Rotary Thermoforming Gets Bigger and Better

Thermoformed Products Inc. (TPI) in Muskegon, Mich., has always been a large-parts specialist.

Thermoformed Products Inc. (TPI) in Muskegon, Mich., has always been a large-parts specialist. It pioneered twin-sheet forming of parts up to 8 or 9 ft long. Last year, this family-run custom firm installed one of the largest rotary thermoforming machines ever built. With this four-station behemoth, whose forming area is 10 x 20 ft and maximum draw depth is 48 in., TPI is producing larger parts than ever before and is making them more efficiently by running multiple tools at once.

Dave Harris, v.p. of manufacturing, says TPI can form three 16-ft-long slides for outdoor playsets at one time on this machine. It's also not uncommon for TPI to form three 6 x 9 ft products together. According to Harris, TPI is also the first thermoformer to challenge thermoset fiberglass composites in making canoes up to 15 ft long. Harris calls this a breakthrough in size for thermoformed water craft, which previously available machinery limited to a maximum of 13 ft.

What makes such ambitious forming jobs possible is the mammoth R-224-E four-station rotary from Brown Machine LLC, Beaverton, Mich. The machine had to be built and shipped to TPI in sections. It has a proprietary clamping system to handle sheets up to 124 x 244 in. But this is no lumbering giant. It is fast and accurate, indexing 90° in 7 sec. Variable-frequency electric motors add a delicate touch to platen movements, capable of increments as small as 1 mm.

Multiple personalities

A huge forming area gives TPI the means to run large parts profitably in low volumes of 100 to 5000 parts. The secret is simultaneous forming of multiple parts from sheets of different colors and thicknesses (0.190 to 0.300 in.) and with draw depths varying from 4 to 48 in. A special stacking and loading station on the machine can handle multiple sheets per cycle.

TPI mounts up to six separate molds, or single tools with up to eight cavities, to make products for automotive, recreational, and agricultural uses. The cavities can be different as well. TPI recently produced an automotive pallet that holds six different parts. "The customer thought he would need six different trays, but it took only one," says Harris.

Molding multiple parts or cavities requires not only 520 individually programmable ceramic oven zones (260 top and bottom), but also three zones of vacuum control top and bottom, and profiled vacuum within each zone. An advanced process controller monitors temperature of the mold and the ambient air to help control this tricky process.

Makes own sheet & molds

Harris says precise heating of one giant sheet or several individual pieces is critical to good part forming. "Heating the sheet can be a problem. Everything has to come out of the oven at the same time and at the perfect forming temperature." TPI extrudes its own sheet to get more control of the process. "Producing our own sheet allows us to orient the molecules in the sheet for more or less sag, so that deep- or shallow-draw parts can be made from sheet with similar starting gauges," Harris explains.

TPI makes all its own molds, primarily of cast aluminum. The rest are of wood, ceramic, or epoxy. The mold department developed an innovative way to join modular tools together to make a single multi-cavity mold. This allows customers to start production of a new part with one or two cavities and later to expand production by adding more identical mold modules.

Related Content

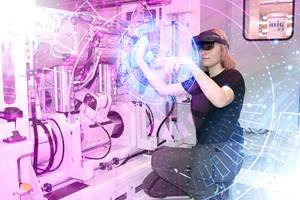

Enhanced Digitization in Thermoforming

Illig’s Easy product family includes the newly developed Human Machine Interface, Illig Easy Touch.

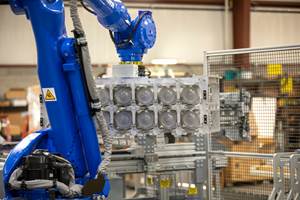

Read MoreAn Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreThermoformer Maximizes Productivity with 3D Printing

Productive Plastics has created an extensive collection of 3D printed manufacturing aids that sharply reduce lead times.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)