SPI Launches Sustainability Benchmarking Tool

With the launch of its Sustainability Benchmarking Tool this month, SPI will host a webinar. "Zero Waste Zone" at NPE 2015 further supports effort.

This month, SPI is launching the plastics industry Sustainability Benchmarking Tool and will be hosting a webinar for members on Thursday, January 15 at 1 pm ET. The announcement was made in late December by Fred Daniell, SPI’s chairman of the board of directors, and president of Kureha America.

Daniell noted that as the U.S.’ third largest manufacturing sector, the plastics industry has a great economic story to tell, but has an important environmental story to tell as well. “The industry is achieving environmental success through the sustainability benefits of our products and the strides the industry is taking to ensure the manufacturing of those products are done in a way that is efficient and minimizes the environmental impacts where possible.”

The information gathered through the new Sustainability Benchmarking Tool is expected to provide SPI with the data needed to both “tell that positive environmental story and shape the conversations about our industry,” according to Daniell. Noting that SPI’s advocacy is based on sound science—which is based on data, he implores members to help build the database needed in order to turn the industry’s anecdotal debate into data-driven policy. He adds that in addition to supporting this industry effort, member companies will also be afforded numerous benefits, including:

• Benchmarking your company’s sustainability practices.

• Undertaking an inventory of sustainability activities if your company has not yet done this.

• Generating varying levels of reports through the tools to share with customers, or being the critical first step in generating your own corporate sustainability report.

• Identifying areas of success and opportunities for improvement.

• Having the information to tell about your own sustainability activities to your employees, community and customers.

The information collected, as with all SPI surveys, will remain confidential by a third party. Only aggregated industry information will be publicly shared.

Meanwhile, SPI will dedicate a special sector of the exhibit floor at NPE2015. Reflecting SPI’s commitment to pursuing zero waste, the Zero Waste Zone will present recycling demonstrations, multiple displays of products made with post-consumer recycled material, a cradle-to-cradle education experience, and special events.

Surrounding the Zero Waste Zone will be the Recycling Pavilion, with exhibits by recycling companies and suppliers of recycling technologies, and the Sustainability Pavilion, featuring technologies that benefit the environment. The entire sector will be located in the South Hall of the Orange County Convention Center, the venue for NPE2015 in Orlando, Florida. Among the programs already planned are:

• Recycling demonstration by Rapid Granulator Inc., which will process PET products into reusable flakes.

• Products made from recycled plastics, displayed by companies such as Dell, EcoStrate, Green Toys, Preserve Products, Seventh Generation, and TerraCycle.

• PET recycling / sustainability van provided by the HB Media publication PETplanet Insider.

• ‘Pursuing Zero Waste’ Wall’, where NPE2015 attendees can pin their business cards to show their commitment to zero waste (and become eligible to win a motorcycle).

• International Beer Garden, an attendee networking spot opening at 11 A.M. daily, where special events will be held.

“The reuse and recycling of plastics, as well as the reduction of plastics waste, are top priorities in our industry and for SPI and its industry partners,” said Gene Sanders, SPI’s senior vice president of trade shows and conferences. “The Zero Waste Zone and the surrounding Recycling and Sustainability Pavilions will provide attendees with concentrated access to companies and technologies that have made it their business to address these themes and develop workable solutions.”

Related Content

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

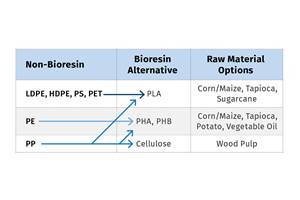

Read MoreHow to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

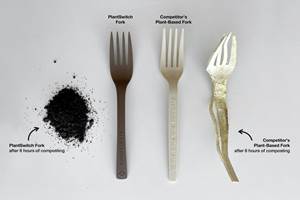

Read MoreAdvanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

Read MoreCJ Bio’s Amorphous PHA Demonstrates Excellent Biodegradability in Marine environment

The tests of the bioplastic, a semi-crystalline PHA and a PLA were conducted by the national Korean testing agency (KCL)

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More

.png;maxWidth=300;quality=90)