Sub-Micron Additives Make Strides (Just Don’t Say ‘Nano’)

High-surface-area, sub-micron-size additives have been making significant commercial strides in thermoplastic applications, albeit generally later than had been expected just a decade ago.

High-surface-area, sub-micron-size additives have been making significant commercial strides in thermoplastic applications, albeit generally later than had been expected just a decade ago. Moreover, they are playing functional roles such as biocides, barrier additives, flame retardants, and electrostatic dissipation (ESD) agents, in addition to fulfilling their initially expected role as reinforcing fillers.

At their debut, these additives were mostly referred to as “nanoparticles.” A nanometer is 1 billionth of a meter and 100,000 times thinner than a human hair. When applied to plastics and other materials, the definition of “nano” is often determined by the supplier. A definition used by PPG Industries, one pioneer in commercial nano applications (for architectural coatings), is that nanoparticles are materials with at least one dimension less than 100 nm (0.0001 mm or 0.00004 in).

More recently, notes Chris DeArmitt, chief technology officer at Applied Minerals, the U.S. EPA proposed a definition of a “nanoscale material” as “an active or inert ingredient and any component parts thereof intentionally produced to have at least one dimension that measures between approximately 1 and 100 nanometers (nm).”

Nanoparticles have come to the attention of the U.S. EPA and the EU’s REACH (Registration, Evaluation, Authorization & Restriction) regulators on chemicals and their safety. Although no danger has been demonstrated, U.S. and EU regulatory bodies have concluded that nanoparticles—especially those smaller than 30 nm—have the potential to pose an entirely new health risk and that it is necessary to carry out an extensive analysis of such risk. As a result, suppliers of these additives have become cautious about the terminology used, sometimes arguing that some dimensions of their additives are in the micron range (1000 nm).

At least one company, Spain’s Nanobiomatters Industries (nanobiomatters.com) is now referring to itself as NBM, and others are said to be considering similar name changes to avoid any potential “nano” stigma. So far, neither engineered nanoparticles nor the products and materials that contain them are subject to any special regulation regarding production, handling, or labeling. It is also maintained by some suppliers that not all nanoparticles are of concern because some naturally based materials have a long history of safe use (see sidebar).

In the meantime, commercial successes of sub-micron additives are multiplying. In thermoplastics, nanoclays initially received the most attention as reinforcing fillers and as barrier enhancers in packaging and automotive fuel systems. Says Dr. Joseph Golba, lead scientist for reactive extrusion at PolyOne Corp., Cleveland (polyone.com), “The added barrier performance resulting from nanoclay formulations was insufficient to justify their higher cost. The value proposition was simply not there, at least not in enough applications. In addition, these materials proved not to be drop-in replacements for existing additives with respect to their processing behavior and application-critical mechanical properties.”

Adds Ned Bryant, senior product development engineer at RTP Co., Winona, Minn. (rtpcompany.com), “The biggest issue in their commercial progress in not only cost but related to processing challenges they pose in compounding formulations.”

Advances in surface treatment and other modifications continue to be made by pioneers such as Nanocor, Southern Clay Products, and Elementis Specialties. In the meantime, other types of submicron additives are making commercial strides. Says PolyOne’s Golba, “For barrier applications, we see nanoclays re-emerging, but with competition from other nano-additives such as graphenes.”

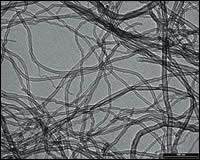

CARBON NANOTUBES STAKE CLAIM IN ESD

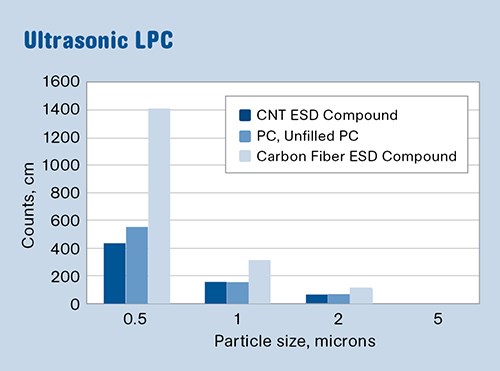

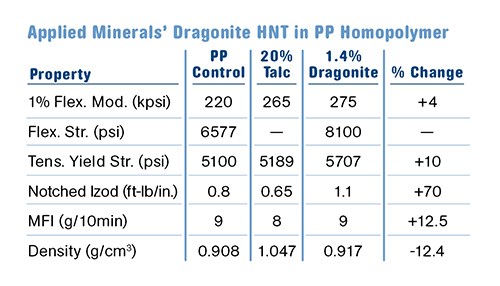

One type of sub-micron additive is gaining popularity in formulating electrically conductive thermoplastics: carbon nanotubes (CNTs), especially the more affordable and more widely available multi-walled variety, or MWCNTs. Leading manufacturers include Hyperion Catalysis, Nanocyl, Zyvex Performance Materials, and C-Nano Technology. More widespread availability of MWCNTs has resulted in lower prices—down about 33% in the last two years. As a result, MWCNTs are becoming more competitive with traditional electrically conductive additives, such as conductive carbon blacks. MWCNTs reportedly can provide better mechanical properties and ESD performance than is possible with carbon blacks.

