Recycled Plastics Prices Unstable In First Half of 2012

WEB EXCLUSIVE: Recycled plastic prices are plummeting as virgin materials’ prices slide lower and lower.

WEB EXCLUSIVE: Recycled plastic prices are plummeting as virgin materials’ prices slide lower and lower. It has been a bit of a rollercoaster ride for the first half of the year. Prices were up January through April in most materials, but have since slid back down. With little strength in the economy, customers are buying only what they need and not holding any inventory as they wait for the lower prices that are likely to come.

While lower prices are good for processors, that hasn’t been enough to spur demand. “That situation is not expected to change until prices fall to the point that will allow new demand, and I don’t know where that point is,” said one industry analyst.

R-HDPE PRICES SLUMP WITH AMPLE SUPPLY

According to one recycler, “Recycled HDPE prices peaked in April. We saw mixed-color flake selling in the 53¢ to 54¢/lb range. We came into a lot of high demand early in the year with such a mild winter. Pipe manufacturers kept making and selling product. That seemed to clean out available post-industrial and post-consumer feedstock. Prices were inflated by demand.” In the last two months, however, more recycling capacity has added to supply and prices have started to come down. That’s expected to continue through the summer.

R-PET MARKETS & PRICES COLLAPSE

The West Coast and East Coast R-PET businesses continue to be quite separate. On the West Coast, “Business this year has been good with bale prices low,” said one reprocessor. “I have been saving about $1.2 million a month. On the other side of the coin, my selling prices have gone down as well. The market is collapsing in China so they are dumping their resins in California. In June, prices were 23.5¢/lb for bales in California.”

Clear flake prices on the West Coast, are in the low 60¢/lb range, sources there expect them to slide down into the 50s. Meanwhile, East Coast prices began to erode in April but are still holding around 68¢ to 82¢, one source said.

All this leaves recyclers shaking their heads. Said one, “I don’t recall a situation where you went into spring and summer and demand absolutely disappeared before you hit the first day of summer. We have seen lower pricing in the past, but there has always been a specific reason, for example. a storm or a plant shutdown. But, this time, it is the overall market. You can see a change of as much as 30¢ in 45 days…That’s huge.”

Related Content

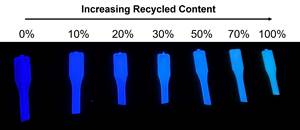

Fast, Simple QC Method Directly Quantifies Recycled Content in Plastics

Novel fluorescence-based spin-out technology provides a rapid and reliable method to measure and certify recycled content in a wide range of plastics.

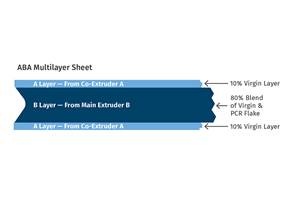

Read MoreThermoforming PCR: An Equipment Supplier’s Pointers

Thermoforming PCR is not radically different from forming virgin, but variation in recycled materials can require extra care to get a consistent end result. Start by examining every aspect of the process from the sheet (and extrusion process if run inline) to the final trim.

Read MoreEvolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More

.png;maxWidth=300;quality=90)