The Cost of Doing Nothing

Tooling Know How

Most people usually associate costs with doing something.

Most people usually associate costs with doing something. Replacing tooling, cleaning molds, fixing things, etc. But actually, the highest costs come from doing nothing.

How can that be? Well, doing nothing means that repair work comes in the form of unscheduled events, which experts claim cost four to five times as much as scheduled work. In a reactive-maintenance strategy, molds only get worked on when they squeak, leak, break, or make bad parts.

In a typical mold-maintenance environment, the daily work load comes from several directions:

•Mold breakdowns: Emergency repairs.

•Cavitation drop-off: Fix a mold that is running 40 of 48 cavities.

•Product/part quality or function issues: Customer complaints.

•Tooling needs: rework, alterations, new tooling, based on mold function requirements.

Other mold performance issues come from unstandardized practices in areas such as

•Bench work: How does it come apart?

•Documentation: Don’t just write down “needs repair” and “done.”

•Mold rebuild or fabrication work: Is everything to print?

As shown by all these potential issues, shop managers don’t need to look for work—it will come to them. And the less that’s done proactively, the more that must be done reactively. In other words, we have no idea when or what mold-maintenance needs will arise because we are not in control—the “maintenance Gods” are.

A reactive style of maintenance management has tool rooms simply waiting for the next problem to land on someone’s bench—and it will, of this we can be sure. If you run it, it will break. And the work order will simply state: “Just fix it, please.”

This is the real cost of doing nothing. Problems keep coming with no means of forecasting when or the severity of the issues. We wait and then react. The “do-nothing” culture feeds on many seemingly logical reasons, or excuses: “We have no time, tooling, or people to be proactive.” Doing nothing is so endemic in some companies that “hero cookies” are awarded when breakdowns get fixed and the molds are put back into production. Never mind that the breakdown should never have occurred in the first place. It doesn’t matter now—the mold’s running, so we’re OK.

Don’t get me wrong, the do-nothing culture was not born of laziness; down deep, everybody wants to do a good job. It’s more the result of not fully realizing the benefits of being—nor understanding how to be—truly be proactive. It’s like everything else in this world, buying into something new is about being able to recognize the value proposition. Maintenance improvements can be a difficult sell, especially since maintenance is a “process” where one cannot physically hold the value in one’s own hands and feel the weight or the heft of it. If we could, a reactive culture would feel flimsy and cheap and would be quickly dismissed as a waste of time.

So who’s at fault? A major part of the blame sits squarely on the shoulders of the type of work-order systems we use where maintenance “stories” are entered instead of usable data. It’s difficult to measure or quantify the words in a “story.” So this means we can’t count, compare, target, or forecast ongoing issues from a mold’s maintenance history. Documentation is a tool and should be a major part of daily maintenance planning. There is no substitute. Imagine taking film study away from a football team—what would be the outcome? Basically, a coach would say, “Go out there and score some points, boys!” He couldn’t tell them how or what might prevent them from doing so.

In a maintenance culture that rewards hindsight and reactive decision making, where does the motivation come from to move into a proactive form of management? It comes from a higher power, called profit. The fact is that there is a ton of money (profit) that separates the perfect maintenance scenario from the reality of the typical repair shop. But it gets doled out in small, undetected amounts.

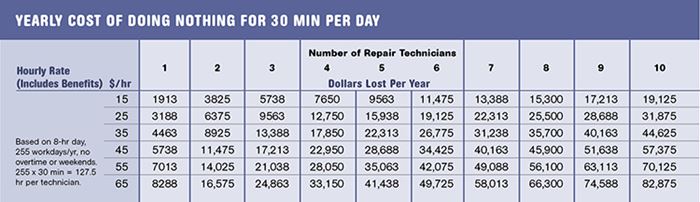

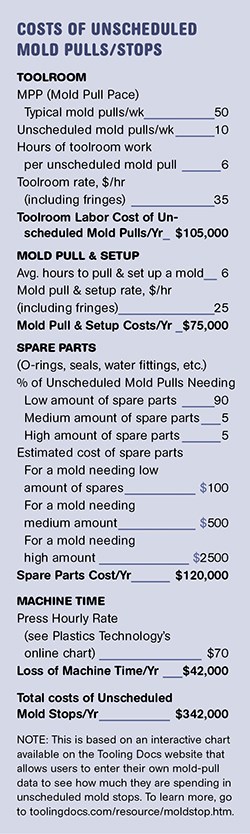

To recognize how much we need to move into a proactive, defect-targeting mold-maintenance culture, we need tools that will shine a light on the money that doing nothing costs us. The table to the right breaks down those costs. (A similar table on the Tooling Docs website allows you to insert your own cost values.) The table to the right shows how much money a typical shop could save by improving its processes enough to gain an extra 30 min each day per technician by reducing unscheduled downtime.

The objective in a perfect maintenance scenario would be to:

•Never have unscheduled downtime. All work is planned.

•Replace or rework all tooling and mold components before bad production, excessive wear, or lock-up.

•Accomplish all work accurately, safely, and as planned—no wasted time through unstandardized and non-value-added methods or practices.

If we could accomplish all this, it would mean the related costs concerning the above three points are included in the piece price instead of being the “cost of doing business,” as is all too typical today.

Continuing to focus only on getting broken molds back into the press is a never-ending spiral that will keep companies bogged down in mediocrity yet feeling good about the effort applied. Learn to look beyond the next breakdown and start gathering data on high-frequency/high-cost issues to see where opportunity lies to reduce or eliminate the problems altogether. Doing something means striving to avoid issues—not just reacting to them.

About the Author

Steven Johnson is the operations manager for ToolingDocs LLC, part of the PCIC Group of Companies. Steve also has is own business, MoldTrax in Ashland, Ohio. He can be reached at steve.johnson@toolingdocs.com or (419) 289-0281

Related Content

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)