The 5 M’s of Molding—Part 4: Machine

Match your mold and material to the press to assure that your process control is not limited by poorly functioning machinery.

Match your mold and material to the press to assure that your process control is not limited by poorly functioning machinery.

Machinery/Auxilliary Equipment: The molding standard you set is highly dependent upon the machinery and auxiliary equipment you have available to you. Failure to properly assess the capabilities of your equipment will result in a poorly functioning production system. The following components strongly affect a facility’s scrap, downtime and productivity:

- Press: Molding machine capabilities are crucial to the design of any manufacturing system. Press tonnage and screw design (such as general purpose vs. nylon) are key factors in process consistency. Match your mold and material to the press to assure that your process control is not limited due to poorly functioning machinery. Also utilize your process data to further assess process control and machine problems.

- Robot: Robotics systems are a valuable asset for establishing production and quality systems. When evaluating the production system, always review potential fixes through robot improvements, end of arm tooling or programming changes.

- Automation: Other sources of automation should also be reviewed. For instance, if a quality concern keeps repeating itself, look for solutions through automation development. Involve everyone on your production team to fully assess what failures exist within the production system and utilize your engineers to develop working solutions. Better equip your operators and personnel to remove problematic conditions from the production equation.

Preventative maintenance is a key measurable in the Machinery/Equipment category. Unscheduled downtime seriously impedes production efficiencies due to the nature of unexpected system failures and the resulting unprepared approach towards resolution. Scheduled maintenance events are by far the best way to prevent poor performance. Here are some of the areas where preventative maintenance can prevent unscheduled break downs. Each of these components should have their own maintenance log to help establish what concerns are and what frequency of inspection needs to be:

- Molding machine: Press breakdowns can be avoided with a regular inspection system in place. Here are some of the primary inspections and a recommended frequency for performing them:

- Hydraulic Fluid- Quarterly: Fluid samples should be taken and sent to a screener to evaluate metal content and viscosity break down.

- Hoses- Weekly: Inspect hoses for signs of wear, rubbing or blistering.

- Screw- Bi-Annually: Remove screw for inspection. Measure flights and shank to determine whether wear is becoming an issue. Also measure the metering zone of the barrel to verify condition.

- Electrical-Weekly: Look for unsafe conditions and integrity of connectors.

- Heater Bands- Monthly: Verify that all bands are in working condition

- Tooling- It is important to note that a simple 10-minute inspection of every mold per shift can identify problems and prevent hours of down time due to dry slides, pins, etc. Keep detailed records of mold repairs and use them to develop preventative maintenance events and timing. In a short-run shop, simple teardown and cleaning should occur after every run. In cases where molds run for extended periods of time, regular inspection should occur and molds should be torn down and cleaned bi-weekly. In all cases, cleaning frequencies should be developed based on mold history to prevent breakage through intervention and care.

Garrett MacKenzie is the owner and editor of www.plastic411.com. Mackenzie started in plastics at the age of 19 as an operator, eventually moving up through the ranks to engineering and management over a 29-year timeframe. He currently works as a plastic injection consultant in engineering and training capacities. He can be contacted at garrett.mackenzie@mail.com.

Next week, Part 5 in The Five “Ms” of Molding: Method

Related Content

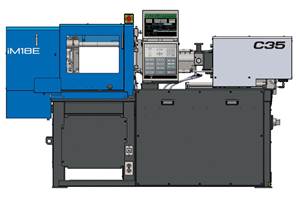

Compact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

Read MoreConsistent Shots for Consistent Shots

An integral supplier in the effort to fast-track COVID-19 vaccine deployment, Retractable Technologies turned to Arburg and its PressurePilot technology to help deliver more than 500 million syringes during the pandemic.

Read MoreFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)