knee, automotive market leader, owing in part to an “uptick” in the North American market. “Dow Corning has not participated in a lot of shows over the last few years,” Knee said, “but we’re really trying to promote these days that our company will be there. We want people, when they’re designing their parts, to think of Dow Corning as a partner. To be out there, we need to have some exposure, and NPE is one way to help gain some of that exposure in the marketplace.”

RUNNING OUT OF ROOM

In an early October interview with Plastics Technology, Brad Williams, dir. sales and marketing at show organizer SPI, Washington, D.C., noted that, with a little over five months until the show opens, NPE2015 was tracking ahead of previous NPEs by several key metrics. In net square feet of exhibit space, Williams said NPE2015 was only about “50,000 ft2 from hitting the walls” at the OCCC, making completely filling the halls a distinct possibility by March 2015.

Williams added that pre-registration was up as well, but he refrained from placing too much stock in that figure, given the late registration habits of most attendees. SPI was most encouraged, however, by hotel bookings, which when he spoke with Plastics Technology were 20% above the same time period in the 2012 NPE cycle.

Williams also noted that there was an uptick in the number of running machines slated to be on display in Orlando. SPI asks exhibitors whether or not they intend to run any equipment on their stand when they sign up for space, and thus far 25% to 30% have said they would operate machinery in Orlando, with 40% planning on bringing equipment, static or otherwise.

Williams believed that the percentage of booths with running machinery would ultimately be about 5% higher than in 2012. That figure is especially interesting when considering that a decline in operating equipment ultimately helped push the triennial event from its long-standing Chicago home prior to the 2012 event. “Exhibitors were worried about the expenses of bringing a machine and running it,” Williams said of Chicago, “but now expenses are right and the market’s in a good place, so there will be a lot of running machines.”

NPE SURVEY: WHAT PT READERS TOLD US

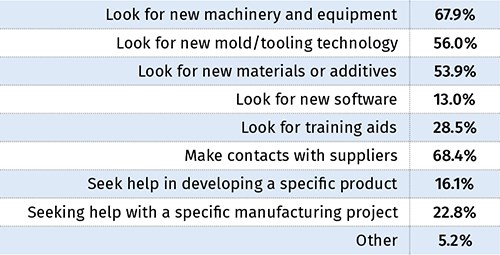

New machinery is certainly on the minds of those planning on attending the show, according to an online reader survey conducted by Plastics Technology in September. Almost 68% of the 229 respondents said looking for new machinery and equipment was their primary reason for attending, with an additional 56% headed to Orlando to find new mold/tooling technology. Nearly 54% said they would visit the show to look for new materials or additives, while 29% will be seeking new software, and 13% will look for training aids. (Scroll down to see the accompanying tables of results.)

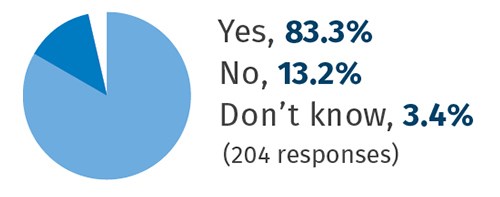

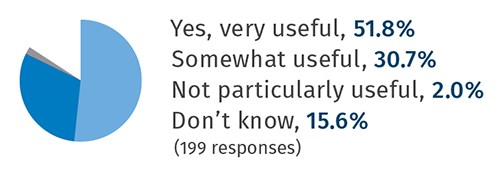

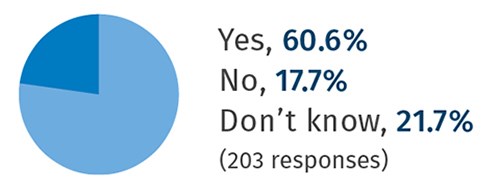

The survey also revealed that for the majority of people that make it to Orlando next March, it will not be their first NPE. Slightly more than 83% of respondents said they had attended an NPE in the past, with a majority (51%) finding the triennial event “very useful,” while an additional 30% described the show as “somewhat useful.” Only 2% said NPE was “not particularly useful.” That value is reflected in the number of people planning on attending, with nearly 61% of respondents saying they or someone from their company would head to Orlando.

