Polyurethanes: Fine-Tuning Insulation Foams

Thermal insulation has become ‘eco-friendly,’ but now the challenge is to optimize economics, processing, and performance.

Nearly two years after the mandatory conversion to “cleaner” blowing agents in the major segments of polyurethane foam production, the transition continues to evolve. After solving the immediate problems of conversion, market competition is driving many foam processors to reformulate anew for lower costs and/or improved processing.

This ongoing evolution was a major theme in technical papers presented at the recent Polyurethanes 2006 conference in Salt Lake City, sponsored by the Alliance of the Polyurethanes Industry (API). Among the newer developments discussed were next-generation polyols for rigid foams in building and construction and a blowing-agent-enhancing additive for insulation blown with HFC-245fa in appliances and construction.

Another conversion is pending for several smaller sectors of PUR rigid foams, such as pressure/froth and pour-in-place types, which previously switched under EPA mandate from HCFC-141b to HCFC-22. The latter was only a temporary substitute because it too was slated for phase-out on Jan. 1, 2010 under Section 612 of the Clean Air Act, but it might end up being phased out sooner.

Also notable at the conference were new PUR technologies for auto interiors. This includes a novel spray process for acoustic insulation and a soft-touch aromatic PUR skin technology for aesthetic coverstock.

Replacing HCFC-22

A new twist in the pending phase-out of HCFC-22 could move the date up by two years to Jan. 1, 2008. Next month, the EPA is expected to publish such a recommendation based on a study that concluded that non-ODP blowing agents are readily available to allow for an earlier conversion in the remaining rigid foam sectors where HCFC-22 gained widespread use in the last three years. These include commercial refrigeration (e.g., walk-in freezers, large reach-in coolers, and transport reefers), entry and garage doors, and architectural building panels–including both continuous and discontinuous metal-faced foam panels.

Processors facing such a conversion will have to balance the cost of alternative blowing agents against effects on processing and foam properties. HCFC-22 costs around $1.50/lb. Among the alternatives are two gaseous, non-flammable hydrofluorocarbons that already dominate pour-in-place foam insulation for domestic refrigerators and water heaters and rigid spray-foam insulation for walls, roofs, tanks, and spas. One is HFC-245fa (sold as Enovate 3000 by the sole North American producer, Honeywell International), whose price rose in the past year from $4/lb to about $4.50/lb. Another alternative, HFC-134a, rose from $2/lb to nearly $3/lb.

Also in the running are hydrocarbons–isopentane, n-pentane, and cyclopentane–costing 50¢ to 90¢/lb, as well as liquid, methyl-formate based Ecomate from Foam Supplies, which is used in spray-foam insulation and integral-skin foams for bicycle seats, golf-cart tires, and automotive headrests. Ecomate is completely miscible with other blowing agents and is said to provide insulation value between that of HFC-245fa and pentanes. Moreover, its price is comparable to hydrocarbons, and like them it is flammable. Other candidates are water blowing and combinations of blowing agents.

At the conference, at least three presentations addressed HCFC-22 replacement. Researchers at Bayer MaterialScience evaluated alternative blowing agents in two commercial HCFC-22 blown foam systems for refrigerated trailers and entry doors. For trailers, Bayer found that HFC-134a, HFC-245fa, and an 80/20 cyclo/iso pentane blend each can produce foam properties comparable to HCFC-22. Long-term dimensional stability and foam adhesion to facers were not thoroughly evaluated. But Bayer did find that uncut panels made with the pentane blend showed signs of shrinkage after one month at ambient conditions, whereas panels made with the HFCs and HCFC-22 had no shrinkage.

Entry doors were made with foams blown with HFC-134a, HFC-245fa, cyclopentane, and water. All four blowing agents yielded properties generally similar to HCFC-22 blown foam. The water-blown system gave a higher minimum fill density and overall panel density, while the HFC-245fa foam had slightly lower compressive and tensile properties. Long-term effects and adhesion properties were not compared.

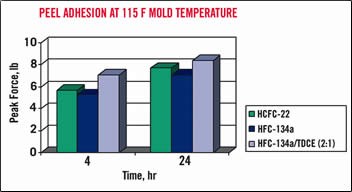

Meanwhile, Arkema reported on tests of a blend of HFC-134a with the company’s Transcend TDCE (trans-1,2-dichloroethylene) in place of HCFC-22 in a generic pour-in-place formulation. Arkema has previously demonstrated TDCE’s effectiveness in reducing the vapor pressure and viscosity of 134a/polyol premixes and in dramatically reducing the degree of frothing and number of pinholes (see “Learn More” box).