Compounders like RTP and PolyOne have developed materials that incorporate MWCNTs for ESD applications in electronics. Several commercial uses are expected. Addressing the regulatory issue, RTP’s Bryant points out that manufacturers of CNTs have been wading through EPA requirements relatively well. “EPA has said that no two of these sub-micron additives are alike, so each company must do its own testing and get its own approval. Through good engineering and clean manufacturing, most have been able to secure approvals for their products.”

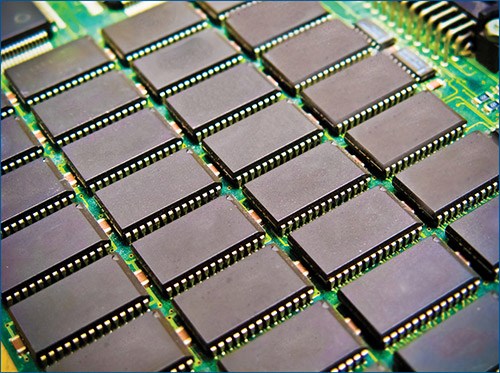

RTP’s commercial successes in this area are in electronics packaging. The main applications are shipping trays, primarily molded in Asia, that hold the various electronic components. RTP sells such compounds primarily of PC and PC blends, but some based on higher-temperature plastics like PEEK and PEI (Ultem). Although loading levels of MWCNT are mostly proprietary, typical use levels are generally under 5% by weight.

Other close-to-commercial applications of RTP’s MWCNT/thermoplastic compounds include blowers and fans used in electronics where both mechanical properties and ESD are required.

PolyOne’s Golba sees increasing use of sub-micron additives, driven by their ability to impart special functionality and performance attributes at relatively low loading levels. “Nanoaddditives and nanoadditive combinations, plus hybrid combinations of nano-scale and micro-scale additives, will add design flexibility for engineering specialty compounds and composites. The largest near-term uses for these materials will likely be in caes where ESD, EMI-RFI shielding, and barrier are critical to success. MWCNTs are the first line of attack for ESD, but expect to see more in the way of graphene and carbon nanofibers in the near future for these applications. It looks like it will be hybrid composites that will rule the day with respect to EMI/RFI shielding.”

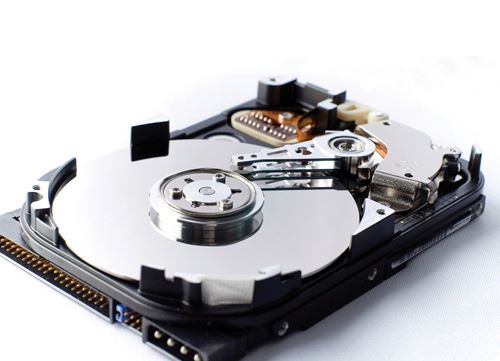

PolyOne’s commercial inroads with conductive compounds using MWCNT have been for ESD applications, the best examples of which are semiconductor carrier trays. Base materials have included high-temperature engineering thermoplastics such as PEEK, PEI, and polysulfone. A potential commercial application is a thermoplastic housing for hard disk drives where “super-clean” ESD performance is critical and where MWCNTs replace carbon fibers, which can be abrasive to sensitive disks.

Farther down the road, PolyOne’s Golba expects applications focused on flame retardancy, thermal conductivity, abrasion resistance, and structural property enhancements. MWCNTs also have been commercially used by nylon 12 resin suppliers and compounders for automotive fuel systems.

NEW CLAYS FOR ANTIMICROBIALS, O2 BARRIER

Engineered clays have often been limited to just one mineral (montmorillonite) and one modification system, and as such had limited dispersion compatibility in resins. The most common member of the smectite class of layered silicate or “platy” minerals, montmorillonite is an alumino-silicate whose individual platelets measure around 100 nm diam.

In recent years, Spain’s NBM has developed proprietary technology that includes a wider choice of minerals and modification systems, which have been shown to provide both better properties and futher potential to disperse these additives in a broad range of thermoplastics and thermosets. The company mines its own clays, which are not montomorillonite but have the same stacked silicate structure, and has developed its own purification and proprietary modification systems, according to Ole Faarbaek, vp for NBM in North America.

