Switch to Bioplastic Helps Molder ‘Go Green’

Labcon opts for surgarcane-derived HDPE to make its packaging more earth-friendly.

A move to a new line of biobased materials is helping a global manufacturer of laboratory disposable products further improve the sustainability of its product line. Labcon North America, Petaluma, Calif., recently switched to a “green” plastic for its “Earth-Friendly” labware-products packaging, and the result has been improvements in recyclability and manufacturing efficiency over previously used biomaterials.

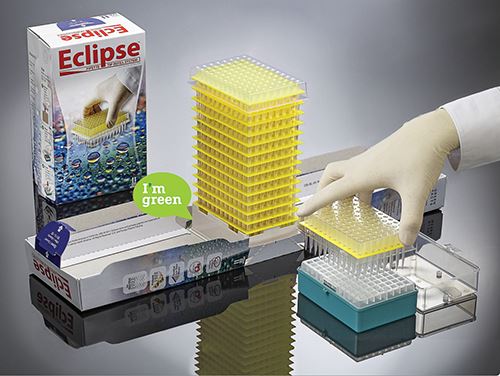

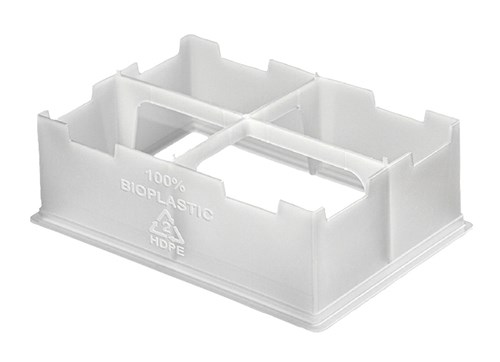

The material, “I’m Green” HDPE from Braskem of Brazil (U.S. office in Philadelphia), is produced from sugarcane ethanol. The material is used for Labcon’s low-carbon-footprint Eclipse pipette-tip refill system. The injection molded tip base of the refill package is made of this material, which can be recycled with conventional HDPE streams.

“Our end-users, as scientists, understand the need to reduce environmental impacts and consumption of the world’s limited resources, says Mark Gmelin, Labcon materials R&D engineer. “Braskem’s material helped us improve the product’s footprint, increase production efficiency, and provide a better end-of-life solution through recycling.”

Unlike the compostable PHA bioplastic previously used by Labcon, the Braskem HDPE has a life-cycle assessment (LCA) with certified CO2 footprint. For each ton of “green” HDPE produced, the material sequesters 2.15 tons of CO2 from the atmosphere. In contrast, typical polyolefins emit to the environment two times their own weight of CO2. Since “green” HDPE processes just like a traditional HDPE, it requires no drying, and cycle times are less than half those of the PHA part it replaced.

Labcon started focusing on disposable plastic labware in the 1980s. Its 80,000 ft² facility is equipped with 60 injection machines from 50 to 200 tons. It molds over 3 million pipette tips and about 1 million centrifuge tubes a day. Nearly 95% of these products are PP-based, with the rest (caps, for example) made of HDPE.

As Gmelin explains, the molder’s push toward sustainability began in 1994, when it opted to replace its PS packaging with recyclable paperboard and began selling its scrap plastic instead of landfilling it. These developments were accompanied by energy conservation and extensive on-site solar power generation. Today, all of its regrind is used in-house to make packaging components.

In 2007, the company developed an innovative pipette tip-refill system—consisting of 10 layers of pipette tips in a minimalist package with an integrated tip-loading device. This unique packaging motivated Labcon to consider bioplastics as part of its sustainable design, which includes recyclable paperboard, in-house regrind, and post-consumer PET.

Initially, Labcon chose PHA. “We opted for the more robust PHA over other bioplastics,” explains Gmelin. As he points out, the refill package base has thin walls (0.04-in) and dimensions of 3 x 5 x 2 in. with small alignment tabs that need to hold up well and withstand elevated temperatures during shipping.

Among the reasons Labcon switched materials is that the LCA didn’t look good once it started molding PHA parts. Most of its domestic and global customers have easy access to recycling operations, but not to industrial composting facilities. Moreover, there was a problem with material availability at times. In addition, the PHA—unlike PLA and Braskem’s HDPE—did not have third-party environmental certification, which Labcon’s customers often require.

Labcon plans to use Braskem’s “green” polyolefins for more molded parts in the future.

Related Content

Resins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)