The researchers replaced part of the HFC-134a and part of the water with TDCE so that the molar blowing ratios of HFC-134a/TDCE/CO2 were 50:25:25. This formulation gave easier handling due to lower vapor pressure and faster blowing-agent addition to the polyol blend. Moreover, it provided improved flow, superior adhesion, and excellent dimensional stability over the 134a control and was at least comparable to the HCFC-22 control. Thermal conductivity with TDCE was also satisfactory.

Foam Supplies reports that its Ecomate blowing agent can produce more economical pour-in-place foams with good dimensional stability and excellent flame resistance at low densities. The company sees Ecomate having the greatest potential for replacing HCFC-22 in entry and garage doors. The company’s Eco1 pour foam system was recently granted a 25FS/300 smoke rating at thickness up to 6 in. by Underwriters Laboratories, and a customer reports that this formulation passed Factory Mutual’s full-scale Corner Wall burn test.

New polyols for rigids

Improved polyester polyols for both HFC-245fa pour-in-place appliance insulation and pentane-blown panels and spray foams were discussed by Oxid L.P. The company originally set out to develop polyols with even higher functionality than workhorse Terol 256 in order to counteract the softening effect of HCFC-141b. While HFC-245fa does not weaken foam nearly as much, it does result in diminished fire properties, requiring more polyester polyol in the formulation. New Terol 925 with a nominal functionality of 2.45 was compared in a panel formulation with existing Terol 250, 305, and 256, which have functionalities of 2, 2.15, and 2.30, respectively. The green strength (GS) test was started at 18 min and data was collected up to 30 min. (The GS apparatus measures the penetration by a weight into the bun.) At 20 min, the foam made with Terol 925 had a GS of 6.5 mm compared with 9.9 to 15.8 mm for the other polyols. At 30 min, its GS was 9.2 mm vs. 14 to 20.8 mm for the others. According to Oxid researchers, higher-functionality polyesters make harder foams much more quickly, which translates for the panel maker into faster demold times or use of less polyester to maintain the same demold times.

Oxid also discussed two new candidates whose early trial performance looks very promising for pentane-blown continuous and discontinuous panels and spray foams. These have been produced using Oxid technology that overcomes the inherently low solubility of pentanes in polyester polyols and also allows for higher functionality. Much greater solubility is claimed with DS 1220 (44 pphp) and DS 1240 (40 pphp) than with existing products such as Terol 305 and 256 (4 to 6 pphp).

In addition, Oxid reported on new low-hydroxyl-number polyester polyols that allow for reduced isocyanate consumption without jeopardizing physical properties or fire performance of pentane-blown polyisocyanurate (PIR) insulation boards. This development was spurred by the shortage of polymeric MDI last year. Polyol producers were asked to develop polyesters in the 200 OH (overall hydroxyl) range, which would cut isocyanate needs by 7% to 10%.

Oxid came up with functionalized polyols whose OH has been reduced with reactive additives instead of the typical non-reactive additives that can degrade foam dimensional and thermal stability. Laminator trials reportedly show that one candidate, DS 1154 (200 OH), surpasses workhorse polyester Terol 563 (245 OH) in physical and fire properties as well as flow. Researchers are now looking at various catalysts and surfactants that can further optimize DS 1154 foams, and early studies have demonstrated that fine cell structure and good initial K-factor can be achieved without a surfactant.

Enhancer for spray foams

When first used in commercial PUR foams, HFC-245fa was found to increase viscosity, which limited the versatility of such systems. Air Products and Chemicals has developed additives that overcome this effect and have other benefits as well. Dabco PM-200 was introduced at the API conference in 2003. This year, Air Products presented Dabco PM-300, an additive that enhances HFC-245fa blown appliance insulation and appears to have potential in rigid spray foams.