Among the first developments from NBM is the Bactiblock line of sub-micron, silver-functionalized clay antimicrobials. Silver-based antimicrobial solutions like BactiBlock continue to gain market share in plastics due to low dosing and broad-spectrum antimicrobial functionality, which creates an efficient protection against polymer degradation caused by bacteria, mold, mildew, fungi, and algae. Patented and EPA-registered, BactiBlock can be used as an additive masterbatch in a variety of molding and extrusion processes. In fact, NBM has newly entered into a partnership with RTP, whereby the latter will utilize Bactiblock in its line of antimicrobial compounds.

Jean Sirois, RTP’s general manager, touts Bactiblock for its unique clay carrier, which has been shown to create a very efficient delivery system for silver ions. This ensures fast-acting and durable performance, while being highly cost-competitive, he notes. RTP’s masterbatches with Bactiblock can be used at normal polymer processing temperatures and will soon be available in a wide range of polymers. Sirois sees the new masterbatches as an economical and easy-to-use solution to protect articles from degradation by microbial growth, making them ideal for applications in furniture, athletic equipment, personal-care items, office supplies, healthcare environments, and housewares.

NBM has had another recent major commercial breakthrough with its functionalized-clay oxygen scavenger. After three years of development in concert with EVOH maker Nippon Gosei, NBM’s O2 Block Barrier clay additive is now in commercial use. Nippon Gosei has exclusive use of O2 Block in its Soarnol NC series of EVOH compounds. The first grade, NC7003, has been shown to reduce the oxygen transmission of EVOH by 50% by adding a “tortuous-path” physical barrier. It’s sold here by Soarus LLC, Arlington Heights, Ill. (soarus.com).

Soarnol EVOH compounds boast the same processability and film properties as standard EVOH. The main target is food packaging that requires high oxygen barrier while maintaining clarity, says Faarbaek. “EVOH is challenged by high humidity. The clay additive fortifies EVOH by maintaining its properties at any humidity,” he explains. Other potential applications being explored by the two companies are retort packaging and fuel tanks. NBM is also investigating the use of its O2 Block Barrier additive in other polymers, including PET and biopolymers like PLA and PHB, which are sensitive to humidity during processing.

SUB-MICRON PET 'REHEAT' ADDITIVE

ColorMatrix, Berea, Ohio (colormatrix.com), now a wholly owned subsidiary of PolyOne, developed a sub-micron, inorganic reheat additive for PET, which is based on titanium nitride. Sold under the brand name Joule RHB, it has been shown to deliver superior aesthetic and reheat performance when compared with carbon black reheat additives. “By providing improved visual clarity, and maintaining that clarity through multi-trip recycling, Joule RHB has a positive impact on the recycling stream and contributes to the overall sustainability of the product,” says global regulatory manager Victoria Sayer.

Sayer points out that this additive has to be nano-scale in order to increase the surface area for heat absorption. “With a larger surface area only very small quantities are required. Materials are typically blue or black in color and hence absorb heat energy, making bottle blowing more efficient. If the materials were of a larger size, they would visibly color the bottle, which is not desirable in many applications that require transparent PET.”

Sayer also points out that ColorMatrix was the first company to petition successfully for a nano-material with the European Food Safety Authority for inclusion in EU regulation 10/2011 on plastic materials and articles intended to contact food.

Related Content

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreGraphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.

Read MoreMasterbatches Reduce Gloss in PLA and PETG 3D Printed Products

Insight Polymers & Compounding’s two low-gloss additive masterbatches shown to boost appearance of 3D printed objects.

Read MoreBASF to Purchase Pyrolysis Oil Produced From Waste Plastics

Agreement with Arcus Greencycling GMBH anticipates a volume of 100,000 ton/yr.

Read MoreRead Next

Carbon Nanotubes Improve In Properties, Purity and Price

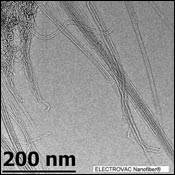

ew suppliers and manufacturing technologies continue to emerge in the burgeoning field of carbon nanofibers (CNFs) and single-walled carbon nanotubes (SWCNTs). Recent news includes North American availability of CNFs from Austria’s Electrovac Group.

Read MoreChasing Nanocomposites

Nano-sized particles have mega-potential in plastics because just a pinch does so much more than heavy loadings of other additives. Three recent conferences presented almost 200 papers on the feverish pace of ‘nano’ R&D on boosting plastics’ mechanical and barrier properties, flame retardancy, and electrical conductivity.

Read MoreCarbon Nanotubes Lots of Potential--If the Price is Right

With capacity scale-ups driving prices down, the pace has picked up for commerical applications that boost electrical and thermal conductivity, structural strength, and thermal stability.

Read More