‘Sqrounds’, ‘billboard’, and why in-mold labeling is taking off

An increasingly popular packaging format, which lends itself to IML, could help the decoration technology finally take off in North America.

Long held up as a technology to watch, in-mold labeling (IML) had failed to win the same popularity in North America that it enjoyed in Europe, but is that now changing thanks to a growing packaging format and shelf-appeal-focused point-of-purchase product marketing?

Business is booming at custom automation supplier CBW, Fort Collins, Colo., and that success is due in no small part to increased interest in IML systems, particularly for square/round “sqround” containers that are increasingly showing up on retailer shelves.

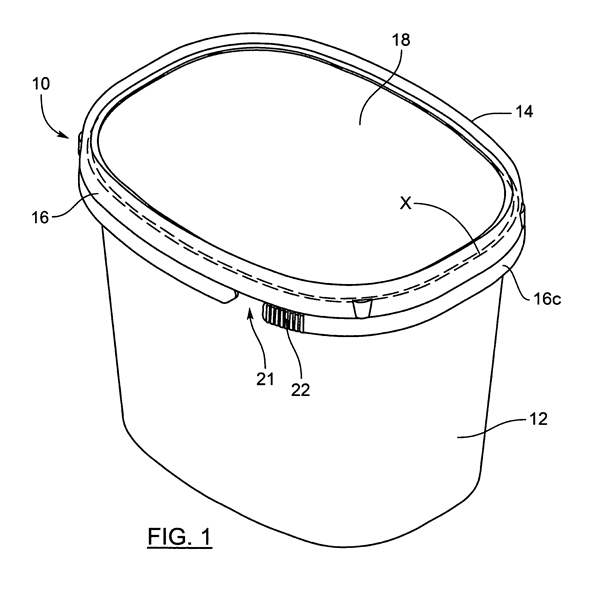

Sqround, or rather sqround™ (the term was trademarked by Berry Plastics in 1995), refers to containers that are largely rectangular in shape, save for their corners, which are rounded. This style of package replaced strictly round containers, which were most easily decorated via pad printing, or in the case of ice cream, coated paperboard bricks (much to some folks’ lament).

Jim Swim, business manager at CBW, has multiple sqround packages at the ready as props in his Fort Collins office to help explain the phenomenon. “In the old days, the market would have a cup—a round cup—so we would mold these,” Swim says, “then we’d take them out and they’d got to a printer. But when you start getting something like this,” Swim says, pulling a rectangular sqround from his shelf bearing a very familiar brand name, “you can’t print them real fast, it doesn’t spin.”

Swim says CBW delivered its first IML system in 2005, and since then, the market has taken off with 70 and counting operating in a variety of markets. “[Sqround containers] are required from the Big Box stores,” Swim says. “They can get more of these on a shelf and then they can have more visualization for the customer. This is where these markets have emerged based upon the requirements of the Wal-Mart’s or the Target’s of the world, because they want to maximize the product on the shelf and maximize the exposure of the product, which is where IML really helps.”

Related Content

-

Plastics Technology’s Most-Viewed Articles from 2022

Tips, new technologies, resin pricing, best practices and more piqued reader interest at Plastics Technology in 2022.

-

Can Plastic Recyclates be Welded Ultrasonically?

What is possible with ultrasound? Will the result with recycled plastics material actually be worse than with standard material? Do we have to adapt our technology?

-

Hot Wash Systems for Recycling Polyolefins

Herbold can configure wash plants for polyolefins that can produce high-quality, food-grade recyclates.

.png;maxWidth=300;quality=90)