In appliances, this additive reportedly reduces viscosity of the polyol blend and permits cost savings by reducing the concentration of HFC-245fa, or reducing density at the same concentration, while maintaining thermal and mechanical properties. In recent trials with HFC-245fa spray foams, Dabco PM-300 again achieved lower density or allowed use of 20% to 30% less HFC-245fa without increasing density. Spray foams with PM-300 also reportedly had improved compressive strength, which is important for dimensional stability when reducing density. The additive also is said to have little impact on K-factor. By reducing mix viscosity, PM-300 allows spray foam manufacturers to use a variety of polyol types and provides improved mixing and foam quality. Moreover, PM-300 also creates a finer cell structure and improved substrate and interlaminate adhesion, which is important for cold-weather spraying.

Spray acoustic insulation

A novel technology for making acoustic insulating components used in automotive interiors was unveiled by Cannon. SoliSpray is a spray process that deposits thick layers of PUR filled with heavy materials such as barite and iron oxide. Cannon says this technology is a practical alternative to the usual methods of RRIM or thermoforming filled thermoplastic sheets.

SoliSpray’s major advantage is that it allows production of acoustic insulating components–typically low-margin items–without having to use costly presses and molds. The technique lets you spray heavily filled PUR directly into an open mold, which then moves into a press to be back-foamed in a closed mold by injecting flexible low-density polyurethane. It offers the flexibility to vary the local thickness of the sprayed layer, optimizing use of raw materials and offering potential cost savings.

SoliSpray combines recent Cannon developments–especially the FPL 10 mixing head for filled materials, which is also light and easy to handle. The unit was modified with a spray nozzle de signed to apply precise, uniform lines of a highly homogeneous reactive mix with good control over thickness and extremely low overspray. The head was also automated to allow for consistent application of the foam across a large area. A six-axis jointed-arm robot is used because it can reach all points of the mold and can orient its wrist to reach any vertical walls.

The metering machine can be any of a range of available options, as long as it is a high-pressure type with at least one feed line capable of working with a highly viscous polyol loaded with abrasive mineral fillers.

For simple pieces of acoustic insulation made with a single layer of filled polyurethane, the material can be sprayed directly into the mold. Such parts have one smooth and one rough surface, which is acceptable as they go directly up against the bodywork and are out of sight. A press is not needed, only a simple support to retain the half-mold.

For carpet underlay, the acoustic insulation can be sprayed directly onto the back of the carpet once it has been placed in a mold.

To make a sandwich of one layer of acoustic insulation and one of sound-absorbing foam (the most frequent combination), the acoustic insulation can be sprayed directly into the lower mold half. A traditional polyurethane foam is then bonded to it with the mold either open or closed. A press and a standard mold are all that is needed.

To complement SoliSpray, Cannon also developed Foam & Film technology, which allows for thin thermoplastic films to be thermoformed directly on the surface of the mold and then backed up with foam.

Soft-touch aromatic PUR

A soft-touch foamed skin technology for automotive interior coverstocks was discussed by Dow Chemical. Most of the R&D work was conducted at Dow’s Polyurethane Systems business in Correggio, Italy. Dow developed a new family of aromatic-based, soft-touch RIM PUR polymers that can be injected or sprayed in the mold. The technology allows single-shot production of parts with different degrees of softness. With RIM processing, final density ranges from 1.05 to 0.7 g/cc for a wall thickness of 0.8 mm or as light as 0.4 g/cc with thickness up to 15 mm.

Aromatic PUR systems are a much more economical and better performing solution than the aliphatic PUR alternative, Dow says. Compared with thermoformed TPO, TPU, or PVC films, Dow’s materials reportedly provide better grain retention (with both spray and RIM), softer feel, and lower cost. Dow also cites reduced emissions and fogging. A 100% PUR system such as an instrument panel can be achieved by combining the PUR soft skin with a rigid PUR substrate such as Dow’s new-generation Spectrim RL 700 series low-density RIM (LD-RRIM) resin.

Read Next

Polyurethanes: Foams Go 'Green' at Ever-Lower Cost

A great deal of effort is going into formulating rigid and flexible foams for lower cost and better properties, despite the transition to "cleaner" blowing agents. Improving fire and smoke performance is another challenge.

Read MorePolyurethanes: Fine-Tuning 'Green' Foams

With the switch to ‘cleaner’ blowing agents nearly complete, the priority now is tweaking foam formulations for optimal performance and cost.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More

.png;maxWidth=300;quality=90)