Time for a Switch to Electric Heater Rolls?

Web processors and converters who use liquid-heated rollers for orienting, annealing, laminating, and embossing should take a look at recent advances in electric-heated rolls. You could get better temperature control with less maintenance and downtime.

The latest heater rolls for web processing make possible improved product quality, machine throughput, and uptime. Orienting, annealing, laminating, and embossing operations still typically use rollers heated with oil, water, or steam. But liquid-heated systems, by their very nature, present challenges in maintenance, safety, temperature control and uniformity, and energy usage.

High-performance electric heater-roll systems have been developed to address these challenges. Electric systems use simpler components and direct-line voltage, eliminating the need for a remote heat source and reducing maintenance and downtime.

Today's electric heater rolls also provide precise temperature uniformity across the face of the roller to maximize product quality and web-handling performance.

One proven type of high-end electric system, based on induction heating generated by rapidly alternating magnetic fields, has been available for decades. Advances in the last three or four years in resistance-heated roll technology offer an economical alternative with the same performance benefits as induction systems. This overview of heater-roll choices places the latest advances in context of cost, processing performance, maintenance, and safety.

Where they are used

While some web-processing applications require rollers that can both add or subtract heat (calendering, for example), the downstream converting applications discussed here use rollers for heating only.

Machine-direction orienting of a substrate may require raising web temperature from just a few degrees to a lot more, depending on the desired result. Temperature uniformity and control are critical so that the material stretches evenly and remains wrinkle-free.

Annealing or stress relief involves heating the film or sheet after it has been chilled. The goal of temperature control here is to eliminate distortions and imperfections and produce a clearer, stronger web.

Laminating uses heater rolls either to activate an adhesive or soften the web itself so it will bond to another material in the laminating nip. Most adhesives used in laminating are activated at 200-300 F. Hot-melt adhesive bonding usually has a wide temperature window to allow melting the adhesive without blistering the laminate. Thermal laminating of two or more substrates can require much more precise temperature control. The obvious pitfall of improper heating is inadequate bonding.

Embossing a substrate is often done downstream after the material gauge and width are established. Heater-roll temperature control and uniformity are important, but so are pressure and line speed.

Drawbacks of liquid heating

Though most heater rollers are specified to achieve a certain temperature uniformity under no-load conditions, roll-temperature uniformity can vary during operation, depending on line speed (related to thermal load) and web width (related to load distribution).

Liquid-heated roller surfaces will naturally rise close to the internal roller temperature where there is little thermal load outside the web. But without some mechanism such as a heat pipe, the roller tends to be hotter at the ends than in the web path, sometimes causing the web edges to overheat. This excess heat can be redistributed by a heat pipe, which automatically transfers heat from hotter to cooler regions by evaporating and condensing a fluid along the length of the pipe.

Most liquid systems use a remote reservoir and heating element to heat the circulating liquid. They also have a controller and sensor at the tank to set the temperature and operate the system, plus a pump, rotary connector, and plumbing to transfer liquid to the roller.

Liquid-heated rollers consist of either a simple single shell or more commonly of a spiral-baffled, double-walled roll to maintain more consistent thermal transfer across and around the roller. In either case, the roller is heated from the inside out, so the surface is the last part to reach the desired setpoint. Temperature is usually monitored at the heated-liquid sump, not at the roll, which makes roller temperature adjustment a trial-and-error process.

Also, liquid systems lose an estimated 10-15% of their heat during the transfer from the reservoir to the roll.

The vast majority of preheating, laminating, and heat-stretching applications use oil-heated systems because of the medium- to high-heat requirements of these processes. However, disposal of carbonized oil after thermal cycling is a continual challenge for users. Carbonized oil also restricts flow and coats the internal surfaces of the roller, hoses, pumps, and filters, which reduces heat transfer. Heat not only causes the oil to break down, it causes hoses and bearings to wear out more quickly. However, new hydrocarbon oils have recently become available that reportedly handle higher operating temperatures without degrading.

About 20-25% of heated rollers today use water or steam. Generally, water is used for low-heat applications (below 200 F), while steam is used for medium- to high-heat applications. In both cases, internal corrosion or scale deposits can reduce heat-transfer performance. A high-temperature steam system may require a gas-fired boiler to generate sufficient heat, creating a pressure vessel that needs regular inspection and repair.

