Tips and Techniques: Optimize Your Robot With the Right Controls

Just because you have robots operating in your plant, don’t assume that puts you ahead of increasing domestic and global competition.

Just because you have robots operating in your plant, don’t assume that puts you ahead of

increasing domestic and global competition. What was top performance yesterday might be uncompetitive today. Many robots in molding shops are “going through the motions” but are not giving the molder the competitive edge needed to cut costs and boost profit.

Most molders know that robots can offer savings by removing labor from “the gate,” performing secondary operations, segregating parts, boxing, inspecting, etc. But it’s important to keep current with today’s new robot technology. New control and programming software tools are being implemented continuously by suppliers. These tools can help simplify control, enhance performance and flexibility, improve communication, and reduce maintenance.

When assessing your production work cells, a casual glance on the molding floor may indicate that the robots are doing “pick-and-place”—

demolding and placing parts—just fine. But a well-trained eye might see wasted cycle time in the mold area and a robot waiting over the mold when it could be adding value by trimming, boxing, inspecting, or assembling parts.

Further, an expert eye might see robots that are not “curving” (interpolating motions to shorten the overall work path), or are under-controlling interlocks—i.e., the robot’s ability to control a mold’s sequence such as ejector motion, mold open/close permissions, or interlocks for other downstream devices. These robot control limitations might arise because the technical staff simply does not have the training to optimize the robot cycles to a high level, but it could also be because the robot itself is “control limited” and better suited for simple pick-and-place and not much else.

A few years back, molders used to brag of having robots that were well-maintained and lasted 12, 14, 16 years or more. But because of the rapid change in robot technology, a robot more than seven to 10 years old is more likely making the molder less competitive by not optimizing the possible cost benefits. Even though those older robots have been through the accounting cycle and are “paid for,” they should be replaced if maximum performance and output are important to you.

Newer robots are faster, have less downtime through improved reliability and communication capability (messaging and networking), offer better communication to the operator (user graphics and interface simplification), and can perform 3D motions that conserve energy while reducing cycle time. In some cases, the robot can optimize 3D work paths automatically, a new leap in technology.

THREE LEVELS OF CONTROLLERS

Robot controllers are generally available today in three levels:

- Simple non-graphical alpha-numeric controllers with a small LCD screen.

- Full-color touchscreen, graphical user interface (GUI), icon-driven. Primarily used for “teaching” or some form of limited proprietary programming, but without fully open CNC custom programming control. Generally called a “canned” controller.

- Full-color touchscreen, GUI, icon tools, and on-board fully open, “true” CNC, line-by-line user control with on-board instant “help” manuals.

The distinction of the highest-level controller is that if all these features are well done, the molder will not have to go back to the supplier for new programs or program changes. The molder has the flexibility to take on future application needs and is empowered to make unlimited custom changes on its own and without additional cost.

Let’s examine some older versus newer (basic vs. advanced) robot control technology for injection molders to consider:

DEMOLDING TIME OPTIMIZATION

The idea is to reduce the robot picking time “in the mold,” which offers molders a great opportunity to cut costs and increase throughput with faster machine cycles. Remember a demolding time reduction of just 1 sec can increase molding machine output greatly.

For example, saving 1 sec on a 15-sec cycle running 8 cavities will yield an increase in production of around 1 million parts/yr (based on 330 working days). Factor this improved performance across several machines, and you might gain enough additional output to negate the need for another press. Where do your current robots and setups rank on the following scale of “Good, Better, Best”?

Good:

- The mold open daylight is minimized and velocities and cushions are optimized to minimize the time the robot’s arm is in the mold.

- Ejector stroke and velocity are optimized to minimize the capture time of the part from the ejectors by the robot end-of-arm tool.

- The robot kick stroke forward and back are minimized in coordination with the ejector stroke.

Better: All of the above, plus…

- The end-of-arm-tool is designed to minimize capture time—i.e., using the correct vacuum cups and plungers (minimized plunger stroke) or gripper type, especially important for cycles under 20 to 30 sec. Note: Vacuum end-of-arm tools generally demold faster than gripper types, are less expensive, and weigh less. Use them when you can.

- J-motion (radius) in and out of the mold area is employed, instead of time-wasting right-angle “L” motions.

- The main arm is staged with minimum but safe clearance above the mold to minimize its demolding stroke in and out of the mold area.

Best: All of the above, plus…

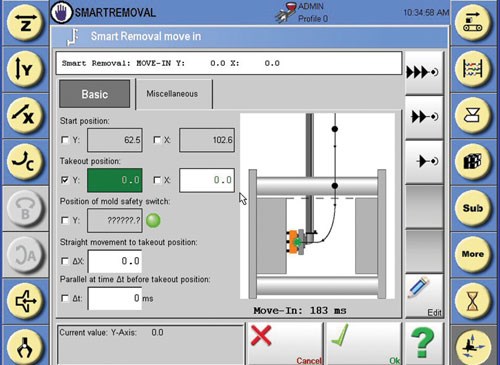

- “Running Start” (see Fig. 1)—a software tool that starts the robot main arm moving downward before the “mold-open complete” signal in order to minimize take-out time by being positioned better in the robot’s main-arm acceleration curve. The robot actually moves no faster in terms of peak velocity but moves faster for a longer period of the overall take-out time. This can easily shave 10% to 15% off cycle time of a good setup. Top robot suppliers have this safe demolding control available on the pendant and can show a video clip demonstration of how it works.