MORE THAN 40 YEARS OF NPEs

Count Dale Evans, president of custom injection molder EVCO Plastics, DeForest, Wis., among those planning to make the triennial trek to NPE. Evans first began attending NPE in the early 1970s, following in the footsteps of his father, EVCO founder Don Evans, who walked NPE’s aisles as far back to the event’s inception in the 1950s.

“Keeping current on the latest and greatest technologies in our industry has always been incredibly important to our organization,” Evans told Plastics Technology. Reflecting that desire to keep tabs on industry innovation is the fact that EVCO is planning on sending around 25 of its employees to Orlando in March. They will come from across EVCO’s ranks, including project engineers, toolmakers, automation engineers, and buyers, and will also represent the company’s global operations, hailing from its plants in the U.S., Mexico, and China.

“NPE aggregates the latest and greatest for us, which makes the process of keeping up with the latest technologies and materials more efficient,” Evans said.

That efficiency is also valued by exhibitors, who use it to help secure marketing funds for events like NPE, according to Dow Corning’s Knee. “In normal day-to-day work, we get out and make specific appointments with each customer in their various locations,” Knee explained. “So in a week, we could visit—if we did a good job of scheduling—15 different customers. At NPE we can do that same thing in one day, while accomplishing other goals as well. So there’s a time and cost savings involved with that.”

Those in-person meetings are also part of the draw for trade shows in general, according to Addivant’s Smith. “While the web is a wonderful way of communicating and promoting, it’s not going to replace face-to-face time and experts getting together,” Smith said. “For us, NPE represents a tremendous opportunity to put people together, share best practices, and listen to each other’s needs. That’s why, for Addivant, there won’t be a replacement for shows in the foreseeable future.”

Jarden Corp., Rye, N.Y., a manufacturer of consumer products with more than 120 brands and three primary businesses (Outdoor Solutions, Branded Consumables, and Consumer Solutions) that generated more than $7 billion in sales in 2013, will also be in Orlando, both exhibiting and taking in the show as an attendee seeking new technologies for its plastics processing operations.

Heather McKee, marketing and communications coordinator at the company’s Jarden Process Solutions division, explained that her business will participate in NPE2015 to “showcase the end-to-end capabilities of Jarden Plastic Solutions,” which include design services through distribution, as well as specialty nylon resins and powders from Jarden Applied Materials.

The company, launched in 1993 when Ball Corp. spun off its canning business, first attended NPE in 2003, becoming an exhibitor in 2006. As an attendee, McKee said Jarden representatives will be looking at new technologies to enhance its capabilities, including 3D printing, prototyping, and preproduction.

McKee noted that Jarden won’t necessarily come to the show with money in hand, although it will take an interest in “special deals or show specials.” EVCO, however, will be coming to Orlando ready to invest in hardware. “We’re in a position right now where we have many needs in terms of equipment,” Evans said, adding that his company will be looking at injection machines in the 3000-plus tonnage range, as well as fast mid-sized and small, precise presses. “We will have purchase orders and down payments ready if needed as we approach the show,” Evans added.

RETHINKING MARKETING OF THE SHOW

For Williams, who joined SPI about six months after NPE2012, one of his initial tasks was to talk to the industries that come to the show and see how they view NPE. As part of that effort, SPI hired a marketing firm that’s helping it tailor promotional messaging around the event. “Our goal is not to go out to 50,000 folks with the same message, it’s to go out to 5000 people in 10 different markets,” Williams said, so that SPI delivers 50,000 targeted messages about why people should be at the show and what they’ll see when they’re there. “We’re just trying to be a little more intelligent about targeted marketing.”