Electric-heat alternatives

Electric-heated rollers are currently a minority of the market but offer several advantages. Except for ceramic types, electrically heated rollers are heated internally, resulting in a higher internal temperature than surface temperature. Because these rollers are generally controlled by measuring the shell temperature from a thermocouple embedded near the surface, they are much more easily and quickly controlled than liquid-heated systems. The sensor signal is sent to the temperature controller, which controls power to the heater element.

Thermal losses are limited to normal convection from the roller surface, since all heat is produced internally. Temperature recovery is faster than with liquid heating because of the finer degree of control and higher watt density. Both induction and resistance heating systems can be retrofitted in many operations currently using liquid heating.

Induction-heated rollers have been used since about 1970 but have become more popular in the last few years because they provide a high degree of thermal precision and stability compared with liquid systems.

A combination of induction and heat-pipe technology generates heat on the inside surface of the outer roller shell by exposure to a high-intensity, rapidly changing magnetic field. Induction coils are mounted on a non-rotating shaft, close to the roller shell. The outer shell contains heat pipes to distribute heat across the roller.

Operating temperatures with induction heating go as high as 788 F, meeting both low- and high-heat application needs. The electrical connection is made to the stationary coil, but a rotary transformer is required for temperature sensing. A high-frequency generator drives the induction-heating coils. Designing such systems is usually beyond the capabilities of plant engineering departments, but induction-heating specialists are available to help with purchasing and installation.

Resistance-heated rollers had a poor performance reputation in the past. Early models used low-end cartridge heaters that had a high rate of failure. However, in the past three to four years, newer resistance-heat technology provides comparable performance to induction heating.

One advanced type of resistance-heated roller incorporates high-performance cartridge heaters in the innermost layer of the roller. A thermal-equalization chamber (or specialized heat pipe) surrounds the inner layer to distribute heat evenly across the roller surface. These rollers can provide uniformity within ±1.8° F (1° C) at temperatures up to 500 F, suiting them to a wide range of web-heating applications.

Instead of heat pipes, other modern resistance-heating systems use a technology similar to cartridge heaters but with multiple heat zones to control temperature uniformly. These systems reportedly can run at up to 1000 F.

Ceramic heater rolls use a second type of advanced resistance heating, consisting of a variety of ceramic materials applied by thermal spray to the outer surface of the roll core. One of the ceramic layers is actually an electrical resistance heater. When combined, the ceramic materials form a thin, homogeneous insulated heater element that covers the entire roller surface and generates precise levels of radiant heat.

Here, too, a thermal-equalization chamber provides continuous leveling of the surface temperature across the face of the roller. Ceramic systems can provide temperatures up to 350 F with uniformity to within ±1.8° F.

Because the ceramic heater roll generates heat right at the roller surface, it is not necessary for the entire core to reach process temperature before production can begin. Temperature is measured at the point where it is generated via a non-contact infrared sensor, allowing superior temperature recovery and control. This is the only known system, liquid or electric, to eliminate setpoint overshoot. Since the core is actually cooler than the roller surface, this system is somewhat more efficient than internally heated systems.

With both types of resistance-heated systems, external electrical connections to the roller are normally made through only one journal using a rotary electrical connector. The average plant engineer can set up the electronic controls, which are also available from the roller supplier.

Resistance-heated systems are also significantly more economical to buy and are available with shorter lead times than most induction systems, which come from Japan. Operating costs of resistance and induction heating systems are comparable.

Bruce Hyllberg is a research specialist at American Roller Co. in Bannockburn, Ill. He designs and develops electrically heated rollers for printing and converting. Also contributing to this article were Jon Glidden, market development manager for advanced hard-coat rollers, and Randy Mittelstaedt, manufacturing engineer for the Arcotech specialty roller division.

Related Content

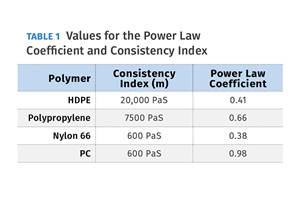

The Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreFully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreHow to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More