- Press-integrated position control coordinated with the robot. This allows the robot to enter the mold-open area before the mold-open-complete signal. The molding machine communicates to the robot its position and the robot can then safely enter “early,” thus saving time. It can do so on the way out as well. This can save 5% to 10% of cycle time but requires careful integration of the molding machine and robot control and good communication between the press and robot. This technology is better accomplished on servo-electric molding machines or by suppliers who can integrate these functions. For example, some firms supply both robots and presses.

USER INTERFACE & PROGRAMMING

The idea here is that by giving the molder more control power, the robot’s capability, flexibility, and performance go up accordingly. Where do your robots rank on this scale?

Good:

- Graphical user interface takes advantage of graphics to communicate easily to the user and to ease control navigation.

- Touchscreen reduces time-wasting scrolling and allows for on-screen “soft” buttons for flexibility in teaching/programming.

- Icon-driven control is great for simple pick-and-place applications but can limit control flexibility if it is the main or only user interface. “Over–iconing” is a common negative result of a controller that relies too heavily on graphics to teach and program a routine.

Better:

- Dual control platforms: The robot controller offers the user both graphical icon-driven control and also some type of CNC control for more demanding applications.

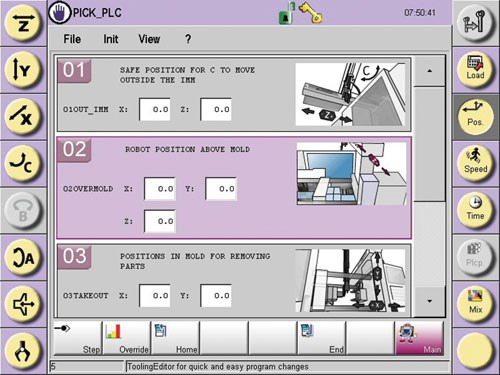

- Editing features (Fig. 2) provide simple methods to edit programs and sequences and allow users to optimize cycles and to program simple custom applications beyond pick-and-place. Simple adjustment of speeds, positions, and timers are the minimum needed to edit each robot stroke and motion.

Best:

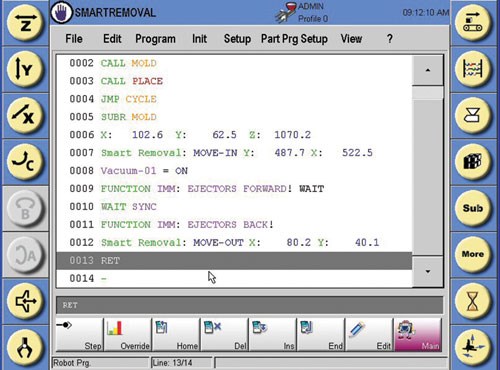

“True” fully open and complete CNC control is the highest standard of control. It makes the difference between a robot that is flexible and fully programmable vs. a quasi-dedicated device. This is a step-by-step (line code) control in series or parallel whereby the user has complete control of not only the sequence, positions, speeds, timers, and I/O, but also mold sequences and downstream-equipment interlocks, encoder feedback, curving motion, and 3D movements.

The progressive custom molder needs this “line code” CNC tool (Fig. 3) for total flexibility to take on the most demanding value-added applications that other molders cannot handle due to lack of robot expertise or use of older, more “canned” type of robot controls. If you have to go back to your supplier for program changes then you probably do not have this level of control.

ROBOT MECHANICS COUNT, TOO

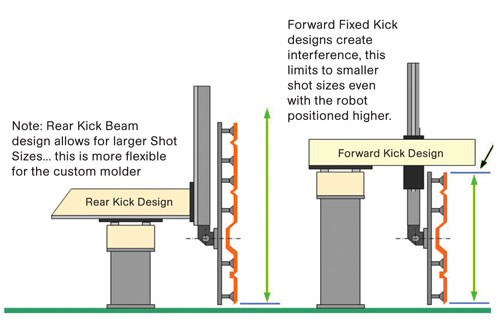

Going forward, most of the advances in robot technology will be in the controls. But mechanical differences and changes can be important as well. For example, when considering a replacement robot, you might want to take advantage of a kick-beam design that is not limited in part-length handling capability (Fig. 4).

Lastly, because optimizing your robot might mean replacing it, you may want to select a vendor that can supply more than basic end-of-arm tooling. During its life the robot will need to be retooled and reapplied many times, and a solid value-added supplier will gladly help you do this. Molders will benefit from a robot supplier that sells more than just the upfront hardware, and also supports the robot for future applications throughout its life.

About the Author

Joe Varone is the southeast regional sales manager for robots at Wittmann Battenfeld Inc., Torrington, Conn. He started as a robot and systems builder in 1991 and advanced into field service and technical sales positions. He joined Wittmann in 2006. Contact: (860) 496-9603; wittmann-group.com.

Related Content

Automation Evolution: From Robots to Work Cells, Solo Devices to Integrated Systems

Injection molding automation has progressed from devices to systems, from simplicity to more complex capabilities. The author traces this development through various levels of automation – all still available choices today – and analyzes the costs and capabilities for each level.

Read MoreNew Technology Enables ‘Smart Drying’ Based on Resin Moisture

The ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreDrones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

.png;maxWidth=300;quality=90)