Rethinking the messaging has also meant rethinking the event, Williams said, including acknowledging the various end markets that attend to see specific advances in an application sector versus broader developments for plastics as a whole.

“We think NPE is a packaging show, an automotive show, an appliance show, a consumer-products/electronics show,” Williams explained. “All those end markets make up our attendee base. We really need our marketing terminology and copy to reflect how we can serve those industries.”

TARGETING OEMs & DESIGNERS

SPI is also aiming to get more designers and brand owners/OEMs to attend, acknowledging their role in the greater plastics supply chain. “NPE had a pretty good core market,” Williams noted. “Machinery folks, material suppliers, and processors. But from the front end, what about the design and research aspect of it? It’s not that designers haven’t come, it’s not the brand owners haven’t come, but I think if we build a better reason for them to come and make them feel like this is their show and they have a place and they’re a part of it, it just makes it that much better.”

For exhibitors like Addivant, the effort to encourage participation along the entire plastics supply chain is welcome. “At the end of the day, we look at business as a value chain,” Addivant’s Smith said, “and obviously the ultimate solution typically ends up in the hands of the consumer, so we like to understand the needs throughout that value chain, and the best way to do that is to meet with all stakeholders.”

Getting the entire value chain to Orlando will take one thing, according to Dow Corning’s Knee: innovation. “Shows where I’ve seen a lot of brand owners, where I’ve seen the greatest participation, are ones where I’ve seen a lot of innovation being presented,” Knee said. “Innovation tends to attract not only the brand owners but their suppliers and the whole industry as well. Where you see a lot of quality presentations and quality innovations being presented, people recognize it.”

NEW AND IMPROVED NPE

SPI has also created some new spaces, and expanded existing ones, to better accommodate the entire supply chain. In 2012, it promoted meeting rooms for material suppliers, replacing traditional booth space on the show floor with standalone rooms away from the exhibits, where resin makers could conduct more private meetings with customers. In 2015, that effort will be expanded, growing from six meetings rooms to 14 or 15 and including companies like Dow Chemical, Formosa, ExxonMobil Chemical, DSM, and Sasol, among others.

Another element tested in 2012 and to be expanded in 2015, is what SPI calls “Mission Control Centers” for brand owners and OEMs. Basically the program entails a private space at the show where teams from OEMs can meet and plan their NPE. Ford Motor Co. was an early adopter and has signed up once again, with packaging giant Berry Plastics having locked down a space just days before Williams spoke with Plastics Technology

SPI has also partnered with the IDSA (Industrial Designers Society of America, idsa.org), to create the IDSA Design Center. Williams noted that SPI had opened up space in the center “for only a couple weeks” as of early October, and the reaction was strong enough that SPI has already chosen to expand the area to 4000 ft2 to accommodate around 15 exhibitors (up from an anticipated eight or nine). In addition, IDSA has also rescheduled its southern district design conference to be held in conjunction with NPE.

WHAT PT READERS TOLD US ABOUT NPE15

Table 1: Have you or others in your company attended NPE in the past?

Table 2: Have you found attending NPE to be useful?

Table 3: Do you think you or other members of your company will attend NPE 2015?

Table 4: For those attending, what are the main purposes?

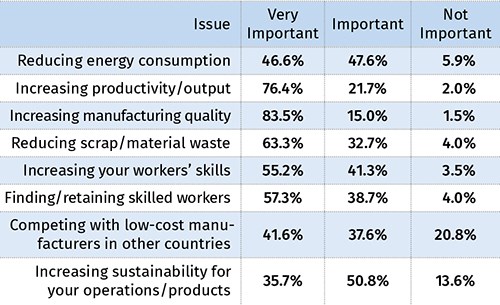

Table 5: How important are these industry issues to your company?

Related Content

As Currier Grows in Medical Consumables, Blow Molding Is Its ‘Foot in the Door’

Currier Plastics has added substantial capacity recently in both injection and blow molding for medical/pharmaceutical products, including several machines to occupy a new, large clean room.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)