Tandem Tools: New Twist on Stack Molds for Larger Parts

Two new tooling concepts adapt the idea of stack molds to producing larger parts that can be of dissimilar shape, size, color, or material.

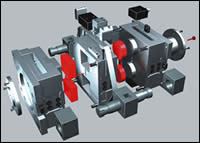

Two new tooling concepts adapt the idea of stack molds to producing larger parts that can be of dissimilar shape, size, color, or material. Husky Injection Molding Systems Ltd. showed off its new Tandem mold carrier at the NPE show in June. It mounts two conventional single-face molds in a stack configuration so that they open and close simultaneously. The system can operate with a single mold if needed, a flexibility conventional stack-mold systems don’t have, says Pierre Viaud-Murat, senior marketing analyst at Husky’s large tonnage machine plant in Dudelange, Luxembourg. That flexibility was also lacking in Husky’s older tandem concept, which used a dedicated machine and opened and closed the two mold faces on alternating cycles, unlike the new system.

Meanwhile, Injection Moulding Innovations Ltd. in Germany offers moldmakers a license to its TandemMould concept, in which the opening and closing of the different mold faces occur in a serial, or alternating, manner rather than simultaneously. This allows users to mold parts that require different injection and cooling profiles on the same machine. The two molding cycles overlap to increase productivity, says president Dirk E.O. Westerheide.

Both firms say their systems are best suited to large, flat parts and give the greatest productivity boost with thicker parts that cool more slowly.

Simultaneous molding

Husky’s Tandem System is offered on the company’s Quadloc two-platen presses and now on its Hylectric hydromechanical presses larger than 650 tons. The system has been an option on the high-tonnage Quadloc series for several months, but more recently became available on the smaller Hylectric line, which have an energy-saving electric screw drive. Compared with using two separate presses, Husky claims the tandem system provides savings of 15% in energy usage, 40% in floor space, and up to 50% in maintenance. However, cycle times are 5% to 10% longer owing to the larger opening stroke. Husky has sold about 25 of the new Tandem systems.

Husky’s tandem approach utilizes a center carrier plate with a support shoe that rides on the machine base. The company’s Z-shaped stack-mold linkage arm connects the moving platen, center carrier, and stationary platen to coordinate their movement. The linkage bar can be adjusted when parts of different depths are molded in the two faces. Since the system opens and closes both levels at the same time, the parts must have similar cycle times.

The system uses an extended-daylight clamp. The injection unit is offset to one side of the machine base. It feeds through a straight sprue bar directly into the center platen, from which melt is distributed via hot runners to both mold faces. This approach has a shorter flow length than standard injection through the center of the fixed platen and has fewer corners where melt can hang up. Decompression is also made easier.

The Tandem system can accommodate two-component or coinjection molding. In such cases, the two injectors are mounted side by side. One can inject directly through the fixed platen and the other through the sprue bar to the center platen.

The system can be converted to run a single mold by installing a dummy mold (spacer block) on either side of the center platen and closing the nozzle to the unused face. An alternative is to move the center platen against the fixed platen and inject into the single mold through the offset injection unit.

Alternate-face molding

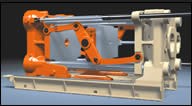

The TandemMould system from Injection Moulding Innovations operates each parting line alternately. Its center section has two rotating shafts with bayonet locks on each end (hardware that is supplied by the company). The bayonets mate with external locking bolts on the moving and stationary platens to lock and unlock each parting line. The shaft movements are synchronized by a toothed belt outside the center plate. The belt simultaneously locks one bayonet bolt while unlocking the other. The belt is actuated either by a core pull, pneumatic cylinder, or electric motor.

“Since one level is open while the other remains closed, the opening distance is the same as that on a standard mold,” says Westerheide. It also means that a larger injection unit is not needed, since only one mold is filled at a time. The system is supported with steel rods in the corners of the stationary platen and center section that connect to fittings on the center and moving platens.

The TandemMould system initiates a second molding cycle during the holding and cooling portion of the first molding cycle. “The machine does not open after the completion of the cooling phase but after the end of the hold-pressure phase in the other level,” says Westerheide. This allows increased cooling time that improves part quality without any time penalty.

Injection Moulding Innovations says its systems can be used on any standard horizontal press, even tiebarless ones. It can run with a hot or cold runner and can accommodate special processes such as gas assist, textile backmolding, in-mold labeling, MuCell microcellular molding, and two-component or sandwich approaches. TandemMould reportedly can cut tooling costs by 40%, floor space by 60%, and overall costs by 40%.

The TandemMould system has been used on various brands of presses from 20 to 2300 tons. Coffee-filter manufacturer Melitta of Minden, Germany, purchased the first two systems to produce vacuum-cleaner filter plates. Five TandemMould systems at Johnson Controls Inc. in Wuppertal, Germany, are producing automotive parts for GM’s Opel Astra. Three systems at Moellergroup in Bielefeld, Germany, make parts for BMW. Two more systems are on order from Schuberth Helmet, a German maker of racing helmets. “Since May we have more than 50 inquiries from molders serving the automotive industry, including one in California,” says Westerheide. He plans to establish a U.S. office next year.

Related Content

Hot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

Read MoreHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More