RECYCLING and SCRAP RECLAIM: New Family of Shredders

Called the Raptor Series, these modularly designed units from Rapid Granulator feature a reported “world-first open-hearted” design.

Size-reduction technology specialist Rapid Granulator, Bredaryd, Sweden, is introducing a new family of shredders for plastics. Called the Raptor Series, these modularly designed units feature a reported “world-first open-hearted” design. Other notable design features include a unique cutting system, tilt-back hopper, and design for integrated granulation. Rapid will display this new Raptor Series during K 2016 (Hall 9; stand E19).

“The Raptor Series is a shredder and granulator hybrid with the shredder’s heavy-duty cutting technology combined with granulator features such as Rapid’s 'open hearted' design that makes it super-easy to operate, service and clean,” says Rapid CEO Bengt Rimark. “The Raptor Series has been developed with 100% focus on every single detail that is of importance for plastic processors, in order to create simplicity and a minimum cost of ownership. As we develop and manufacture both granulators and shredders, we make sure that the machines are tailored for each other and that we can provide complete recycling systems, direct from Rapid.”

The Rapid “open hearted” design of the unit enables quick and direct access to the shredder rotor and cutter chamber, simplifying the cleaning and service process. The front door, hinged on the side, provides unrestricted access to the rotor and to the screen, which is mounted in the door. Once the front door is open, the shredder hopper mounted on a rear hinge can be tilted back.

Rapid offers 36 base configurations of the Raptor in order to handle various customer applications. The modular systems feature two diameters and two widths (31.5” and 53”/ 800 mm and 1.350 mm). There are two system designs for pushing material into the rotor—FlexiPUSH and PowerPUSH. The PowerPUSH is available with an extended pusher length (PowerPUSH-XT); there are also three different cutting systems: Quad Cut, Claw and Power Wedge.

The low cost of ownership of the new Raptor Series is accomplished through the ease and speed with which it can be cleaned and maintained. The machine can be in a completely open position in less than one minute after it has stopped running. Once the machine is open, all fasteners are accessible from the outside using air driven tools. The access made possible by the “open hearted” designs makes any contamination immediately visible.

The tilting hopper opens with an electrically operated jack, while the screen and granule bin can be handled by a single operator. The unique screen cradle design does not require the removal of bolts in order to remove the screen, and the granule bin slides out easily. The same tool is used to unlock the front door and to rotate the rotor. As an option, a light can be fitted to provide extra illumination.

The FlexiPUSH is a pneumatically driven pusher and is intended for handling basic applications, including lumpy materials. It can handle large products such as a 1200-L IBC (Intermediate Bulk Container) for example. The hydraulically powered PowerPUSH maximizes output for shredding sheet and film. The cutting chamber features a textured floor to reduce the risk of material adhering or finding its way under the pusher and is offset by 5 degrees to enable liquids to drain away.

The unique QuadCUT cutting system for general plastic waste features a solid knife that allows the full use of all four cutting edges. The cutting system is extremely durable and has a rock solid clamping system attaching the knife to the rotor. The knives are supported by a sacrificial washer in order to protect the rotor should non-plastic material accidently enter the cutting chamber.

The base of the Raptor Shedder series is also equipped with the Rapid MCB feature (Mineral Composite Base) which absorbs stress and vibration during operation and gives the shredder a very solid footing and a low center of gravity.

The Raptors can also be configured in the Rapid DUO concept, with a floor-standing granulator located directly beneath the output of the shredder.

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreA Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

Read MoreFilm Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

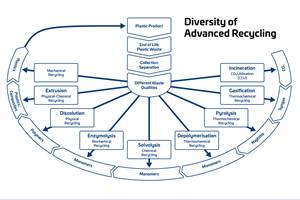

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More