TOOLING: Mold Simulation Software Gains Speed & New Functionality

Enhancements in simulating conformal cooling, hot runners, MuCell foaming, shrink/warp, and fiber reinforcements.

New release R13.0 of Moldex3D injection mold simulation software (U.S. office in Farmington Hills, Mich.) is faster than ever and offers a host of new features for easier and more sophisticated meshing, modeling, and analysis. These include better control over heating and cooling analysis, expanded simulation properties for special molding processes (such as valve-gate and multi-component molding), enhanced prediction tools to improve part quality (such as fiber reinforcement simulation), and a substantially expanded and updated materials database.

• Faster meshing: Analysis of large and/or complex molds will benefit from an average of 61% faster generation of tetrahedral meshes, measured on models from 515,000 to 20.5 million elements, vs. the last release (R12). The last release introduced a manual method of selectively increasing mesh density in critical areas, such as around small features or areas of curvature. R13 contains new automatic mesh “seeding” for that purpose. New automated tools also guide users step by step through correcting common mesh errors. These include a Fix Wizard, Fill Hole Wizard, Unfillet Wizard, and a Trouble Point Repair Tool, which detects where the mesh density is insufficient in very thin areas of the model.

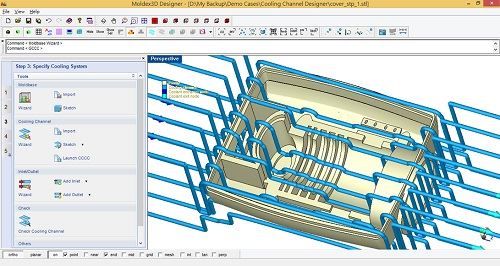

In previous versions, mesh generation for multi-component molding was tedious because users had to manually match the contact faces of the second shot and the first shot or insert. A new tool displays where the two contact faces don’t match and then automatically matches them. Also unlike the previous release, R13 now allows users to import runners and cooling-channel geometries directly from CAD for solid meshing. That greatly enhances users’ ability to model complex conformal cooling layouts.

R12 introduced the proprietary Boundary Layer Mesh (BLM) as a means of high-resolution meshing of complex 3D geometry. Now, R13 extends BLM technology to support more analysis types—multi-component molding, powder injection molding (PIM), MuCell microcellular foam molding, gas and water assist, compression molding, conformal cooling, and coinjection.

• Cooling enhancements: R13 now supports 3D cooling analysis with multiple inlets and outlets and can display the Reynolds number of each channel. That value indicates turbulence and efficiency of heat transfer.

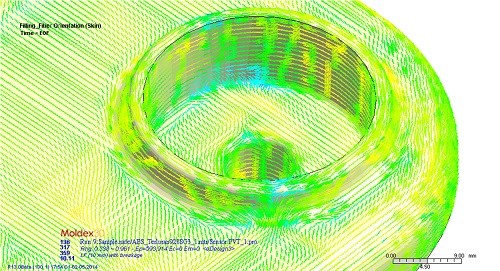

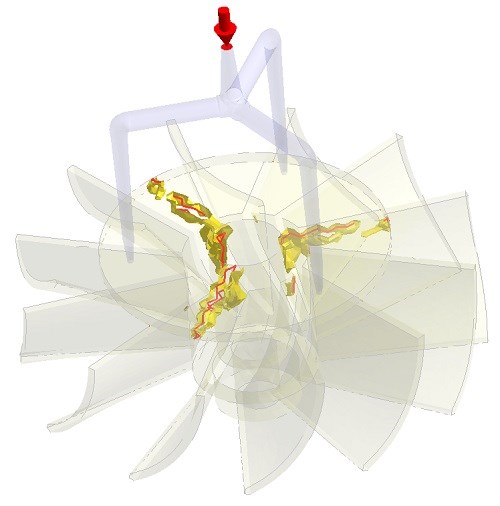

• Fiber reinforcements: The Fiber module has been enhanced to take into account fiber-length degradation in the screw as part of its calculation of fiber-length distribution in the finished part. (Input of screw data is required.) Also new is modeling fiber concentration distribution throughout the part. A new display option makes it easier to visualize fiber orientation in the part. By default, Moldex3D displays the fiber direction in every mesh element. But large numbers of mesh elements can obscure the overall trend. A new “sparse” display mode displays fiber orientation more selectively to make the overall result more easily visible.

• Shrink & warp prediction: V13 now allows users to separate the effects of differential shrinkage throughout a part—caused by differing shear stresses and thicknesses—from the effects of differential temperature in the part, which also affects shrinkage and warpage. The latter factor can more easily be adjusted by changing the cooling layout.

Moldmakers can adjust for shrinkage and warpage problems by adjusting the part dimensions, but this often requires tedious trial and error. R13 provides a faster solution by means of a new Shrinkage Compensation Setting, which allows users to set the mold compensation in x-y-z directions and see the shrink/warp results in real time.

• Hot-runner simulation: While Moldex3D previously supported valve-gate simulation during the filling stage, R13 now adds the ability to model the effects of valve closing during the packing stage. R13 presents a control panel for each valve gate to open and close it based on time or flow-front position.

In the past, manual mesh development was required to define the insulating air gap between the mold base and hot runner manifold, which could be very time consuming due to the large amount of tiny meshes. For easier meshing, R13adds auto air-gap detection to the solid standard cooling solver.

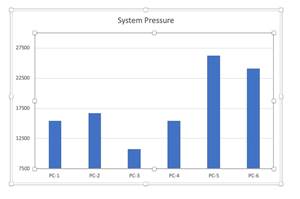

Also new are the ability to model the internal temperature distribution within each hot runner, and up to 100 times faster verification of the heating performance of heating rods and coils in the hot-runner system.

• MuCell foaming: The new release supports the core-back process for MuCell foaming, adds packing simulation for MuCell, and supports integration of MuCell results for cell size and density with structural analysis software.

• Other enhancements: Melt-front display can now be determined either by time, as before, or now by ram position.

In molding highly filled parts, such as in PIM, or optical parts with a high surface requirement, wall slip is a common occurrence that affects mold filling and pressure. R13 offers a new option to consider the mold surface roughness to calculate wall-slip phenomena for better prediction of filling pattern, pressure variation, and surface defects.

Improved weld-line prediction now displays weld lines inside the part and not just on the surface.

For gas- and water-assist molding, R13 allows the overflow wells to be opened and closed by time, and water assist is made more accurate by allowing user input of water flow rate.

Mold Preheat Analysis now lets the user predict when the mold will reach a steady-state temperature after startup.

For heat-cool molding whereby the mold surface is preheated by induction, flame heating, or other method, R13 allows the temperature of the mold surface to be set separately for the start of each cycle.

New Mold Deformation Analysis calculates the effects of filling pressure and cooling stresses on the mold and the part.

The Gate Location Adviser has been enhanced with several features to give more useful advice, such as ability to designate constraint regions where the gate cannot be located.

The Process Wizard now includes simulation of the graphical user interfaces of machines from Arburg, CLF, Fanuc, Fortune/Victor Taichung, Mitsubishi, and Niigata. The machine database has also been enhanced by the addition of shot capacity.

Related Content

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreInjection Molding Simulation Meets the Real World

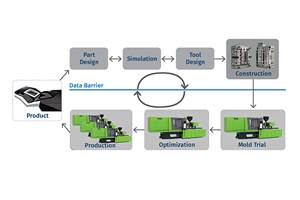

Direct data interface between molding simulation and the injection machine links the computer model to the real-world process. This can improve results from product and mold design through ongoing production. A case study demonstrates these benefits for automotive components in a family mold.

Read MoreHow to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)