Smart Tool, Electric Tool

The old gray mold ain’t what she used to be. Or won’t be for long, if recent trends hold up.

The old gray mold ain’t what she used to be. Or won’t be for long, if recent trends hold up.

Those trends will be evident to some extent at next month’s K 2016 show in Dusseldorf, so if you’re going, you can judge for yourself.

Trend 1: Mold with a Brain

As detailed in our K Show preview last month, one of the more prominent trends at the show will be the industry-wide evolution (more consciously in Europe than here) toward the “smart factory” of self-directed, interconnected machines, known under the rubric “Industry 4.0.”

The problem is that, while injection machines and auxiliaries have been getting smarter and smarter, one fundamental part of the process remains “dumb”—the mold. That’s dumb in two senses—it doesn’t think and it doesn’t talk or communicate.

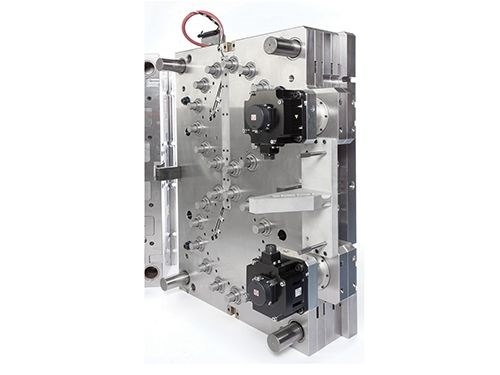

Milacron in Cincinnati has been working on a multi-year project to do something about this. The result, exhibited at K, is Smart Mold, a metal box (photo below) that attaches to a tool equipped with cavity sensors. The box contains software to extract and communicate data from those sensors via web server and OPC-UA server, as well as logic and storage capacity to save setup recipes for the entire cell that works around that mold, as well as preventive maintenance routines, engineering change records, etc.

Think of that—a mold that can tell the injection press, auxiliary injector (for two-shot molding), hot-runner system, robot, chiller, etc. what settings to implement so the mold can do its job. (For more on Smart Mold, see the results of an exclusive interview in October’s Starting Up.)

Trend 2: Going Electric

The October story notes that Milacron will be introducing another new product, as yet unnamed, that controls six servo axes on the mold—valve gates, top and bottom stripper plates, and two rotary axes such as a spin stack or rotary table and an index plate. Milacron is only one of a handful of companies that seek to replace hydraulic tooling functions with electric servos and/or stepper motors, which are clean, compact, fast, and more affordable than ever.

In an October Close Up, I report on my visit this summer to NyproMold in Clinton, Mass., which has pioneered high-cavitation unscrewing molds with electric “continuous cam” action in place of the cumbersome rack-and-pinion mechanisms of the past (photo below).

There’s also the Altanium servo control from Husky Injection Molding Systems, Bolton, Ont., a fairly new module (shown at NPE2015) for its hot-runner controller that controls servo axes in the mold—valve gates, collapsible cores, slides, unscrewing, stack rotation, and coining motions. Husky will exhibit at K, too.

And as far back as K 2010, Hasco of Germany (U.S. office in Fletcher, N.C.) showed off an all-electric mold with servos controlling every action in the tool. Hasco also will show off its latest at K.

Related Content

-

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

-

IPEX Opens Injection Molding Facility in North Carolina

The pipe and fittings manufacturer’s new 200,000-square-foot facility represents a $200 million investment and will create 150 jobs.

-

Compact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.